The building materials market brings something new every year. Modern technologies in construction are developing, and, as a result of this, a number of new building materials appear. It would seem that everything has already been invented in the segment of roofing materials, but no, still something new and unusual appears.

So in the construction of roofs, materials not only of the traditional type, such as metal tiles, ondulin, but also coatings that let in light: glass and new polymeric materials, are becoming more and more popular.

This is a great way to create unusual, natural light-filled original solutions. And many designers today use light-transmitting materials as a necessary attribute in order to erase the boundaries between the external and internal spaces in the interior.

Content

Polycarbonate, features and applications

The main tasks that polycarbonate roofs must solve include increasing the illumination of interior rooms due to the high throughput of light penetrating this material.

Roofs from this building material must meet certain requirements:

- polycarbonate roofs should cope well with room lighting;

- provide protection from bright sunlight and reflected rays of those areas in which the production processes take place;

- also another important condition that roofs covered with polycarbonate must comply with is good ventilation in the event of smoke or the spread of fire in a fire;

- it is logical that snow should be easily removed from such a roof.

Polycarbonate roofs must meet all the same requirements that apply to other types of roofs. This is the presence of good soundproofing, waterproofing, as well as vapor barrier and other properties.

It must be remembered that polycarbonate roofs can have completely different shapes, not only in the form of slopes, but also take the form of arches, various versions of polygons, as well as domed ceilings

Types of Polycarbonate Based Structures

Since polycarbonate is a type of light-transmitting material, constructions based on it can be divided into several types:

light-transmitting structures based on system profiles;

designs in which there are self-supporting elements that transmit light;

also include lanterns and skylights.

Using system profiles, you can design almost any type of roof: pitched, domed type, gable, and tent. Those companies that supply polycarbonate profiles usually have already developed the most common solutions for various types of roofs, but they can also take on the creation of extraordinary turnkey solutions.

The materials that are most often used in the manufacture of profiles are the following:

- steel is used to create large spans in the building;

- aluminum is most often used in the design of small spans;

- Of course, polycarbonate itself is also used.

Metal-based profiles can be used with almost any kind of element that is light transmitting.

All structures that are based on light-transmitting elements should be made only of polymeric materials with sufficient transparency. Self-supporting elements can be made in the form of various segments or, for example, arches. Different structural elements can be opened in various ways, in some cases, opening is automatic.

Also, designs using polycarbonate are often used in flashlights. Such lights can be either protruding from the building, or in the form of a glass gap on the roof. Flashlights of this type can have a variety of shapes and sizes.

In addition to the systems listed above, polycarbonate structures can also be used in skylights.

If the customer wishes, in the attic floor a symbiosis of ordinary windows and polycarbonate windows can be used.

Types of Roofing Polycarbonate

Roofing polycarbonate is a transparent material that relates to polymers. Properties and plasticity give every right to attribute it to engineering materials. In terms of temperature resistance, it is much better than acrylic, can withstand loads ranging from -40 to +100 degrees.

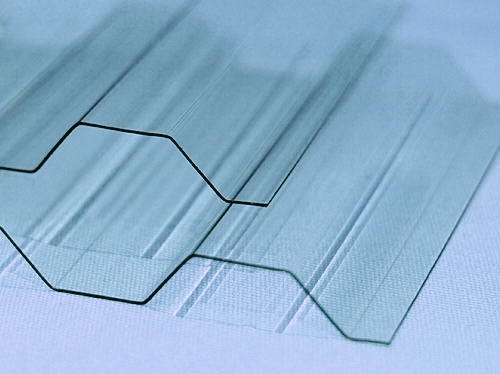

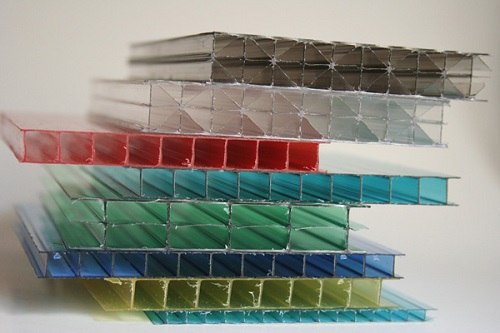

This modern building material is now offered in two forms: panels monolithic and structured sheets.

It is monolithic transparent polycarbonate that is most often used to cover the roof. It is, practically, an ideal material from which it is possible to create various types of roofs (flat type and with slopes). Moreover, in terms of transparency, it can even compete with glass.

But so far this material has not been very widespread in the construction of houses. This was due to the fact that monolithic polycarbonate plates are much more expensive in price than structured ones.

Structured sheets also have another name - cell panels or cellular. This is the most common type of polycarbonate in use. Basically, this type is most often used in horizontal or arched ceilings.

Such material weighs many times less than ordinary silicate glass, and much less than acrylic. And the flexibility of this material is such that it allows you to safely create structures of various geometries and shapes. Including the structure of the dome forms, whether with a round, oval or some other basis.

