When it comes to such a thing as a filly, the roof with it is mounted using eaves overhangs covered with boxes. With the help of fillies, they are lengthened. This article will talk about this important roofing element and how the eaves are closed.

A filly is a piece of plank used to lengthen the rafters used in the construction of roof overhangs. The need for it arises when the length of the board used for the manufacture of rafters is less than necessary for the device overhang. Without it, it is practically impossible to divert water from the roof from the walls. If this is not done, then it will rain in the form of rain or thawed snow directly on the walls, which will be constantly wet. To prevent such an unpleasant situation from the walls, indent the size of at least 40 centimeters.

The board from which the filly is made is usually smaller in width than the width of the rafters. For example, if the rafters are made of boards with a size of 150x50 mm, then for the manufacture of fillies you can use a board with a cross section of 100x50 mm.

The use of filly in the installation process for the construction of the roof and its rafter system makes it possible:

- in their manufacture apply lumber with a shorter board length;

- to facilitate the lifting and installation of rafters on the Mauerlat, as they will have less weight;

- with less effort, draw a line of overhang of the eaves, while using the filly lighter than rafters;

- in case the filly is damaged or rotting, it can be replaced painlessly without dismantling the roof structure.

In our time, as in the past, there are craftsmen who can make carved filly, the roof with which takes on a truly attractive look. A house with such a decorative element is unique and original.

The device of eaves overhangs without filly

If you make a box under the cornice or make a wooden frame, then this will be a great opportunity to refine the appearance of the building. All this will make it possible to close all kinds of protruding elements of the roof structure, to which you can classify the crate and rafters. How the various elements of the cornice will be hemmed will depend on the type of cornice box made.

The most effective and simplest method of manufacturing such a box is the installation of the frame using a frontal or wind bar and hem. They are placed on the lower (inner) part of the rafters.

When using this method, the tastes of the owner of the building can be taken into account, since there are two options for trimming the ends of the rafters. They can be cut vertically so that the butt will be parallel to the wall. In another case, the ends of the rafters can be cut perpendicular to the rafter axis.

Let us dwell in more detail on the option with parallel trimming of the rafter ends (with this method, the filly is not an element of the roof structure):

- Performance of work will require the use of rafters, as well as a retractable ladder. For fastening roofing elements you will need a screwdriver and wood screws;

- First of all, it is necessary to attach a wind board, then the outer hem and inner (wall) boards are sequentially attached. All boards have the same section of 150x20 mm;

- In the manufacture of the box selected not twisted and even boards are used. They should be cleaned of bark and not have a large number of knots.When the manufacture of the box is planned to be done as a “hem”, without the use of finishing materials, the work is performed using calibrated dry boards having a cross section of 50x20 mm.

- After the front crate and rafters were closed, for the purpose of protection, the box is treated with special solutions. If you want, then the box can be treated with stain or varnish. In this case, “filing” will last longer and most effectively.

You can achieve the highest quality coverage using a fairly expensive, but truly effective shipborne varnish.

- As a box closing material, C10 grade flooring is used, having white or light gray color. Vinyl siding can also be used, which is easy to install and lightweight.

- Some parts of the cornice can be hemmed using a special material - spotlights. It is a perforated plate made of aluminum or plastic. Although their cost is considered quite high, it is justified due to the attractive appearance of the material and its high functionality.

- Regardless of the material that was used to file the cornice strips, the frontal (wind) sides of the box must be closed using external corners, the color of which must match the color of the box itself. The size of the corners should be 50 mm, their obortovka in size should correspond to the width of the wind.

- In order to refine the sides of the box, lids are cut. This is done manually, and the material is smooth sheets, the shape of which will depend on the shape of the end of the boxes.

- Performing front hemming is much easier. This is done using two boards with a cross section of 150x20 mm, which are attached to a protruding crate. They are subsequently sutured with the most suitable material.

The device of eaves overhangs with the use of filly

When a horizontal filly is used to hem the cornices, the roof, the features of which may differ from each other, is mounted with some additional difficulties and requires a lot of labor.

