In the modern world there are many building materials for every taste and budget. Each consumer can choose from them suitable, based on their own needs and preferences. But invariably, for a long time, the wooden tee and its metal counterparts (for example, aluminum tee) are especially popular. It is worth understanding what the secret lies.

Content

Key Features of I-Beams

The variety of I-beams is not as large as that of some other materials, but still there are basic parameters by which to select the desired number of this profile:

- size and area of an I-section;

- weight of one running meter;

- the axial moment of resistance of the I-beam relative to the main axes;

- axial moment of inertia of the I-beam;

This indicator is more than a week for other beams of rectangular, square shape, which will increase the overall resistance of the structure to bending loads.

- static moment of inertia of an I-beam;

- radius of inertia.

These characteristics can be found in the reference tables. In addition, there are special formulas and programs for calculations.

Permitted loads on wooden I-beams: lateral force max 11.0 kN / m; bending moment max 5.0 kN / m (in accordance with GOST 20850).

It is strictly forbidden to drop the beams when loading / transporting / unloading.

Transportation of wooden I-beams should be carried out only in covered vehicles or by rail. So the material will be provided with the necessary protection.

Storage conditions for wooden beams

First, the beams must be sorted by size. Secondly, sagging and permanent deformation should be avoided during storage. To do this, I-beams must be placed on wooden gaskets in stacks. Thirdly, one should shelter the material from precipitation or store it indoors, since the tree is not resistant to adverse external influences.

I-beam Benefits

An I-beam is an H-shaped profile made of metal or wood. It is used to strengthen structures when creating formwork; It is necessary for floors, walls.

Most often, I-beam wooden beams are used in the construction of frame houses. This material provides the following benefits:

- high specific strength of the whole structure, durability due to the stiffener made of multilayer veneer or OSB boards;

- universality in application;

- unlike similar materials, an I-beam with proper installation will never creak;

- lack of shrinkage, drying, shifts and cracks in the structure (again, subject to all installation conditions);

- a relatively small weight of the floors, which will greatly simplify installation and extend the life of the unit;

- reduction in the cost of the foundation.

Production of metal I-beams

There are two main methods for the production of metal beams: welded double tee and hot rolled. Welded is made by welding. This method is used to obtain beams with dimensions of 60 mm or more. Hot rolled is produced from steel billets by hot rolling (beams with a size of up to 60 mm).

The advantages of a material such as a welded tee:

- a 10% reduction in the mass of the structure (when compared with a hot-rolled I-beam) due to the optimal selection of the composite beam section;

- the possibility of using various types of metal shelves, walls in the beam section;

- the possibility of producing asymmetric sections;

- waste minimization.

The main stages of manufacturing an I-beam:

- Cut the pin.

- Editing a stamp.

- Beam assembly.

Which I-beam to choose: wooden or metal?

Wooden beams are often a more economical option. They are easy to manufacture and install, have low thermal conductivity than steel or reinforced concrete.

Cons of the tree: relatively lower mechanical strength (which means that beams with a large cross section will be needed); low fire resistance; the possibility of damage by microorganisms and damage to the material by insects (careful treatment with flame retardants and antiseptic drugs is required).

I-beam metal has a whole list of advantages, but it is quite expensive. Firstly, large beams with a serious load can be covered with metal beams. Secondly, steel does not burn, is resistant to biological damage.

In case of fire, metal beams will begin to melt and bend. Therefore, they need to be covered with thermal insulation and basalt plates.

There is a slight drawback: the metal can become corroded. But this is easy to cope with, you just have to use protective coatings, which are plentiful on sale.

Which of the materials is best to choose is up to you. Carefully analyze the above advantages and disadvantages of both, because you have been building your house for more than one year. Among other things, you can pay attention to the reinforced concrete double tee. He is also very good and reliable.

Read more about some varieties of the I-beam

Aluminum tee has a high degree of strength, usually made of alloys AD31 (for building houses) or 1915 (high strength). It is worth stopping the choice on it, if you have a goal to build the most lightweight design. Among other things, aluminum is environmentally friendly and corrosion resistant.

By the location of the shelves, there are two subspecies of aluminum I-beams: with parallel faces and with a slope of the faces.

The length of the beam: I-beams with measured length, with multiple measured length and unmeasured length. The length of the aluminum beam is usually in the range from 1 to 6.7 pm

By the accuracy of production, the aluminum tee is made conventional, high and high accuracy (depending on the application).

According to the state of the material, there are beams: not subjected to heat treatment; annealed (M); hardened, aged naturally or artificially (T, T1); completely hardened, aged naturally or artificially (T4, T5).

The main types of coating used: anodized (An); liquid paint (Zhl); liquid electrophoresis (Zhe); polymer powder (P); two-layer complex (K).

There is also a classification according to the conditions of use: normal (B); columned (K); broad-shelled (W); necessary for the construction of suspension tracks (M) and for the reinforcement of mine shafts (C).

I-beam— metal construction having a large thickness of the shelves, so that it can be used as a supporting element of the building. It is produced from steel by rolling. Such columns are most often put into spans of considerable size and at high crane loads. This type of beams is very popular, as it has high strength, but in some cases it is advisable to replace it with a wide-shelf one. Compared to other I-beams, the I-beam is the heaviest and most wear-resistant.

A wide-shelf I-beam is a supporting beam structure with a metal profile, long sides of the shelves that are parallel to each other, and a section. Based on the number of spans in the building, the following wide-flange beams are used:

- split. They are mounted on one span.It has light weight, the ratio of height and width 1: 1;

- continuous. Accordingly, they are mounted on several spans at once. Height and width are correlated as 1: 2.5 - 1: 1.16.

