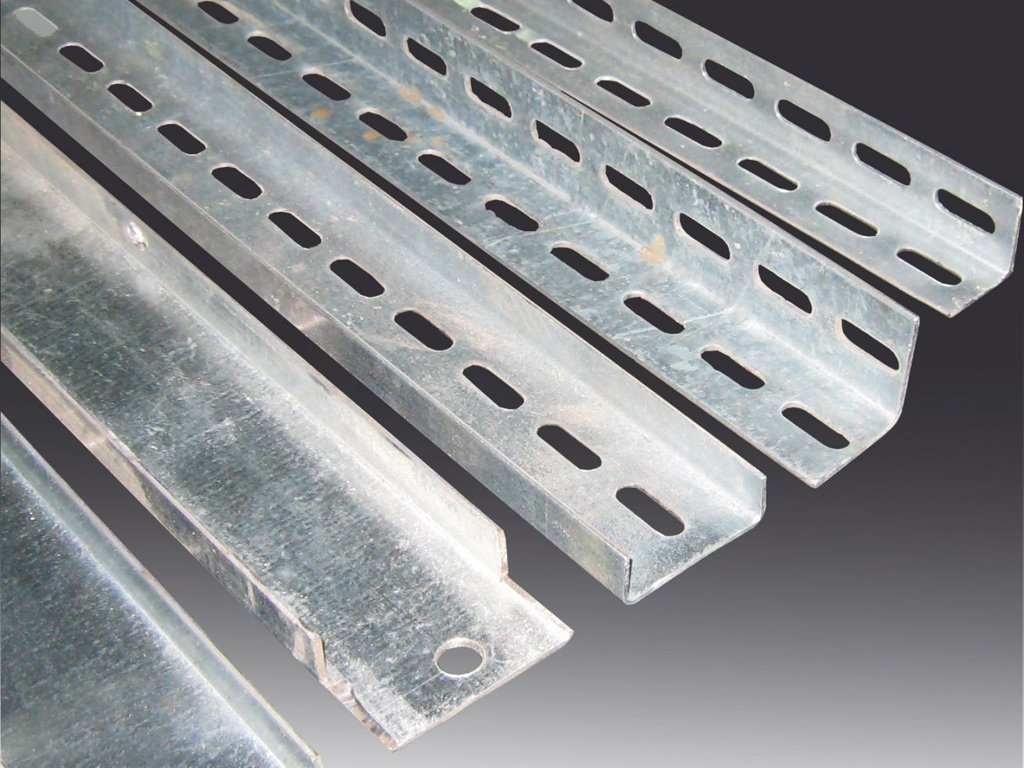

A variety of steel structures today are quite common in construction, but one of the simplest forms are channels. This is an ideal solution for many tasks, but sometimes a special variety of such products is used. The channel is perforated, the technical characteristics of which do not allow it to work with heavy loads, is used in the installation of various communications.

A perforated profile can be used for mounting various structures, but in most cases, the installation speed only increases from this. The main difference of such products is that they do not require any work preceding the installation of fasteners, because the holes are made at the factory.

Everything related to engineering networks in one way or another can be mounted using perforated profiles. It should also be noted that, unlike conventional cable trays, cable profiles are thicker, which means they can cope with a higher load. A perforated channel, corner or other type of such metal structures can also be used to install trays (we are talking about relatively narrow options that are used as a supporting frame).

As another area where perforated products are used, various finishing works can be mentioned. Usually this is the decoration of the interior, however, in the open air there are structures, the manufacture of which the channel went to allow it to work in a variety of conditions.

Content

What is a perforated channel

This is a kind of bent profile, which is characterized by the presence of holes. The perforation itself is designed to attach a metal structure to the wall. Galvanized steel is usually used, because the installation of utilities can be carried out in a variety of conditions. The protective layer in this case protects the steel from oxidation, which means it increases its service life.

