It is believed that wood is not a good material for roofing, but this statement can be argued. Over the centuries, our ancestors built houses precisely from wood, there was practically no other choice. The market could not give so many diverse materials that are today.

We will examine in more detail how practical it is to use wooden roofs these days, what they are, and consider their device in more detail. Also, such questions as how easy it is to cover such a roof with one's own hand will not be ignored, and, of course, we will not disregard such a question, how long it can last.

Content

Unity of material - striving for harmony

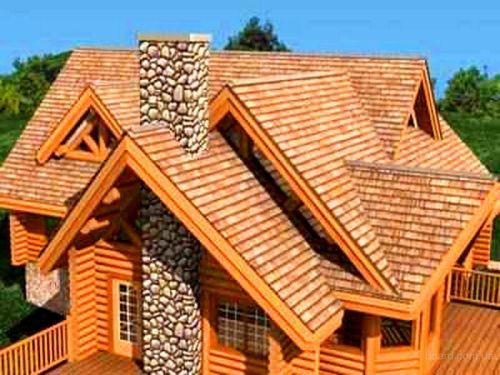

The roof of a wooden house made of the same material (wood) - it looks very beautiful.

And when you consider that wood is one of the most ancient materials that people have ever started working with, it becomes clear that wood is one of the most natural materials suitable for roof construction. Therefore, even after millennia, such roofs of wooden houses do not lose their attractiveness, the house looks interesting and original, which distinguishes it from other buildings. Moreover, he will undoubtedly always attract attention to himself with his outlandish appearance.

Although this material today receives its “rebirth”, it cannot be said that it is a very cheap material. On the contrary, at its price it is considered one of the most expensive types of roofing. As for construction work, laying such a roof is not an easy task.

But, if the designs of the roofs of wooden houses are correctly developed, then their construction will be completed faster. Such a wooden roof can serve its owners for many years and at the same time always delight with its unique design, different from other houses.

Of course, in order for the house to look good, the wooden roof should be in harmony with the general view of the entire structure. Therefore, you need to carefully select the type of roof of wooden houses, as well as the type of wooden coating used.

Wooden houses, without a doubt, have many advantages. This is the environmental friendliness of the materials from which it is built. If you approach the processing of logs before construction, then it will stand for almost a century, and its unique properties in thermal insulation and other parameters make this option at home a very good choice.

But the house made of wood, unfortunately, also has its drawbacks, the main of which is the ability to change its geometric shapes over time.

More simply, this is a change in the structure of the tree under the influence of various factors, sharp temperature changes and humidity. Therefore, when building such a house, there are some details that you definitely need to pay attention to.

First of all, such subtleties and details affect the methods and procedure for installing windows and doorways, holding a certain time for shrinkage of wood, as well as methods of installing wooden roofs.

When constructing wooden houses, factors such as shrinkage of the tree should be considered. For different lumber it can be in different limits. For example, if the log or beam is raw, then the shrinkage will be 10%, and if the profiled beam is 3-5%.It is worth remembering that during the construction of wooden houses, as well as during its design, all labels must be given in two versions: before shrinkage, and also after.

Common Roofs of Wooden Houses

It should be noted that it is rarely possible to meet a house made of wood with a gable roof. Such a roof of a wooden house is not very practical, and if you take into account that the shape of a pitched roof is not very beautiful, then you often choose other, more interesting options.

The existing types of roofing for a private house are so diverse that choosing a one on which a roofing material from wood will look good is a rather difficult task. However, regardless of the type of roofs, a wooden coating will always look original, original and unique. Conventionally, all types of roofs of wooden houses can be divided into the following categories:

- Hip roof (which has not one slope, but several);

- Attic - in other words they are also called broken roofs;

- Gable - one of the most traditional forms of roofs;

- Multi-gable - roofs with a large number of gables;

- Hipped roofs are another kind of hip roofs that have equal, uniform in shape, slopes;

- Semi-hip (there are both gable and four-gable).

If the roof projects of wooden houses were originally conceived in such a way that there was a wooden roof with slopes, then this can bring additional amenities, such as:

- Excellent drainage of water from the roof;

- Good thermal insulation properties of floors;

- Elimination of snow cover from the roof under own load;

- The possibility of using cheaper materials.

And this is not all of these advantages, but only a few of them.

What materials can be used to create such a roof

Most often, to create a roof from a tree, use the following materials:

- Shingles - are rather thin plates that chip from the whole trunk of a tree (alder, spruce, aspen);

- Shingles - planks that are specially cut and have a thorn-groove lock connection;

- The spindle is a material remotely resembling tiles; these are irregularly shaped planks that are made by hand;

- Ploughshare - very much like a spindle, the only difference is that the planks are made in the form of a curved blade, and the lower edge is often made curly;

- Tes is a edged board that is simple in form and execution, which is made from coniferous species;

- Wood chips - a material that is very similar to shingles, only it is much smaller in length.

