For those who decided to equip the roof on their own and want to do it with the help of such roofing material as ondulin, the installation of which is not particularly difficult, we suggest that you familiarize yourself with the information contained in this article. First of all, you need to have an idea of what is ondulin.

Content

A bit about the material itself

Ondulin is called the roofing and facing material, which is original and has been produced by the French company ONDULINE for more than 60 years. Production is carried out at 6 factories located in France, Poland, Belgium, Spain, Turkey, Malaysia. Ondulin roofing is carried out in more than 100 countries and covers consumers of all continents.

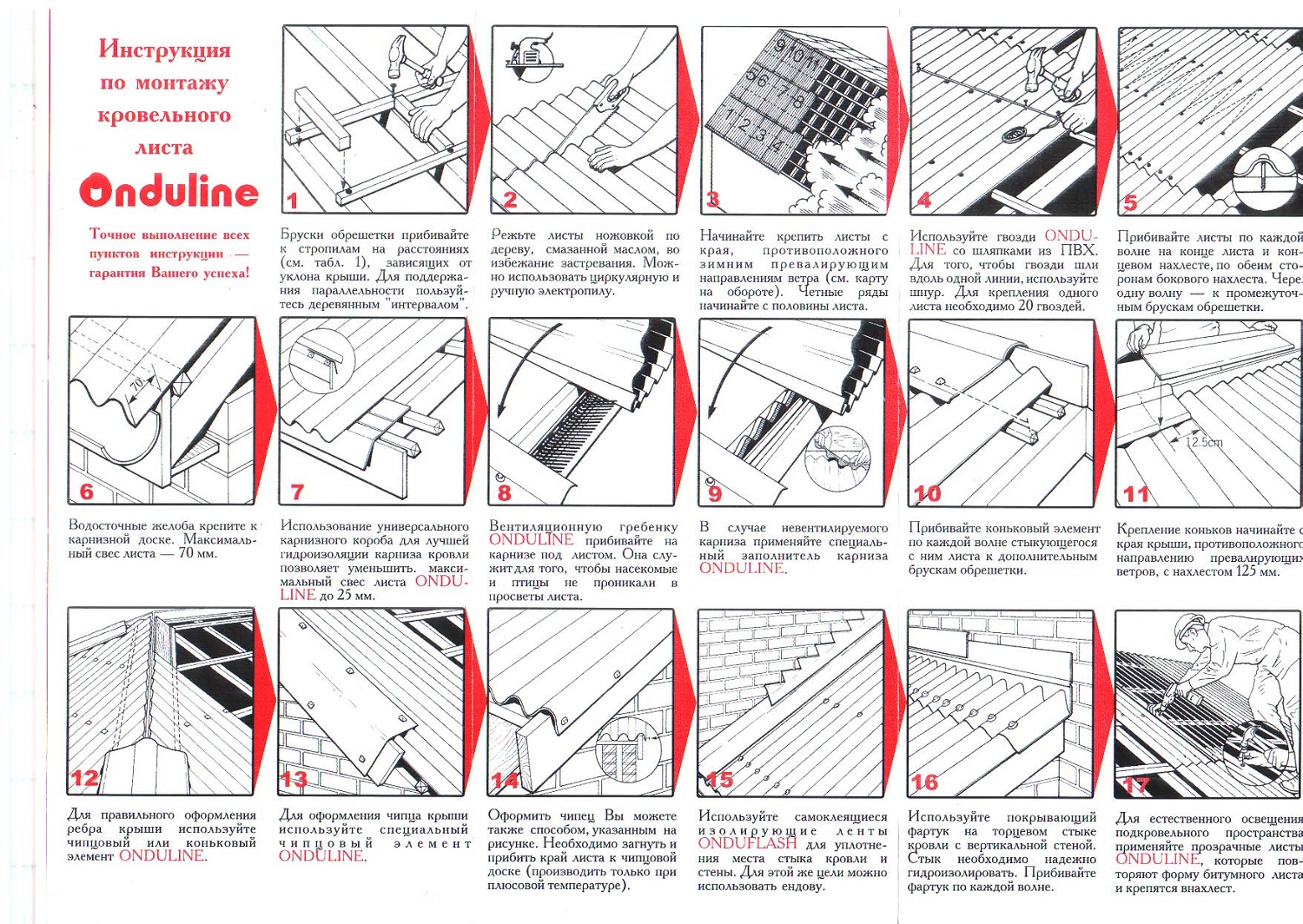

The use of ondulin is carried out almost throughout the territory of our country and does not have any restrictions due to climatic features. The undulating sheets of ondulin cover cottages and private houses. The lightness of the material allows it to be used to cover old roofs over slate or metal that has become unusable. Installation of a roof from ondulin is quite easy and therefore it can be done on its own. For this we need such instrumentslike a saw and a hammer, as well as accuracy in work and following the instructions for mounting sheets.

Due to the aesthetic appeal, flexibility and ease of installation, ondulin has gained popularity for covering trade pavilions, various peaks and canopies, as well as cafes and outbuildings. A light roof, when it is not necessary to erect prefabricated commercial buildings, is what many entrepreneurs need. At the same time, do-it-yourself installation of ondulin can be done on top of an existing old coating without resorting to disassembling it. The amazing lightness of ondulin (approximately 3 kg per 1 sq. Meter) allows you to update the roof without exposing the interior to atmospheric precipitation.

The sheets of this roofing material are perfectly bent along the wave. If the radius of curvature is 5 meters or more, then sheets can be laid on curved surfaces. Laying ondulin can be carried out not only on the roof. They can be tiled and vertical surfaces. With it, you can build a fence or waterproof screen.

Onduline is a durable material with a warranty period of 15 years, and in practice has been in operation for 50 years. Sheets of material do not contain harmful substances, such as asbestos. They are made from environmentally friendly materials that are safe for human health.

