Such a roof is very often used in the construction of modern multi-storey residential buildings, as well as industrial buildings and office buildings. However, it is also used in suburban construction, although in this case most often for outbuildings, but for a low-rise apartment building, the installation of a flat roof is permissible. This article is the subject of this article, which will highlight various points regarding the installation of such structures.

Content

Flat roof device

The construction technology of this design does not differ in increased complexity, so if you plan to cover a garage or an outbuilding, then you can easily cope on your own. The roof device involves the use of metal or wooden beams, which will evenly distribute the load from the structure on the surface of the bearing walls. The roof must withstand:

- the total weight of the structure and communication elements located on the roof;

- the weight of the person performing the maintenance or repair of the coating;

- a lot of snow falling in winter;

When calculating the reliability of the roof structure, it is necessary to take into account that the snow load can be quite large, because there is no slope, due to which part of the snow mass could fall down.

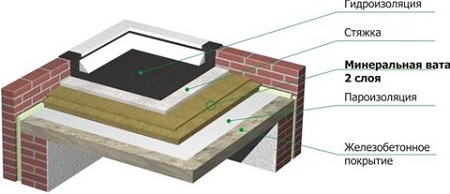

The basis for a flat roof is most often reinforced concrete. This can be a monolithic design, and a hollow floor slab, on top of which the elements of the roofing pie are laid. On top of the concrete is a waterproofing layer on which the insulation lies. The insulation material itself is protected by a second layer of waterproofing located above the insulation.

Roof technology for various types of rooms

The way in which a flat roof will be created with your own hands depends on its purpose. In this case, all types of similar construction are divided into two categories. The first includes roofs for unheated rooms, and the second those that are used for heated.

When the volume of construction is small, for example, you need to make a garage, a barn or even a small one-story house with a flat roof, it is quite possible to do it yourself, but for large areas it is already necessary to attract helpers.

An unheated room can be created with a roof located on a slope. Even a slight angle of inclination will allow the water to drain, and melted snow will be much easier to remove. The roof structure may be a set of load-bearing beams over which a continuous shield of boards is laid. Already on top of the boards are several layers of roofing material, which acts as a waterproofing. It is worth saying that this type of roof is characterized by minimal labor costs, and there is not much material needed to create it, however, the service life of the structure will be short, and even then, provided that there is no heating in the room.

When attaching the roll material, it must be taken into account that it needs to be fixed every 70 cm, but not with rails to create barriers for precipitation flowing down along the roof surface. The minimum slope so that water flows under the action of gravity is better to choose at least 3 percent.

If you plan to use this room and heat it, it is worth thinking about the second version of the roof - insulated.In this case, the roofing cake is assembled from several layers, which allows to ensure the proper level of thermal insulation, as well as protect the heater itself from the ingress of water in one form or another.

The flat roof, the section of which is presented in the figure below, is just designed for insulated rooms.

There are a lot of technologies for creating such structures, and some of them will be discussed below, and for self-production it is best to use the simplest option. In this case, the beams again act as the base, on top of which the flooring from the boards is placed. Lining roofing material is laid on them, and the rolled material must be placed with 15 cm overlap. On top of it, it is necessary to backfill expanded clay insulation, slag, etc., and in this case we should not forget which direction the slope for the water flow will be.

The insulation is leveled, and a cement screed is made over it, 2-3 cm thick. This is necessary in order to avoid accidental damage to the roof during snow removal. When the screed is set, it should be treated with a bitumen primer, and only then start sticking the roll carpet.

Roof span - the distance between the support points of the bearing beams. It determines the complexity of the future design. The higher this parameter is, the more difficult it is to build a reliable structure. If this value exceeds 6 meters, then the construction of the roof of the house should be done by professionals.

While the distance between the walls is less than 6 meters, you can use a wooden beam with a section of 10x15 cm or a metal beam, for example, an I-beam, as a beam. In this case, the distance between the structural elements must be chosen so that it is less than 1 meter.

For a heated room, the issue of roof insulation is far from idle, so we will also consider it below.

Reinforced concrete roof

An alternative to a wooden base and backfill with expanded clay is reinforced concrete. Oddly enough, this material is attractive enough to create a flat roof. In this case, most of the load falls on the I-beam load-bearing beams.