The increased width of the shelves guarantees increased stability of this type of I-beam. That is why, it can be mounted as an independent element that does not require additional details. This helps reduce the amount of work required as well as reduce costs.

Channel I-beam is a U-shaped steel product. It is made of sheet metal, used to give stability and structural strength.

Based on the requirements of GOST, the maximum deviation of the width (height) should not be more than 3 mm, the maximum deviation of the length of 100 mm. Curvature - not more than 0.2% of its length, the maximum deviation in the mass of 6%.

Channel I-beam allows you to strengthen the supporting structure, floor, thanks to the ability to work on bending. Now there is a huge assortment of channel sizes for various fields of application.

This material is more in demand in the construction of buildings where the assembly of solid frames, the installation of floors, reinforcing walls is necessary.

To summarize a short summary. The main advantages of aluminum I-beams:

- high rigidity, excellent strength with relatively low weight. Just due to rigidity, these products are much stronger than analogues. For example, based on calculations, a square profile with the same cross section is seven times weaker.

- a symmetrical section is the most advantageous type of section, since the bending load is best distributed over it.

- durability, stability. The application of a variety of anti-corrosion coatings contributes to maintaining the quality of the aluminum I-beam for many years. It is able to withstand both low and high temperatures, resistant to mechanical influences of the environment.

Calculation of floor beams

When calculating the cross section of a wooden beam, the dead weight of the structure must be taken into account (approximately 190-220 kg / m2), operational (temporary) load (200 kg / m2) Floor beams are laid over a short span. The desired step of mounting the I-beam is equal to the step of installing the frame racks.

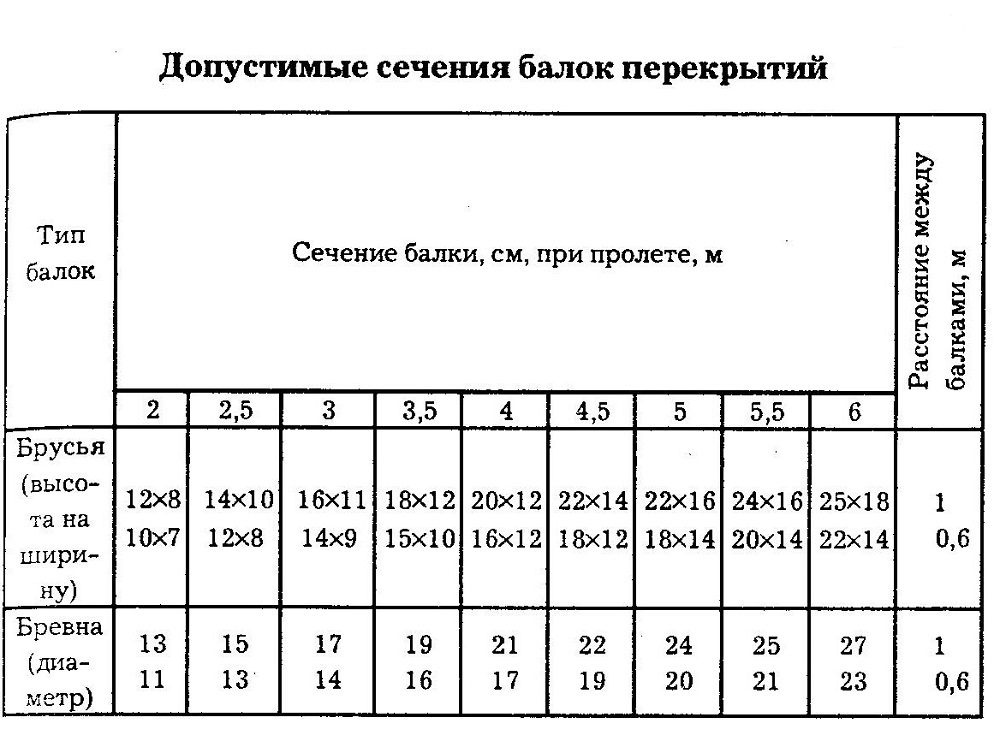

In order to calculate the minimum and optimal cross-section of wooden floors, you can use special programs and tables.

In case of independent construction, in the calculations it should be taken into account that the metal beam has hinged supports (the ends are not fixed). The load on the floors with a steel I-beam, taking into account its own weight, should be calculated 350 (without screed) - 500 (with screed) kg / m2.

The optimal pitch between I-beam steel beams is 1 meter. To save money, you can increase the pitch to 1.2 m, but not more, otherwise the design will lose its rigidity and strength. You can find a table that will help in choosing the number of beams at various steps and length of run.

When using reinforced concrete beams, do not forget about the following basic rules:

- the height of the beam should be more than 1/20 of the length of the opening;

- beam width should be correlated with its length as 5: 7;

- beam reinforcement should be carried out using 4 bars of reinforcement d12-14 mm (at least), two from the top and bottom;

- concreting should be without interruption, so that previous portions of the solution do not have time to seize before laying the next.

It is not so simple to make the correct calculation of I-beams for construction, even with specialized programs. Therefore, if you are new to this business, do not take risks, but rather contact qualified specialists. They will help in the calculation, as well as explain all the intricacies of the use of the I-beam. I wish you success in a difficult, but such a pleasant business as building your own home.

Alas, no comments yet. Be the first!