Ondulin, reviews of which you can read on the Internet, has a hygienic certificate, as well as a fire certificate and certificate of compliance. This material perfectly tolerates various climatic conditions - from hot tropical heat to Siberian frosts. If the crate for the ondulin is made in the right way, then the roof of the ondulin can withstand a very large snow load. Tests conducted in the UK and the USA indicate that this roof can withstand hurricane winds up to 192 km / h. Ondulin sheets are so strong that they are practically impossible to break.

Ondulin leaf consists of four components:

- disciplined bitumen;

- cellulose fibers;

- mineral substances in the form of a filler;

- thermosetting resin and mineral pigments.

Coloring of the sheets is carried out before impregnation with bitumen, so that the color becomes particularly stable.

Covering the roof with ondulin involves the following basic colors - brown, red, black and green. Thanks to the originality of the profile and the texture of the sheets, the coating perfectly combines with the stone and wooden walls of the houses. With a combination of sheets of different colors, you can create an original and unique roof.

By opting for ondulin, you can save on preparatory work. The light weight of the sheets does not require reinforced flooring throughout the house, which cannot be said when the finish coating is made of metal tile or slate. The crate for ondulin should not be continuous, which facilitates the weight of the rafter system and allows you to save on materials.

Laying sheets can be made in whole or they can be cut into 2 or 4 parts. It is possible to produce a combination of colors and give the appearance of the roof the desired look. At the same time, the waterproofing properties of the roof do not suffer and you can install the roof from ondulin with your own hands.

Laying ondulin on an old roofing

You can also mount ondulin on an existing old coating. Moreover, it serves as additional thermal insulation of the roof. In this case, the new crate is stuffed onto the existing roofing material. The step of the crate is determined taking into account the slope of the roof and the recommendations given by the manufacturer of the ondulin. A longitudinal counter battens and a standard transverse battens for fastening sheets are installed on the existing roof. When deciding how to cover the roof with ondulin, you provide in this case sufficient ventilation clearance. As a crate, wood with a section equal to the wavelength of an existing old coating is used. As a standard, it is 50x75 mm, the transverse ribs are 38x75 or 38x50 cm.

Foundation preparation

As a basis for ondulin (euro slate), boards, OSB boards or moisture-proof can serve plywood.