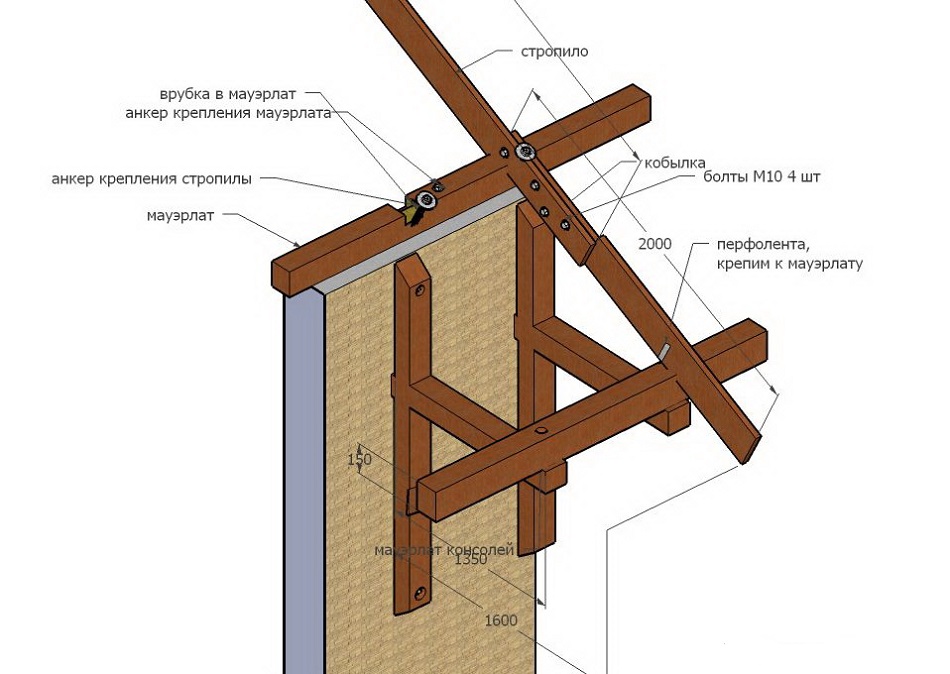

As a structural element, the filly is nothing more than a board with a section of 100x30 or 150x30 mm. In this capacity, trimming of rafters can act. Their fastening to the rafters is carried out in such a way that the arrangement of wide planes is perpendicular to the wall.

Carrying out the installation of fillies, it would be right to take brickwork as a landmark or to do work using a level.

After installing the filly, they begin the process of attaching the hemming boards. As a result, a box with a lower plane located horizontally is obtained. In the future, the box can be decorated or decorated depending on the general architecture of the adjustment and personal tastes of homeowners.

Getting to the installation of the cornice, one should not forget about such an important point as the ability of the roof to “breathe”. This implies that warm air should enter the sub-cornice section. Passing through roof elements such as rafters, lathing and roofing, he rushes out. Thanks to the air flow, effective ventilation takes place, which creates the conditions for the dry state of the roof and extends its service life.

Based on the foregoing, it is very important to prevent any ridge element or cornice element from becoming leakproof. For this reason, when performing installation work, do not use foam and silicone. The exception is only pipes. Otherwise, after several years of operation, undesirable processes associated with decay of the roof structure may begin.

Currently, cornices are hemmed in a variety of ways. When there is a filly, the roof can be trimmed with a regular triangular cornice.It is easy to install and, in comparison with other remote cornices, eliminates such an undesirable moment as an unpleasant buzz during winter blizzard winds.

Let us dwell on the basic rules for the construction of a triangular cornice:

- Trimming rafters must be done flush with the external walls. In this case, it is not allowed that the cornice hangs over the wall. If it still hangs, at the junction of the rafters and the walls, a cornice board equipped with a drain is nailed.

- The formation of the cornice removal occurs as a result of an increase in the length of the rafters with the help of filly. They are nailed directly to the rafters. The fact that this method has gained great popularity is due to the advantages that it has. For example, it is guaranteed to protect the cornice space from raindrops, which can blow a strong wind there. All this is achieved with the help of a simple device called "filly." The roof, the size of the gap with which the filly form, should be provided with good ventilation of the space under the roof.

- The removal of the cornice, where the filly is located, remains open from below. It can be closed using planed and planed hemmed boards of equal width. Their thickness should be within 25 millimeters (hemming cornice). The roof space should be covered with boards perpendicular to the wall and from below. The wall and boards for ventilation of the roof also have a gap between them.

- The cornice extension is strengthened by means of consoles equipped with metal or reinforced concrete anchors. They are embedded in the wall. In such places, the filly is closed flush with the console. The use of this method is justified when the hemming cornice is carried out at a distance that is higher than the allowable for the filly of wood.

- Brick overhang is done on the stone walls of the houses, the upper part of which is made of bricks. In this case, a gradual allowance of the rows is observed by an amount that does not exceed a third of the length of the brick (80 mm). Eaves brick overhang should not be more than half the thickness of the wall.

The long-term operation of the roof is largely determined by the quality of the eaves. During their installation, a significant role is given to such a structural element as a filly. The roof, the features of the work of which require competent execution of the cornice, may, otherwise, get wet or lose its properties due to wet insulation.

To ensure the durability and economy of the operation of the facade and roof, a set of measures is being developed that go beyond the scope of installation and supply of materials. The issue of creating a quality roof must be approached comprehensively.

The eaves overhang is a visual border that separates the roof from the external facade. It takes not itself an architectural accent and is a clear and obvious element of the building. For this reason, the process of designing a cornice should be approached with special attention, since it is one of the most critical building elements. Due to natural heat loss, ice can form on the eaves overhang. As a result, the cornice may collapse or clogging of the under-roof ventilation of the eaves may occur. The consequences can be very sad - condensation will form, mold will appear, the roof structure will begin to rot, etc.

When it comes to filing the cornice, this refers to the work associated with the installation of decorative elements on the lower plane of the eaves overhangs. Decorative decoration using siding, wood, copper and other materials does not belong to the most important stage in the process of designing an eaves overhang.

Prior to its formation, design and installation work is carried out on the bearing structure of the cornice and the components of the roofing cake.

Design and installation work on the eaves overhang device take into account the following:

- The magnitude of the departure of the eaves overhang from the support in the form of a bearing wall. It is the design value, depending on the bearing capacity of the structure and other factors that are taken into account when developing the project.

- Does the eaves overhang provide sufficient air in the subroofing space?

- The methods of attaching decorative elements in the form of panels should be such that they ensure their reliable operation in any weather.

Alas, no comments yet. Be the first!