The roof is an important part of the building. The reliability of the shelter depends on it. Today there is a huge selection of a wide variety of roofing materials. The most profitable option today is a built-up roof. What is it?

This type of roofing material has what everyone who prefers to save usually likes. In this case, anyone can install the coating. This does not require any special skills. The roof of surfaced materials is also very reliable and durable. Despite its availability, it is used almost always only for flat roofs. And this is the most important drawback of such a roof.

Content

Where are soft surfaced materials used?

There are several ways to use a similar roof:

- Firstly, for laying the roof of various structures and buildings;

- Secondly, a soft built-up roof is used to waterproof the foundation or even the bridge;

- Thirdly, for the construction of underground structures, including tunnels and garages;

- Finally, these materials can even be used to arrange water channels and pools.

The built-up roof is used in any climatic conditions. Especially often it is used in areas where the climate is very harsh.

Surfaced roof types

This subspecies today applies to roll roofing. According to GOST, it can be classified according to several criteria. So, according to the structure of the canvas, a soft built-up roof is:

- Mono-basic;

- Baseless.

By the type of basis, it is divided:

- Fiberglass;

- Cardboard;

- Polymer;

- Asbestos;

- Combined.

Depending on the protective layer of the built-up type roof there are:

- Sprinkled with;

- With a film;

- Or with foil.

There is another classification of the material according to the component of the coating composition. It:

- Polymer;

- Bituminous;

- And bitumen-polymer.

Why choose a built-up roof?

What is special about the roofing material that millions of people choose? It has many advantages, which keeps it on the market:

- Little weight. Thanks to this fact, it becomes very simple to install this roof. It is also much easier to transport.

It is better to transport rolls of a built-up roof in indoor transport. This is necessary so that no atmospheric phenomena can harm the material.

- Easy to clean. Roofs from surfaced materials differ in a simple way of laying. There is no need to regularly monitor and care for her.

- Strength. Thanks to modern materials that make up the roof, it can withstand quite strong loads while maintaining high elasticity.

- Good hydro and sound insulation.

- Fire safety.

- Resistance to various weather factors. Such a coating does not deform from heat or water.

- Harmlessness. Surfaced material does not emit any hazardous substances into the environment, which makes it environmentally friendly.

- Availability. By purchasing such a roof you can significantly save money. Having similar characteristics and advantages, a soft tile roof, for example, cannot boast a low price.

All the advantages of surfaced materials allow us to conclude that this is the best choice if you need to build a house or any outbuilding.

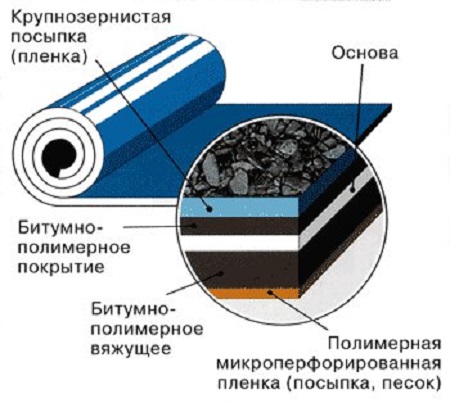

Structure of coiled materials

Rolled-over roofing roofs, which are created exclusively on the basis of fiberglass, fiberglass or polyester fabric, are very popular today. From above, to impart waterproofing abilities to the material in production, it is coated with special bituminous compounds.

Usually such a soft roof has several layers. At the same time, the topmost surface is shale, sand, and mica chips protection. But the bottom layer is a fused material. As a rule, this is a film made of polyethylene, which burns very easily.

Surfaced roofing requires proper storage if there is still a lot of time before installation. In order for it to retain all its technical characteristics, it must be kept exclusively in an upright position. At the same time, heating devices should be about a meter from the rolls. You need to hide them from direct sunlight.

The characteristics of the built-up roof on a different basis

The most reliable today is polyester. Moreover, such material is more expensive. It consists of polymer fibers that are arranged randomly. In order to break such a roof, you need to make an effort, at least at 35 kgf / cm.

The soft deposited coating may be based on fiberglass. It consists of thin glass fibers that are intertwined. Such material is considered even more durable.

Fiberglass - the most low-quality option, with low strength. When transporting rolls, the material can easily deform or even crack. Typically, this material is not used to cover the roofs of buildings and residential buildings.

Stages of mounting a built-up type roof

Before laying the material, be sure to prepare the base under a soft roof.

An obligatory layer before laying should be insulation. Moreover, they can serve as expanded polystyrene or mineral wool. An additional layer of waterproofing is already laid on top.

Soft roof made of surfaced materials implies the presence of a solid base. The better it is made, the easier the installation will be. Such a basis may serve:

- Flat slate;

- Tree;

- Concrete;

- Metal.

The base is thoroughly cleaned, and then additionally coated with a special primer. In its absence, you can simply dilute bitumen with gasoline or kerosene.

The main point in installing the roof is its proper adjacency. It is not easy to do this if you do not know the basic techniques.

Ways of joining a soft roof to a wall

There are only 2 options for laying a built-up roof:

- Overlap. In this case, the material is laid so that it ends on a vertical wall. A special abutment panel is already superimposed on top. To strengthen it, a wooden lath is specially nailed to the wall. They beat him to her with nails. The uppermost part of the covering panel is closed with a metal “apron”.

- Into the plug. This method involves fastening the roof panels and adjoining a wooden lath, which is installed directly on the base of the roof and wall. The junction itself is neatly closed with a metal sheet.

Pbuild-up roof installation process

Even a layman will cope with the laying of roll material. This can be done in several ways with partial or continuous deposition. The first option helps to avoid bubbles when laying.

Surfaced roof is mounted most often in several layers. Moreover, the flatter the roof, the more layers of material will be required.

When installing with partial deposition, it is very difficult to find the place of leakage, if such a disaster suddenly happens during the operation of the roof.

If there is a slope of up to 15 degrees, you will need to immediately apply a three-layer roof. If the bias is even greater, then 2 layers will be enough. Absolutely flat roofs require the use of 4 layers of material.

Gas burners help to lay the roof. With their help, they only heat the material so that its lower layer melts and then adheres to a flat base. In no case should it be allowed to burn.

Bitumen must be heated so that it even slightly extends beyond the edges of the roll. This is the only way to guarantee a reliable and sturdy styling. As soon as the built-up roof is in place, all seams should be carefully checked so that they do not leave the base. Otherwise, they should be glued with a burner.

The second, third and other layers of the roof are necessarily laid with an offset in relation to the previous roll. This is necessary so that the joints do not coincide, and the coating was much more reliable.

The service life of a soft built-up roof is at least 10 years. It all depends on the number of layers of material. The more there are, the more durable the roof.

Such a coating for the roof is the most optimal and high-quality option. All installation work is carried out quickly, the material itself is inexpensive, and the result is very good. That is why surfaced rolls occupy the first lines of the rating of popular goods in the roofing materials market.

Alas, no comments yet. Be the first!