Copper has established itself as a roofing material in the Middle Ages. For example, a cathedral built in Lower Saxony, whose roof was erected more than seven centuries ago, is an excellent example of the durability of copper. Of course, in the case of the cathedral, the roof underwent many repairs, but in an ideal situation, the service life of copper can exceed 100 years. High-quality material will last a very long time, but the installation of the copper seam roof was also important. This article is devoted to our article.

Content

Entertaining chemistry

The color of copper changes during the operation of the roof. Dark red turns into brown over several years, and then the material is covered with a dark oxide film. As a rule, this will take up to 6 years. After a couple of decades, a film of copper carbonate or its chloride forms, which have a beautiful red or malachite-green hue. The coating that occurs on the surface of the sheets of roofing material is called patina. It is it that ensures a long service life of copper, since it protects the metal from further oxidation, acting as a kind of buffer.

When the result is needed immediately after completion of work, it is better to purchase sheets of copper that have been artificially aged using special chemical compounds. Such material is also called patinated copper.

Copper should be ordered in rolls. Their width is from 60 to 70 cm, and the thickness can vary from 0.6 to 0.8 mm.

Preparation of the base and rafters

The base for the copper roof must be reliable and durable. Copper is flexible and very thin, so any problem with the rafters or skew will damage the roof covering. This must be remembered when installing the copper roof. The wood must be of high quality. In this case, its properties as a case play a decisive role, because it makes no sense to use a coating that will last more than a century with an untreated tree, whose service life is at best a couple of tens of years.

To create a "skeleton" of the roof, durable beams are selected, treated with an antiseptic composition. Horizontally on top of the rafters, a roll of waterproofing material unfolds. It is laid so that there is a slight overlap. Usually, a diffusion membrane is chosen for this role, which protects the heat-insulating material from water, and also drains condensate from the cornice. Between themselves, the strips of material are fastened with a double-sided construction tape, and the material itself is spread with a slight stretch to prevent it from sagging.

The base for the folded roof should be solid, so it should be made from boards impregnated with an antiseptic. The latter requirement is mandatory, since only special impregnation can guarantee high protection against biological damage and rot on load-bearing structures. In a continuous flooring, openings are usually left for a chimney, dormers and roof exits, after which a second layer of waterproofing is laid on the base and you can proceed to the "copper" work.

The thickness of the flooring under the rebated roof should be calculated, since it is necessary to take into account not only the own weight and mass of the copper sheet, but also the wind load, which can be large. In this case, the distance between the rafters is also taken into account.

Copper paintings

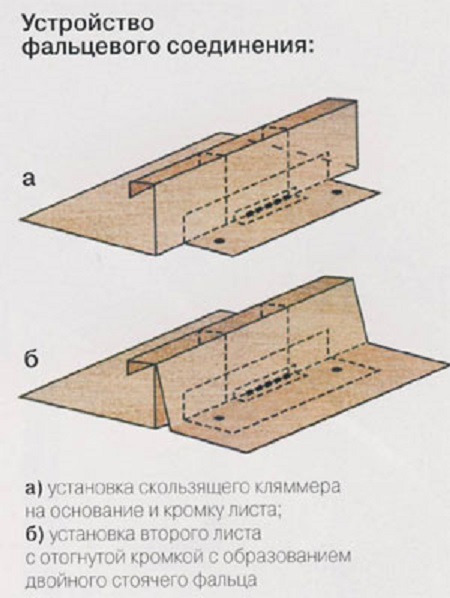

The installation of a copper roof is carried out using elements such as paintings.These are special blanks representing a long copper fragment having folds on the sides. There are two folds in this case - small and large. The height of the first of them is 25 mm, and the second is 35 mm. The paintings can be fixed using the double standing fold technique. In this case, the big fold is bent over the small one to get an L-shaped, and then the resulting compound is bent again. For such purposes, they use a special tool - a frame.

The height of the resulting fold is at least 23 mm. Such a connection should easily tolerate temperature differences and expansion caused by them, so it is necessary that there is a gap of more than 3 mm between the large and small folds. When using this type of fastening, nothing will interfere with the possible expansion of the sheets at the joints, which means that there will not be any bends and deformations of the roofing.

In this case, all the elements of the roofing are created directly at the construction site using mobile equipment. The rolling machine is used according to the markup that is already in place. This approach allows to obtain a more accurate cutting of sheet material than when this operation is performed at the factory.

Since they try to avoid transverse seams, the pictures are slightly longer than the ramp. This increases the tightness of the roof and even reduces the consumption of material. Another advantage of making copper paintings in place is that the risk of damage to them is minimal, while in other cases defects can appear already during transportation. For valleys and ridges, workpieces are made on workbenches, after which they are connected to the roof and fixed.

It is better to purchase ready-made elements of the drainage system. They are made at the factory, and in place you just need to mount it correctly. In addition to gutters and pipes, special nets are used - spiders. They are installed in sewage funnels and prevent leaves and other debris from entering them.

