At the moment, soft roofing is one of the most popular materials in the world. It has other names - shingles, shingles, shingles, roofing tiles, shingle. It gained distribution due to its functionality and reliability. In this article we will talk about the distinctive characteristics of this material.

Content

General information about soft roofing

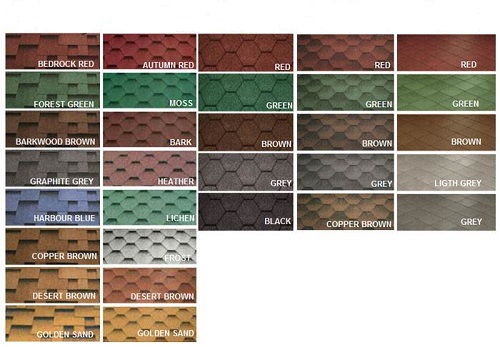

The soft roof has the appearance of small flat sheets with parameters of 1 x 0.33 m, as well as curly cuts from one edge. It is made with various forms (hexagon, rectangle, oval, triangle, wavy relief). In addition, it comes in various colors, which allows the use of a soft roof for any design decisions.

The production of flexible tiles, as well as other products, is regulated by SNiP. The soft roof falls under SNiP II-26-76 “Roofs” in the new edition. It regulates design standards, materials used, etc. In addition, you can see SNiP "Soft roof" 12-03-2001; SNiP 3.04.01-87 "Insulating and finishing coatings".

The basis of soft tiles is fiberglass well-saturated with bitumen or organic cellulose (felt). Using the base, two layers of oxidized modified bitumen are combined with a variety of polymer additives, providing the tile with excellent flexibility, but at the same time, strength and resistance to deformation.

The outer surface of the flexible tiles is covered with basalt granulate or mineral chips, due to which the material can be given various shades, as well as protected from adverse climatic conditions and UV radiation.

On the back side of the shingle, either an adhesive layer of special rubber bitumen is applied, which is closed with a plastic film (self-adhesive tile), or silicon sand (traditional tile). This is necessary so that the roof tiles do not stick together during transportation and storage.

Flexible roofing: structural layers of various types of tiles

Self-adhesive soft roofs are most often made in the form of a hexagon and has six layers:

- Basalt granulate or mineral chips.

- Bitumen enhanced with a special modifier.

- Fiberglass as a basis.

- Another layer of bitumen.

- Frost-resistant self-adhesive bitumen-polymer mass.

- Easily removable clear silicone coating.

The traditional soft roof is usually made in the form of a tile of a rectangular shape and has seven layers in its composition. The first four are exactly the same as in the previous case, and the rest are as follows: polymer protective strip; silicon sand; adhesive dotted strip of bitumen-polymer mass.

Flexible Roof Benefits

Flexible roofing has a lot of advantages. Imagine some of them:

- light weight. For transportation, you don’t need to hire a truck, the forces of a passenger car will be enough. In addition, this gives the installation additional conveniences: you will not need special tools and equipment to lift and lay the material;

- increased elasticity. Flexible tiles can be used for almost any roof construction;

- the service life is about 30 years, but with proper care it can last much longer;

- compact sheet sizes.Thanks to this, the roof from soft tiles is easily repaired (it is enough to dismantle one damaged element and change it to a new one);

- water tightness;

- soft roof serves as heat and sound insulation;

- resistance to decay, corrosion, rust;

- resistance to sudden changes in temperature;

- easy care. It is enough 1-2 times a year to carefully inspect the roof for damage, and if necessary, remove garbage and fallen leaves from it;

- profitability. It is achieved due to low waste, even with complex roofs.

Scope of a soft roof

Typically, a flexible roof is used to cover pitched roofs with a slope of at least 12 ° at a ratio of 1: 5. Soft roofing is used both for the creation of new and for the repair and reconstruction of old roofs (just lay it on top of the damaged old roofing, having previously prepared them for this). It looks great both on the roofs of private buildings, and on public and industrial buildings, especially if the roof profile is of complex configuration.

Soft roof: famous manufacturers and cost of material

In the domestic market, the following manufacturers represent the widest assortment: Finnish Katepol; Tegola (joint Italian-Russian production); American Certain Teed; Finnish Icopal; Technonikol (Russia) and others.

The cost depends on the manufacturer, model, as well as the color of the roof. In Russia, the construction market has a wide range of soft roofs in terms of price / quality ratio from economy to premium.

Soft roofing: mounting

Before installing a soft roof, it is necessary to build a flooring. For this purpose, you can use moisture-proof plywood, oriented chipboard (OSB-3), sheet piling and edging boards with a maximum humidity of not more than 20% (in the process they must be sorted by thickness).

