The plastic roof made of translucent material, quite deservedly, is currently very popular. And this is quite logical. After all, this material transmits light very well, which means that you can create different types of roofs, and at the same time in the daytime in a room with such a ceiling it will always be light.

Previously, plastic roofs were mainly installed for office buildings, used for awnings or peaks. Today, one can see an increasing interest in the creation of plastic roofs in the private construction sector.

If you take the basic materials, then for the manufacture of plastic roofs you can find materials such as polycarbonate and polyvinyl chloride. Let's try to describe each of these materials in more detail.

Content

Polyvinyl Chloride - Great Roofing

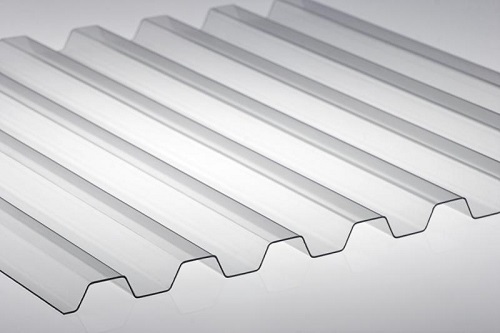

If you look at the PVC sheet in cross section, you can see that it is executed in the form of a wave. The choice of this form is not of random origin. Due to the wavy shape, the sheet appears additional rigidity.

It is worth noting that a roof made of such a material is strong enough (although its basis is plastic). It can perfectly protect from rain and snow, as well as withstand large wind loads. With all this, polyvinyl chloride can perfectly transmit natural light, including sunlight.

A plastic roof can most often be found when arranging canopies or beautiful arbors, as well as verandas or terraces in private houses.

The use of PVC sheets is safe and harmless. They are considered environmentally friendly material, since in it, unlike other building materials, so-called plasticizing additives are not used.

When using a roof made of PVC sheets, the following advantages can be distinguished:

- this material has a large margin of safety, but also great flexibility;

- ease of installation due to the flexibility of the material;

- sufficient durability (more than 15 years);

- resistance to harmful substances, alkalis, ultraviolet radiation, as well as certain types of acids;

- low degree of ignition of this material;

- good soundproofing properties;

- the material is not a conductor;

- high impact resistance characteristics.

In favor of this material, the possibility of using it under various temperature conditions (from -60 to +60) can also serve.

When a plastic roof is assembled with your own hands, then the PVC sheets will not cause much trouble, they are very easy to process. They can be sawn, cut, glued, welded, and also bent, both in the cold state and after heating.

Remember that this roofing material is not recommended for use on roofs whose angle is less than 6%.

Sheets should be overlapped during installation, but the overlap itself should be at least 20 cm. In this case, the distance from the extreme edges to the mounting holes should be more than four centimeters, and better if there is even more. If it is necessary to cut the material, then you can quite successfully use a hacksaw for metal.

Installation is best done in the warm season, the temperature during installation work should be at least 5 degrees recommended by the manufacturer. Fastening sheets is carried out using self-tapping screws. But in no case can you punch sheets, it can just damage it, and it’s best to drill them.

During installation work when laying sheets, it is very important to ensure that the protective coating during installation is on top.

Polycarbonate sheets - a modern glass substitute

During construction, glass began to be replaced more often with polycarbonate sheets. And there are reasons for this. Low price indicators, good strength characteristics, as well as excellent light transmittance allow you to slowly but surely win ground against glass.

Polycarbonate sheets are used in various areas of private construction (gazebos, awnings, roofs of verandas and terraces) and in urban areas (bus stops, parking lots, exhibition centers, market awnings, visors of buildings). Recently, this material has been used more often where the use of anti-vandal materials is necessary.

The polycarbonate roof allows to achieve a large degree of expressiveness of buildings and structures in architectural terms. First of all, thanks to its characteristics, which allow you to create from polycarbonate, almost any necessary form.

In private construction, you can find greenhouses, conservatories, greenhouses and original greenhouses, all thanks to such qualities of this material as flexibility, durability, and excellent light transmitting properties.

It is worth noting that many companies have already realized that the popularity of this material will only grow. They already have ready-made solutions in their arsenal for any types and types of roofs and can quickly mount and install everything if the client pays well.

Plastic roof repair do it yourself

Installation of plastic materials is not difficult, since the weight of the sheets is usually very small, which means that repair work is also quite simple. First of all, it is necessary to determine the place where the damage to the plastic cover occurred.

Having decided on the place of damage, it is necessary to replace the damaged area. To do this, you need to purchase in the building materials store the same sheet of plastic coating that was before.

Making a plastic roof with your own hands using ... bottles

Of course, for many, such a plastic roof covering will be unacceptable, but from the point of view of economy, it will be a great option for creating a roof, for example, a barn or an original arbor.

In this case, building material can literally be found at every step. Creating such a roof can be not only an original way to use unnecessary bottles, but also serve as a concern for environmental protection. Everyone knows that plastic bottles do not decompose in the ground, which means that having built such a roof, you can safely consider yourself an environmentalist !!

But to create it you need plastic bottles (in large quantities) of approximately the same size. Then they need to cut off the bottom and neck so that as a result of the manipulations a tube is obtained. After this procedure, it must be cut lengthwise. It turns out a kind of plastic "shard" with dimensions of 30 × 25 centimeters.

First of all, you need to straighten the resulting sheets, for which you can use an iron. Warm it a little and smooth the shard through a sheet of paper. Then, using the same iron, it is necessary to fuse several sheets with a small overlap, to obtain a larger sheet of plastic.

The final step will be fixing these sheets on the roof with a construction stapler, while the wood frame should be prepared in advance.

To give a bottle roof a more interesting look, you can create a mosaic roof using multi-colored pieces of plastic.

Of course, you should not use such a roof for residential buildings. For this, it is better to use other materials, but as a way to amuse friends and acquaintances, you can build such a roof, for example, for a barn.

One can be guaranteed for sure, such a plastic roof will never go unnoticed, raising the spirits of others !!

Alas, no comments yet. Be the first!