The step of the crate is within 61 cm. When the roof slope is less than 1: 4, the optimal crate pitch along the axes is a distance of 35-45 cm. When deciding how to cover the roof with ondulin, keep in mind that the size of the side overlap is 1 profile wave, and the end - 20 cm. When the slope of the roof slope is less than 1: 6, then solid flooring is used. In this case, the lateral overlap will go in two waves, and the end one is 30 cm. Where the roof slope is more gentle, it is not recommended to install ondulin, since there will be difficulties with the descent of snow and water. As a result, constant leaks can occur, leading to negative consequences. In latitudes with a lot of snow falling, the step of the crate is better to shorten to 30 cm. Ondulin laying on roofs with an angle of inclination of 15 degrees and above, the lathing is done in increments of 60 cm. The lateral overlap is done in one wave, and the end overlap is 17 cm.

We mount ondulin sheets

Roofing material ondulin by weight is considered very light, since it weighs only 6 kilograms. For this reason, lifting and stacking sheets is not very difficult. To fasten the sheets to the base, start from the bottom row of the edge of the roof, which is the opposite of the prevailing winds. When we cover the roof with ondulin, it is attached to the crate with the help of special nails with a decorative hat. Nails are driven into the base vertically along each wave in its upper part at the end of the sheet in place of the end overlap, as well as on both sides of the lateral overlap. Nail washers should fit snugly against the sheet, but not push it through. If the nail is hammered incorrectly, it can damage the ondulin sheet. Therefore, when installing ondulin with your own hands, nails should be driven strictly in the perpendicular direction. In the case when it was not possible to do this correctly, the nail is removed.The resulting hole is smeared with a special solution and closed with a nail.

First of all, the second and penultimate wave is fixed, then the geometry of the roof is checked, and only after that the remaining nails are beaten. To the intermediate bars of the crate, the ondulin is mounted through one wave. Stacking of ondulin, the installation instructions of which give specific recommendations, is carried out taking into account the fact that 20 nails are required for one sheet. The eaves overhang of the ondulin sheets should have a width of not more than 50 mm. Each subsequent row of coating is laid starting from half the sheet. This is done in order to avoid joining four sheets at once in one place. Ondulin, the installation of which is carried out in this way, allows you to make the roof more airtight.

Cutting the sheets of this roofing material is done with a hacksaw on a tree or with the help of a power tool (circular or manual electric saw). When using a hacksaw, it must first be lubricated with oil, then it will not get stuck in the material.

To know how to cover the roof with ondulin, it is important to strictly observe even minor trifles. For example, you need to use a tightened rope in order to produce fastening of sheets of ondulin strictly along the line of the battens.

The next step is to check the roof slopes for their rectangularity. Whether the plane has a curvature or not, you can determine visually or resort to measuring rectangular slopes diagonally. If they are the same, then we can assume that everything is in order. When this is not the case, the ondulin, the installation instructions of which stipulate the rules for the installation of sheets on oblique slopes, must be laid correctly.

Installation of additional elements

Installation of the plank of the ridge is made after the installation of roofing sheets on all slopes of the roof is completed. The ridge is fastened with nails at the same time as the upper edge of the ondulin sheets and the sealant. If you are thinking about how to cover the roof with ondulin in the best way, then for the better ventilation of the under-roof space under an ordinary ridge, an additional ventilation ridge is also installed. Thus, faster ventilation of the air in the space under the roof is achieved. This affects the duration of the entire roof.

When deciding how to lay ondulin, one must take into account the prevailing wind direction. The fastening of the ridge elements starts from the opposite edge of the roof. Installation of the ridge plank is done with an overlap of at least 10 cm in length. When fastening the ridge, nails should be nailed into each wave of ondulin. The remaining accessories and metal strips are fastened using roofing screws. Laying ondulin as a finish coating, installation instructions of which are given by the manufacturer, the cornice strips are fastened on the cornice, and the wind and end strips are fastened at the ends of the ramp. In the place where the junction of the two slopes occurs, a groove and a valley are made, and at the junction of the slopes of the roof and walls, the wall adjoins.

If the question is how to cover the roof with ondulin, when it has a complex configuration, then the chimney pipes, ventilation outlets and antennas, valleys and junctions should be well insulated. For this, special strips are used and waterproofing sealants are used. The circle that the chimney has is covered with a special apron, and its joint is treated with sealant.

Ondulin, reviews of which you can read on our website, is a popular roofing material not only in European countries, but also in the domestic market.

Alas, no comments yet. Be the first!