Advantages of transparent roofing material

Of course, polycarbonate products have their own strengths. Consider only a few of them:

- very light weight, which reduces the cost of roofing, and structures made of it can have ample opportunities (in terms of design ideas);

- fairly high thermal insulation properties;

- bearing capacity is also very high;

- coating transparency;

- the flexibility of the material, which contributes to the use for the manufacture of arched ceilings);

- high resistance to chemical influences;

- very good durability (the service life, according to the manufacturers, can be from 10 years or more);

- good fire safety.

Among other things, if we consider that they are still inherent in such a quality as strength (resistance to shock). The material was repeatedly tested for strength in various tests, and polycarbonate proved to be only the best, showing a very good percentage of energy absorption compared to other materials. And resistance to blows, for example, hail, is generally beyond praise.

Summing up all the advantages of this material, we can say that this is one of the best glass substitute to date. Especially if you use it when coating roofs to create natural light in rooms.

This material is especially popular for creating visors at the entrance to buildings, at bus and trolleybus stops.After all, polycarbonate can take on itself, as the hot rays of the scorching sun, and withstand torrential rainfall, hail, and even in the winter season in front of a snowstorm.

A polycarbonate canopy can also be an excellent roof for a garage, perfectly fulfilling the function of protecting the car from the weather.

However, a material such as polycarbonate can be used not only to protect peaks in buildings, but also serve as a good tool in the hands of an experienced designer, to create an atmosphere of coziness and hospitality on a suburban area. Spacious gazebo with a transparent roof for meetings and gatherings with friends, what could be better!

If you are confident in your abilities, then you can safely proceed to the creation of canopies or other structures based on polycarbonate, in other cases, it is better to invite specialists who competently design and build any type of roof according to the customer's request.

Widespread today, canopies in the form of arches or arches, as well as designs that include a large number of sheets of polycarbonate and metal nodes. It is worth saying that canopies, roofs for garages, as well as for bus stops and gazebos for a country vacation are traditionally popular among the population.

Polycarbonate roof - space for imagination

To make the upper floor of the house brighter, i.e. it would have “more air”, with the help of today's technologies it is possible to make this dream a reality by building a polycarbonate roof.

The material gives space and flight for imagination to create any forms that you may like. This roof is arched type, and hip, and even in the form of a dome. Moreover, in its design, at first glance, completely dissimilar materials can be used: PVC, glass, and, of course, polycarbonate.

Most often recently, cellular polycarbonate has been used to equip the roofs of country houses. As for the use of this material for other needs in a country house, cellular polycarbonate is still used in arranging pools, creating greenhouses or roofs of garages.

Abroad, this versatile material has been known for a long time, cellular polycarbonate has been used for arranging for more than 40 years, and in Russia it is only 10 years old, but the popularity of this material is growing every year. Indeed, in addition to its practicality, it can very well fit into the architectural ensemble of a country house with skillful combination with other elements of design thought.

The reasons why this material has gained such great popularity in the West are connected, first of all, with the ease and speed of its installation, with its plasticity, with ease of use, and, importantly for practical people, with the relative cheapness of cellular polycarbonate.

A cellular polycarbonate (honeycomb) roof is very reliable, it has a high level of tightness, as well as good shock resistance, and therefore they can be safely recommended for replacement, for example, glass.

Therefore, plates of cellular or cellular polycarbonate are often used when replacing glass in the frames of windows and transparent partitions with this material.

Speaking about the great plasticity of polycarbonate, it means that it can be given to almost any shape. Of course, the bending angle is not infinite, and if the bending load is very large, then the cell polycarbonate roof will not be so transparent, and if the permissible loads are exceeded, some internal damage can occur.

It is worth remembering that all translucent materials, including roofs made of cellular polycarbonate, must be washed and at least 2 times a year. If these are roofs that are at high altitude, then this must be done with extreme caution or a team of industrial climbers should be called in.

Winter garden under polycarbonate roof

To build a winter garden using familiar materials you need to spend a lot of time and effort. A cellular polycarbonate roof is one of the most important and complex elements in the process of creating the entire building. Glass and concrete have long been time to change to modern technologies of the future, which include polycarbonate.

At the stage of designing a winter garden using simple materials such as glass and others, it is necessary that the entire structure and roof, in particular, meet certain requirements of strength and safety. But if polycarbonate will be used in the construction of the roof, then the safety requirements can be significantly reduced. After all, this material is not glass, it will not break if something falls on it. For a glass roof, it is necessary to additionally strengthen the roof with a special film, which is glued to two glasses for their greater strength. And for a polycarbonate roof, this is completely irrelevant, because the material is so resilient and flexible that if foreign objects fall on it, it will not break into small pieces, but will repel a foreign object.

For greenhouses or greenhouses, polycarbonate will also be an indispensable material, because polycarbonate panels allow only a certain spectrum of ultraviolet waves to pass, which has a beneficial effect on plant growth.

The roof is made of cellular polycarbonate, its design features, combined with glass and other building materials can make a winter garden or even a living room unusually beautiful and even a little fabulous. In rooms with an "airy" polycarbonate roof, it will be pleasant not only to be, but also to hide from any weather, enjoying peace and harmony.

Alas, no comments yet. Be the first!