Since childhood, we all loved to look at the sky, during the day - at floating clouds, and at night - at alluring stars. The view of clouds and stars calms, brings the soul into balance, and simply improves mood. Now imagine that you are lying at home, on your favorite sofa, and admire not the boring ceiling, but the sky above your head.

Only a transparent roof of your house can give you such a fairy tale. It gives natural light in sunny weather, makes the space open and airy, and modern materials allow you to create a light and, importantly, durable roof of any configuration.

Content

Transparent roofing, main types and application

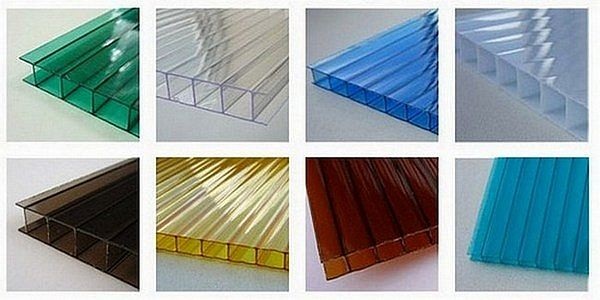

A whole range of the latest materials for coating and creating a transparent roof are presented on the modern market. Among them, polycarbonate (both monolithic and cellular) stands out for its excellent qualities. Plexiglas, as well as PVC sheets (“transparent slate”) have been widely used. Roofs made of expensive materials are much less common: cellular plexiglass and corrugated cellular polycarbonate.

A translucent roof is an aluminum profile filled with a transparent material, such as acrylic honeycomb glass. The shape of a transparent roof can be very different: in the form of arches or inclined slopes, as well as domes and pyramids, different polygons and many other figures.

A transparent roof finds its application for various purposes:

- arrangement of a winter garden, porch or greenhouse;

- pool creation;

- organization of a home observatory;

- connecting galleries of several buildings.

An important role in creating a project is played by the climatic conditions of the region, which will significantly affect not only the strength characteristics of the entire structure, but also the organization of overhead lighting.

Translucent roofing, the main advantages

Firstly, a transparent roof fills the room with natural light and visually increases the space.

Secondly, not only decorates, but also protects from the weather.

Thirdly, it does not cause much trouble when using.

The translucent roof is also waterproof, durable, resistant to temperature extremes, as well as to the effects of chemicals and ultraviolet rays.

Translucent roofs are widely used in suburban construction. They are much lighter than glass coatings and are not subject to corrosion.

Translucent roof, installation features

The light weight of such a transparent design makes the installation of the roof simple and requires conventional tools for processing wood and metal.

If you take into account the peculiarities of plastic and its ability to thermoform, it becomes clear that by heating it you can create the most incredible geometric elements and roofs, for example, a transparent roof terrace in the form of a dome.

To increase the thermal insulation properties of a transparent roof, some manufacturers recommend the use of plexiglass or monolithic polycarbonate; to improve heat and sound insulation it is best to use double-glazed windows or cellular polycarbonate.

A transparent roof is often made of polystyrene and polycarbonate without a protective layer, which leads to cloudiness after a while. The service life of such a coating is reduced to 2 years. These materials are best used only for interior elements requiring transparency.

Translucent roofing is simply intended for the use of cellular polycarbonate, which is also called cellular or channel. It is well suited to cover:

- patio, pool;

- visor or canopy;

- conservatory, greenhouse or greenhouse.

It can also be used:

- for vertical glazing;

- creating transparent lightweight partitions;

- when using anti-aircraft lamps.

Today, there are transparent panels in a variety of colors. They make translucent roofs light and elegant, while providing good sound insulation. This material is 12 times lighter than glass, and 200 times stronger !!!

The main disadvantage of cellular polycarbonate is a high rate of thermal expansion.

The panels are interconnected using special connecting profiles made of aluminum, steel or polycarbonate.

To increase the operational life of these panels, make sure that they do not come into contact with metal elements.

Do-it-yourself transparent polycarbonate roof

Next, we will consider one of the most common options for creating a translucent roof, for which cellular polycarbonate is used as a coating.

First, we establish the supporting structure for the roof. The main steps in creating a roof frame from transparent or translucent cellular polycarbonate will be as follows:

- first we create load-bearing structures and make them stiff and strong so that the roof frame is as reliable as possible;

- since your roof will be transparent, it means that we choose the supporting rafters not very thick (recommendation - 60 x 40 or 60 x 80 mm);

- when fixing the rafters, we take into account that the distance between their central axes would be 1.01 m, which dictates the width of the polycarbonate sheet;

- Further, profiles (connecting, end) are attached to the rafters, which must correspond to the dimensions and thickness of the polycarbonate plates, and you can buy them in the same place where polycarbonate is also sold;

- we fix the plate stops at a distance of 20 mm from the edge of the profile.

The minimum slope angle when installing the rafters should be 50 degrees, which corresponds to a length of 9 cm per 1 m of transparent roof construction. And the value of the optimal angle providing the required drainage should be 100 or more.

After installing the frame, we proceed to cover this structure with polycarbonate:

- to protect polycarbonate plates from the effects of reflected sunlight, we stick tape on their side surfaces;

- glue a strip of scotch tape on the upper faces of the sheets, on the lower side we paste a perforated version of the adhesive tape, which will prevent debris, dust, insects from entering the inner chambers;

- when using polycarbonate panels treated with a protective composition (from ultraviolet), they should be laid so that the marking is on top;

- paying attention to the gaps between the edges of the profile and the polycarbonate plate, we fix the polycarbonate plates in the grooves of the profiles (the gaps must be at least 5 mm to compensate for thermal expansion);

- after fixing the plates with profile fasteners, remove the protective film from the plates and install special plugs.

Next, we process only the joints of the roof with the supporting structures with silicone waterproofing mastic or sealant. With the correct performance of all previous works, the connections between the plates will not require sealing.

So, a transparent roof is a very attractive and attractive design solution. But in order to choose the right material to create a translucent roof, you need to take into account the functional purpose of the building under construction, the expected loads and the features of its design. Providing all the nuances, you can build your airy dream!

Alas, no comments yet. Be the first!