Do not create a roof frame with your own hands in this case. In fact, it will be, but somewhat not the same as in the case of wooden structures. Reinforced concrete slab involves the use of longitudinal and transverse reinforcement, which increase the resistance of concrete to bending and damage.

If the span of the roof is less than 5 meters, then beams with a height of up to 15 cm are used. The brand of concrete is no less important, since there are many of them and each is designed to perform certain operations. If the roof will not be used, except in rare cases of snow removal or repair, you can choose the M250 concrete brand, which can be ordered or prepared on site.

You can choose a method for producing concrete only after its volume has been calculated. If less than 5 m3 of mix is required, then you will need to work hard to find a company that delivers ready-mixed concrete in small concrete mixers. If there is no such organization in your city, you will have to do all the work yourself.

When you create a flat roof with your own hands from concrete, you need to order crushed stone, sand and cement, as well as ensure the supply of clean water. The solution can be prepared as you wish, but the most reliable method, involving the use of a concrete mixer. A recipe of this composition may vary depending on the brand of cement used, so we will not give it. For cement ПЦ 400, the quantitative ratio Щ: П: Ц: 8: 4: 3 is true. The water here is added in two parts.

Formwork is made of boards. They are laid out on the lower shelves of I-beams flush against each other, after which comes the turn of roofing material.The next stage of work is the installation of reinforcement, which should be both along and across the beams. It is best to use steel bars with a diameter of at least 10 mm. For the specified roof parameters, the pitch of the reinforcing mesh should be selected about 20 cm.

In the process of pouring concrete, the reinforcing elements can move, so they are securely fixed. A special steel wire is excellent for this purpose, but a welded joint can also be used.

Correct installation of a flat roof should be carried out with small pebbles placed under the lower parts of the reinforcing cage, which can be taken from the rubble that went into the preparation of concrete. This will allow the mixture to completely surround the steel bars, protecting them from possible corrosion.

Concrete pouring itself can be carried out in various ways, but in an ideal situation, the procedure should be performed continuously until the entire surface of the future roof is covered with a mixture. The stacked composition must be sealed, for which a vibrator is perfect. The use of rammers must be done carefully, since a home-made design at this stage does not have a very large margin of safety.

Concrete work is best done in dry and warm weather, because such a mixture does not like cold. Of course, you can order special concrete, which will feel good in any conditions, but it will cost more. Heat for concrete is less dangerous than cold, but also requires the implementation of certain measures aimed at protecting the composition. The difficulty in this case is that water evaporates from the concrete, which means that the process of cement hydration starts to slow down, which will lead to weakening of the material. To avoid this, the surface of the fill is covered with a plastic film, and in the case of extreme heat it is even moistened to compensate for the loss of water.

Roof insulation

The construction of the roof of the house is carried out with the implementation of mandatory thermal insulation, as this significantly reduces heat loss through the roof. A feature of this type of construction is that they can be insulated not only from the inside, but also from the outside. First of all, it is necessary to carry out external insulation, since the internal can be done already during the operation of the building.

Today almost everywhere refuse rigid thermal insulation boards, choosing mineral wool. Such heaters are characterized by low thermal conductivity and boast a very low weight. The second feature of this material is incombustibility, which was the reason for the increase in demand for it. It is still better to choose plates for the role of internal insulation. Expanded polystyrene copes well with this task. Its installation is made on wooden planks, which are located every 30-40 cm. The boards themselves are glued to the wood with mastic or special glue.

Final touch

The final stage of work involves the implementation of waterproofing. Here it is advisable to use a special roll material designed specifically for laying the top layer. Typically, these sheets have a special coating that protects against accidental damage and exposure to UV radiation.

The panels themselves are overlapped, and for the inner layers it is 7 cm, and for the outer 10 cm. These figures are given for those types of roofs, the slope of which is more than 5%.

Each new layer should be laid so that the lower seams are located closer to the middle of the sheets of rolled material. All strips must be laid in the same direction.

In the event that the panel is shifted during installation, it must be tried to return to place without peeling. If this operation fails, the problematic fragment is cut off and re-glued.Layers can be mounted in different ways, however, if it is planned to use mastic, the time interval between laying adjacent layers should be at least 12 hours.

Above, we examined several ways in which a flat roof can be created with your own hands. They are quite simple, so they can be taken into service even by a lay person, however, you need to remember that when performing such work it is better to get professional advice, since he will see those mistakes that you ignored.

Alas, no comments yet. Be the first!