Subtleties of installation

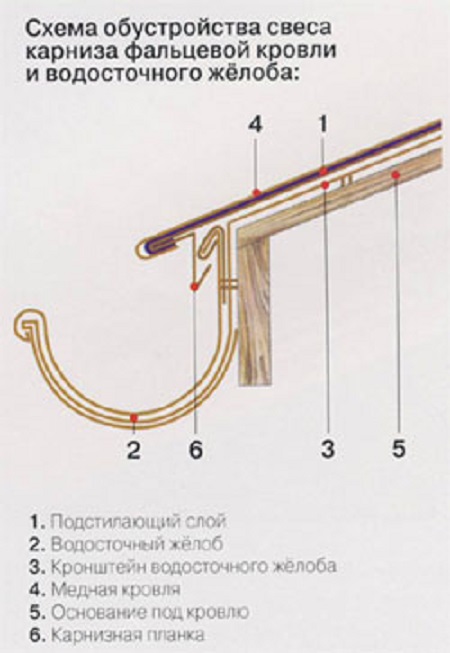

Installation of a copper roof always begins with eaves overhangs, after the arrangement of which they are already moving on to other work. A ventilation mesh is installed to close the ventilation gap of the counter-grill and protect the under-roof space from birds and insects. Then, the recesses in the base are made on the cornice. Only a 5 mm recess is enough to mount the brackets under the drain. The gutters are connected using special docking elements, and their slope is selected within 3..4 mm per 1 meter. This is necessary to ensure a normal flow of water, and a similar slope is achieved by bending the mounts at different levels.

After the work with the drainage system is over, they begin to install the apron. A curtain rail connects the gutter to the roof covering. Each such element is wound onto a slope of 15 cm, after which it is fixed with nails to a wooden base, and its lower part is in the gutter. In this case, all precipitation will only drain into the drain, and not past it.

In the event that there are valleys on the roof, they are performed before laying the paintings. There are only two options for installing such elements. In the first case, a simple structure is used that has a bend under the picture, and in the second, a special valley with a strap. The picture is hooked to a bar and a practically tight connection is obtained. The second method is usually applied on roofs, where the slope of the slopes is more than 15 degrees. If there are wide chimneys, then behind their upper part they make a banding. This is a small gable structure that does not allow precipitation to accumulate above the pipe, forming a puddle or snow drift.

Before you begin installing the seam roof made of copper, mark the plane of the base, after which the first picture is laid.It should go 3 cm beyond the border of the apron. The protruding part is bent over the apron.

Laying of copper paintings can begin both from the corner and from the center of the roof, but the second option is more preferable, because it allows you to arrange the seams so that they are symmetrical.

The paintings are fixed with the help of special clamps - clamps. These are brackets made of copper, which are fixed with special copper nails to a wooden base. Klyammery provide fixing of a leaf in the necessary position. They are inserted into a standing seam, after which the paintings are joined together, which allows you to completely hide the place of attachment. On the main surfaces of the roof, it is recommended to use at least 4 staples per 1 m2. The areas located along the perimeter of the building are already fixed by 5 staples per m2, and the step between the clamps is reduced to 35 cm.

Klyammery are of two types - rigid and mobile. It is advisable to combine these types of fasteners, because otherwise the roof surface may swell due to thermal deformations that are associated with seasonal temperature changes. The final stage of installation of the roof is the processing of gables, ridges, skates and junctions.

It is best to use a ventilated ridge, since one of the problems with installing a copper roof is ventilation, which should have good traction.

Where is copper sheet used?

Experts recommend installing a copper roof when the angle of inclination of the slopes is at least 16 degrees. It is suitable for both conventional roofs and complex structures.

Since the service life of the copper roof is very long, special attention must be paid to the ventilation of the subroofing space. Otherwise, after a few years, mold or fungus will take root here. Although the antiseptic coating provides good protection for wood, it’s not worth the risk.

Copper itself, as well as flexible tiles, allows you to create a sealed roofing carpet, which is why ventilation is important, because the air will not be able to exit only through special openings. In the absence of ventilation, condensate often accumulates, so without using vents, under the roof surface there will be a real swamp.

The service life of copper is very long, but you need to remember that this is the situation only when the roof is operated correctly. The following situation can be cited as an example. If a piece of film, a twig or foliage lies on the surface of a copper sheet, then sooner or later corrosion will begin. This is the reason why copper gutters are cleaned at least once a year.

If the roof of your house is made of copper, then it is undesirable to allow it to contact with other materials or alloys. The one exception is stainless steel, which does not interact with copper in any way. It is worth saying that all additional elements should be made of copper, otherwise corrosion will begin, and the roof will need to be urgently repaired.

To summarize, we note that the installation of a copper roof in the manner described in the article is the most optimal, since it has proven itself well and does not require special equipment. Of course, such work should be carried out by a team of professional roofers, since a beginner can make so many mistakes that the roof will survive at best a couple of winters.

Alas, no comments yet. Be the first!