Building materials today must meet many characteristics, such as strength, reliability, resistance to any weather conditions. And in this sense, polycarbonate roofs are not inferior in many respects to other types of roofing materials.

This is a fairly new roofing, but it is becoming increasingly popular not only among summer residents (after all, you can make excellent greenhouses with it), but it has been successfully used in creating unique roofs of private houses, arbors and arched ceilings.

Polycarbonate, like glass, perfectly transmits light, filling the room with natural light, making any space under it lighter, and literally saturated with air. Such a room becomes more open, comfortable and spacious.

Polycarbonate was simply “doomed to success,” and many designers have successfully used it in their projects, making unique and original designs, embodying their ideas and fantasies 100%.

Content

The use of polycarbonate, and its functional features

Since polycarbonate is, first of all, light-transmitting material, the tasks that are assigned to it are simple: to make the room brighter, to introduce additional elements of natural light. Recently, it is increasingly replacing glass during construction work.

Here are just the basic requirements that a polycarbonate roof must meet:

- First of all, polycarbonate should well illuminate the room;

- And also to protect the entire space from excessive light in those areas where this is not required;

- In case of fire hazard situations, such a roof must meet the requirements of ventilation, to prevent the spread of fire in case of fire;

For the most part, all the characteristics and requirements that apply to other types of roofs can easily be applied to polycarbonate structures. Basically, this is a good waterproofing in the winter season, which meets the basic vapor barrier properties. Of course, a polycarbonate roof must comply with all soundproof standards, as well as many others.

The versatility of polycarbonate as a building material gives a huge scope for imagination. That is why you can meet him on the roofs of various shapes and sizes, and sometimes the most exotic and sophisticated. From traditional and common pitched - to various roofs in the form of arches, domes, tents and even polygons.

Polycarbonate was very widespread in the construction of visors of buildings, as well as in the manufacture of bus and trolleybus stops, since it can take on all kinds of severe weather conditions, from roasting and scorching sunlight and to hail, rains and hurricanes.

In the hands of an experienced designer, this flexible and versatile material can sparkle with “special colors.” For example, you can create an original arbor with a dome-shaped roof for warm friendly gatherings. A polycarbonate roof for a gazebo or a simple carport will protect you well from rain and snow, creating the illusion of open sky and space. Is not that great?

If you decide to build a polycarbonate roof yourself, think about it, but is it possible? If you have such confidence, you can safely proceed, but if not, then it is best to invite outside experts. Indeed, for the construction of the roof, it is necessary to conduct competent calculations of all loads.

The main advantages and advantages of polycarbonate

This material has a lot of advantages, we give only a few of them:

- one of the main advantages is, of course, durability. With proper operation, such a roof can last from 10 years or more;

- excellent transparency of the ceilings from this material gives natural lighting in the rooms, creating the feeling that you are on the street;

- thermal insulation properties (with the right installation technology) are also significantly high;

- since the material is quite light, due to this, the load on the bearing walls is very small, and therefore the bearing properties are very high;

- good flexibility of the material makes it possible to use it for many needs, including using in the construction of arched ceilings and in the manufacture of even domed roof shapes;

- excellent resistance to chemical influences of various nature;

- sufficient fire resistance is also a significant advantage in favor of this material.

If we consider other characteristics, it can also be noted, for example, in the honeycomb type of material high resistance to shock. During the tests, it turned out that this material has excellent ability to absorb energy. Therefore, with abundant hail, you can not worry about the safety of the roof. She will be under reliable control.

Given all the above characteristics, we can say with confidence that, perhaps, this material is the best substitute for glass. Polycarbonate has good strength characteristics combined with excellent light transmittance features.

Polycarbonate - varieties and species

Polycarbonate is a type of transparent material that is very similar to glass, but made from polymers. Due to the special plasticity, as well as the flexibility of this material, it can be classified as engineering materials. Resistance to sudden changes in temperature conditions (from -40 to +100) distinguish it from other materials, and in this sense it is much more reliable than acrylic.

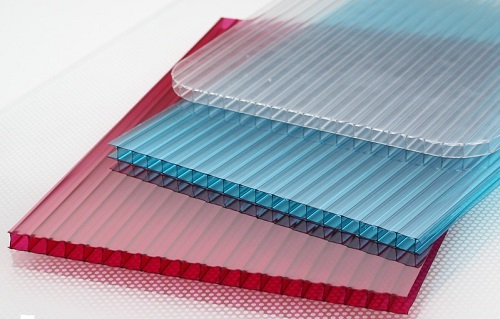

Available in monolithic panels, as well as in the form of structured sheets.