Of all types of lumber, it is best to install pitched wooden roofs. The slope angle of the slopes can be any (from 20 to 80 degrees). If the slope of the roof is large, this can lead to a significant cost overrun of building materials, but on the other hand, such a roof will last much longer.

Technological features of installing a wooden roof

Different materials from wood, of course, suggest different ways of constructing roofs, as well as their rafter systems.

We select only the main types of roofs from lumber:

- Wood chip roofing;

- Clad wooden roof

- Lapped wooden roof;

- Wooden shingles;

- A lapped wooden roof, which is made in two layers;

The most difficult wooden roof, which will be very difficult to mount by yourself, is, of course, a wooden shingle roof. Therefore, if you want this material to decorate the roof of the house, it is best to hire competent specialists who will cope with this work.

Shingles are small planks, the length of which is from 40 to 70 cm, and the width reaches only 10 or 15 cm. Most often they are pricked only with their hands, sawn ones are much less common.

The difference between sawn shingle and chipped shingle is that the sawn shingle has a rough surface, while the chipped shingle has an even surface.

These planks are made from coniferous species, less often oak or aspen is used. Laying all the material takes place on the crate, which is made of timber, or on a continuous crate of boards.

During installation, each shingle plank is nailed with the top edge to the battens lath using nails.

Depending on the type of wood, you need to use various nails. If this is larch or, for example, cedar shingles, then you need to use copper nails, as for the rest of the species, then you can already use any.

The shingle is laid in two layers, if it is a building for economic purposes. In three layers, it is recommended to lay the roofs of houses. When you need the highest level of reliability, they stack the shingles in four rows.

When laying in two layers, one covers the other row halfway; if laying in three layers, then two thirds.

Planks that are installed on the crate are also slightly worn (their upper part) to reduce the entire thickness of the roofing. The most common type of stacking is the type of flipping, this is when one of the edges of the plank in the upper row falls in the middle of the lower plank.

All planks must be specially treated with an antiseptic before laying, and for safety (from fire), they are additionally treated with a flame retardant (compound from fire).

Laying materials such as a spindle or a ploughshare takes place in exactly the same way. The difference is only in the shorter length of the planks, so you need to install batten bars more often.

One of the best wooden roofing materials is larch. It makes a solid wooden roof rafter.

The simplest wooden roof is a roof

One of the easiest wooden roofs to build is, without a doubt, a wooden roof made of tez. However, the durability of such a wooden roof of houses not too high.

Boards used to be made by splitting a whole log along its entire length. They were broken strictly along the wood fibers, while preserving all the properties of the tree. Therefore, they probably served for a very long time (from 100 years or more).

Of course, one should not expect such longevity from simple sawn boards, since the natural structure of the wood sheet has already been violated.

There are two types of laying of the roof roof:

- longitudinal - with this method, all boards should be laid parallel to the direction of the ramp;

- transverse - in this case, the boards should be laid parallel to the ridge.

Basically, the second method is used only in the construction of temporary buildings, since it is quite simple. The boards are stacked from bottom to top, while you need to make sure that one row of boards overlaps the previous one by at least 5 cm. One board is fixed to each lag with just one nail.

The longitudinal method already has several options:

- Back to back in two layers. The boards are laid with the offset of the upper row relative to the bottom with a shift of half a board, while the distance between the boards in the same row is 0.5 cm (for drying);

- Along the ramp in a swing. The boards of the lower layer are laid with a distance from each other - 50 mm, and the upper layer overlaps them and enters each adjacent board also by 50 mm

- Shelter of the bottom row with a nasal filler. The bottom layer is laid with a continuous coating, and the joints are overlapped with boards with a width of less, overlapping also with 50 mm boards of the lower layer.

It should be remembered that no matter which option you choose, in any of them two nails in each block should be nailed to the crate of the upper row board. Typically, the pitch of the crate is from 600 to 800 mm. The thickness of the boards is usually from 18 to 20 mm, and the beam has a cross section of 60 x 60 mm.

It is better not to lay under the roof of a tree, layers of hydro or vapor barrier, since wooden floors do not form condensate due to the rather low thermal conductivity. And if you block the movement of air, then it can likely cause damage to the tree.

Over the past centuries, mankind has learned to create a variety of roofs, and a variety of materials can amaze anyone. However, wooden roofs still remain in demand, since wood is a reliable material that has been tested for centuries by our ancestors. It is environmentally friendly, and living in such a house is not only pleasant, but also beneficial: the air is clean and healthy. At the same time, the roof of the house looks original, fresh, beautiful and fashionable!

Alas, no comments yet. Be the first!