If you opted for a trim board for lathing, the maximum possible gap between the blades should be no more than 5 mm. When carrying out installation work in the winter period, as well as using plywood or OSB-3 as a continuous flooring, you must save between the sheets 3 mm clearance to compensate for linear increase in the warm season. The edges of the plywood sheet are recommended to be strengthened with brushed nails or self-tapping screws.

To extend the life of the wooden elements of the rafter system, it is recommended to treat them with antiseptic substances and flame retardants, as well as provide ventilation, especially if there is an operated attic floor.

For good ventilation, there should be three elements in the roof: openings for the influx of fresh air, channels over the thermal insulation for its circulation and exhaust openings in the upper part of the roof.

The soft roof is laid at a certain step of the rafters, which depends on constant and variable loads, as well as on the configuration of the roof, and is in the range from 60 to 150 cm. The thickness of the used solid wood flooring depends on the step of the rafters.

Before mounting, be sure to remove the siliconized film from each sheet of flexible roof.

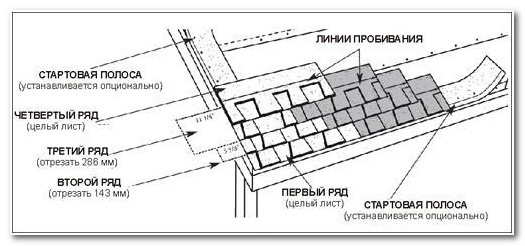

When laying a flexible roof, it is recommended to mark the slopes with chalk to prevent inconsistency of the coating layers. It is customary to lay the tiles from top to bottom, starting from the central part of the lower cornice towards the gables.

The first row of material is placed so that the lower border of the petals of the tile is 2-3 cm from the beginning of the cornice tile. The extreme plate of the tile, from which the laying of the second row begins, is trimmed by the amount needed to form the design pattern of the roof. The coating is cut so that it is flush with the edges of the gable cornice, and then glued with bitumen glue to a width of 1 cm.

Triangular slats are filled into the joints of the slopes with the walls, and a soft roof is already starting on them.A strip of a rug carpet is mounted on top. The upper part of the junctions is covered with metal aprons, which are securely fastened and sealed with bitumen mastic.

If the sections of existing brick pipes are more than 0.5 × 0.5 m and they are across the slopes, it is advisable to equip the grooves to prevent the accumulation of snow and water behind the pipe.

The ridge / eaves roof is divided into three parts according to the perforation zones and then overlaps (by 50 mm). The ridge tile should be placed with the short side along the slopes.

Some Provisions for Repairing Flexible Blood

Typically, repair work is divided into two types:

- Current when damage is less than 40% of the total roof area.

- Capital, respectively, when more than 40% of the roof area is damaged.

The main reason for leaking roofs covered with soft roll materials is the destruction of the bitumen layer, which is needed to provide waterproofing.

You can carry out repairs yourself if the building has small dimensions. First you have to identify the front of work, and for this, inspect the roof. If you find the following flaws, proceed with repair:

- visible pits and depressions on the surface in which water can linger;

- rotting of the material, the presence of moss in places where moisture is retained;

- bloating on the roof layer;

- mechanical damage, cracks;

After the procedure for inspecting the roof, you can come to the conclusion which type of repair will be needed. Based on the information received, an estimate is made.

Repair, like a soft roof device, must begin with the preparation of the base for the material to be laid.

If we talk about the current repair, it is possible to perform a partial replacement (patch) and repair on the old cover (1 or 2 layers of a new coating are laid on top). Putting latki, in these places they remove all the defects of the roof (cut down, pierce). After the surface is cleaned of debris and dust and poured with mastic (sealant). Top with a ruberoid or other rolled material. In terms of parameters, it should slightly exceed the dimensions of the surface subjected to repair. The edges are gently smeared with bitumen mastic.

But the above method is not always effective, so most often I put a couple of layers of a new one on top of the old coating. But, it is worth considering that at the same time the load on the rafter system is significantly increased.

Do not lay more than eight layers of material on the roof.

If the above methods do not help, then you need to start the overhaul. In fact, this is the installation of the roof again, and we already described it in the previous paragraph.

As you noticed, soft roofing is a very convenient and practical material, moreover, at an affordable price. Selecting it will not have to regret it. The main thing is not to forget about the regular inspection of the roof (at least once every two years), because it is easier to eliminate minor defects than to redo everything. And finally, advice: carry out installation of a flexible roof in the warm season to avoid problems with depressurization and damage to the coating.

Alas, no comments yet. Be the first!