When a polycarbonate roof is mounted, monolithic slabs are most often used. He can successfully compete in the degree of illumination with glass. And thanks to its other properties, such as ductility and flexibility, it can also be used for the manufacture of conventional or fancy roof shapes (domed, flat, pitched).

But for a long time, monolithic slabs were not so popular because they had a significant difference in price compared to structured polycarbonate.

The most widely used structured sheets. On the market you can often meet them under another name - cellular or cellular polycarbonate. The main area of its application was the overlapping type of arches, as well as horizontal structures.

Small indicators of polycarbonate weight and resistance to shock, more and more lead it to replace traditional glass. And thanks to its flexibility, it is possible to create unique and non-standard forms and designs of roofs.

The main types of structures based on polycarbonate

Polycarbonate, as a building material, refers to a species that transmits light. Designs based on it can be conditionally divided into several types:

- installation of structures that must transmit light, and which are based on system profiles;

- structures with light transmitting elements;

- skylights, in the manufacture of which polycarbonate is used.

Using system profiles, you can design almost anything, any type of roof: tent, dome, hip. Many companies that specialize in the installation of polycarbonate roofs, as a rule, have ready-made solutions for different types and shapes of roofs, which can be applied at any time.

In the manufacture of various types of polycarbonate profiles, the following common materials are used:

- if you need to create large spans in buildings, then use steel profiles;

- aluminum is often used to create small spans;

- Of course, polycarbonate itself is used to create profiles.

Metal profiles can also be successfully used in a bunch of polycarbonate profiles.

If the design is intended to replace glass with polycarbonate, then such a light-transmitting element must meet the requirements of transparency.

Increasingly, polycarbonate is used for street lighting. This material proved to be excellent in flashlights. According to the characteristics and degree of transparency, it is not inferior to glass, but it also has some other properties. For example, excellent resistance to shock makes such lights "anti-vandal." Flashlights can have various shapes, types and sizes.

In addition to all of the above systems, polycarbonate is often used in the construction of skylights. At the request of the customer, if necessary, sometimes they make a symbiosis of simple glass and polycarbonate.

DIY polycarbonate roof - construction principles

When a roof is made of polycarbonate with your own hands, it is necessary to follow the basic safety rules. Do not forget to use gloves and protective glasses when working, especially this applies to a tool such as a grinder.

Before covering the roof with polycarbonate, you need to develop it yourself or order drawings of the future roof, its shape and dimensions from the construction company, and only then install it.

Installation and installation of a roof made of polycarbonate should not be any difficulties. After all, this material has a small weight, which means that all work can be carried out independently.

To begin with, when installing, it is necessary to design the roof truss system. Be sure to consider the future slope of the roof. The main rule: that the slope was at least 50 degrees, and if it is more, then it is even better.

The installation of the rafter system is divided into the following steps:

The first step is to make a supporting roofing system, and the roof slope should be at least 50 °, and the most optimal slope is 100 °.

Preparation of the roof structure includes the following steps:

- Rafters with a section of 60x40 or 60x80 mm are attached so that between the edges of the roof there is a distance of 1.04 meters and a little less (1.01 m) between the central axes of these rafters;

- Then, after setting the required distances on the rafters, various connecting and end profiles are fixed;

- A distance of two centimeters is measured from the very edge of the profile, and then stoppers are fixed using rivets;

- To protect against reflection of sunlight, the side surfaces on the plates are sealed with tape;

- The upper edge of the plate is pasted over with ordinary adhesive tape, and it is recommended that the bottom be glued with perforated (to protect against dust and unwanted insects from entering the cellular structure of the plates).

When the basis for the installation of the plates themselves is prepared, then you can begin to assemble them. With proper installation, the connection of the sheets will be waterproof, in this case there is even no need to process the joints with mastic.

When laying the plates, you need to pay attention to how they are stacked. Be sure to look so that the surface with the inscription "looked" up, and a small gap should be left between the plates (in the amount of not more than 5 millimeters for subsequent processing).

In the last turn, the covers are fixed to the profiles, and then the plugs are fixed, and the installation can be completed on this!

In order for the polycarbonate panels to serve for a long time and in good condition, they need care, the main task of which is to maintain the polycarbonate clean.

When instead of the usual roofs made of tiles or other usual materials, a polycarbonate roof was erected near the house, dirt or dust is often visible on it, which can be cleaned with tools such as a soft rag or sponge. It is not recommended to clean them with sharpened objects, as well as caustic preparations.

Proper and reliable care will give a long life to a polycarbonate roof, and it will delight for a long time with its cleanliness and brilliance!

Alas, no comments yet. Be the first!