Sometimes a different type of metal structure is used: a perforated channel, the technical characteristics of which allow it to work even in conditions of high humidity. In this case, another type of protection is applied - coating the surface of the paintwork.

Of greatest interest for protecting metal from corrosion are powder paints. These are solid compositions that include special resins, hardeners and pigments. The task of the resins is to create a surface film, and fillers and special targeted additives take on additional functions.

Various unscrupulous manufacturers may use unsuitable paints, so you get a perforated channel, the technical characteristics of which are very far from declared, which means that its service life will be short.

Powder coatings fall into two broad categories. The first of them acts through the use of thermoplastic film formers that form coatings without any chemical transformations. In this case, particles are fused and then the melts are cooled. The disadvantage of this technology is that the resulting film is soluble and thermoplastic, so it is not the best option for those cases when it is necessary to process metal working in difficult conditions.

The second category is what you need, since such powder paints allow you to get a perforated channel, the technical characteristics of which are ideal for use even in an environment with high humidity. These are thermosetting compounds based on a thermosetting film former. The formation of the coating occurs due to the fusion of particles and a number of chemical reactions accompanying this process.

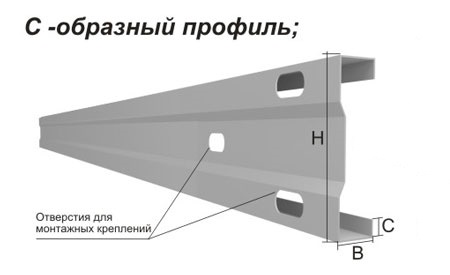

What is a C-shaped profile

One of the varieties of perforated channel is a special C-shaped profile. This is a perforated channel, the technical characteristics of which have not changed much, and the main difference is the curved walls. They allow the use of channel nuts. This solution is ideal for various installation works and boasts a number of important advantages:

- 40% increase in installation speed.

- Increased bearing capacity through the use of an optimal combination of thickness and size of the holes while maintaining weight. A perforated channel, the weight of 1 meter of which is much lower than the standard one, is often used where high strength and a relatively small mass of structures are required.

The channel nut is a special fastener designed for use with C-profiles. This method of fastening is ideal, durable and does not require drilling or welding, because the perforated channel, the technical characteristics of which we are now describing, already has perforation.

- The versatility of this method. It is suitable for installing trays, and as a support for water pipes, and can be used in the installation of various ducts.

- No weld work is required since the nuts allow for very quick installation or repair.

- Through the use of curved edges of the walls, it becomes possible to perform two-sided installation, which significantly reduces the consumption of materials.

- Changes to the finished design are made extremely simple and quick, since welded joints are not used here.

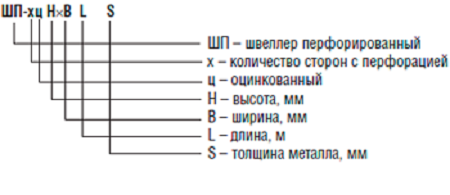

Channel designation perforated

If you need to purchase such products, then you need to know how to choose the right ones. For simplicity, a special designation is used, which will tell the specialist about the form, design features and other features.

As an example, consider the ShPC-2 40x70 L = 2000 S = 2. The first letters represent the abbreviation: ШП - the channel is perforated, and “c” indicates the presence of a zinc coating. The first digit in the designation is the number of sides along which the perforation is going. In this case, two, but it can be three or one. The following numbers 40x80 is the ratio of the width and height of the metal profile. If you need a perforated channel, the technical characteristics of which allow it to withstand a fairly large load, then you need to pay attention to the last digit. This is the thickness of the metal, which affects the strength of the future design. Obviously, L = 2000 is a length, and it is expressed in millimeters.

This may complete the consideration of the features of such products. In the event that you need a perforated channel, the technical characteristics of which should allow you to solve a specific problem, then our article should help determine the choice of this product.

Alas, no comments yet. Be the first!