The channel is one of the most common types of metal rolling. In cross section, it represents the letter P, and its walls can be straight, inclined or bent. The latter is characteristic of perforated profiles. The entire range of channels is divided by type of product and their size. Obviously, it will be difficult for a non-specialist to determine the required product parameters, so below we will tell you everything you need to know to choose one of the options.

Channel bars are used where it is required to work with big weight. They are much more attractive than beams, because they withstand loads directed to compression and bending, so that a rigid and stable structure is formed. Since the parameters of the product depend on its size, we will consider the scope of application of the most popular varieties.

Content

160 mm profile

Channel 16 has a sufficiently high strength, which allows it to work with very large lateral loads. Obviously, in the field of construction, such metal structures are indispensable. Such a profile often acts as floor beams or as an element reinforcing concrete structures. For the manufacture of metal truss channel 16 is also used, also this number is used in the field of outdoor advertising.

100 mm profile

Sometimes not so high strength is required, so a profile is chosen whose distance between the shelves is lower. Typically, the choice of a solution depends on the features of the future design, but one of the popular options is channel 10. It can be of several types. The most common are profiles that have parallel faces of the shelves, but there are also those for which the inner sides of the walls are inclined. The thickness of such a profile depends on its type. For example, the equal-channel channel 10 has a thickness of 2 to 2.5 mm, and the unequal channel is 3 to 5 mm. If you plan to order just such a profile, then you should consider its mass.

The weight of metal structures depends on their cross section. In this case, for a 10-centimeter wall and a ratio of b: s 26: 2, the weight of 1 meter will be 1.09 kg, and the heaviest bent equal-channel channel 10 can boast a weight of 4.3 kg per linear meter.

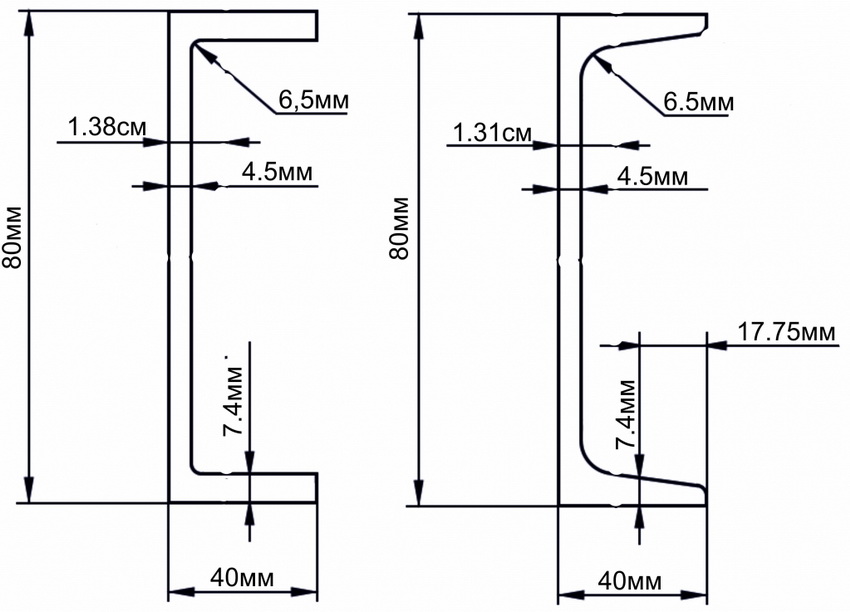

120 mm profile

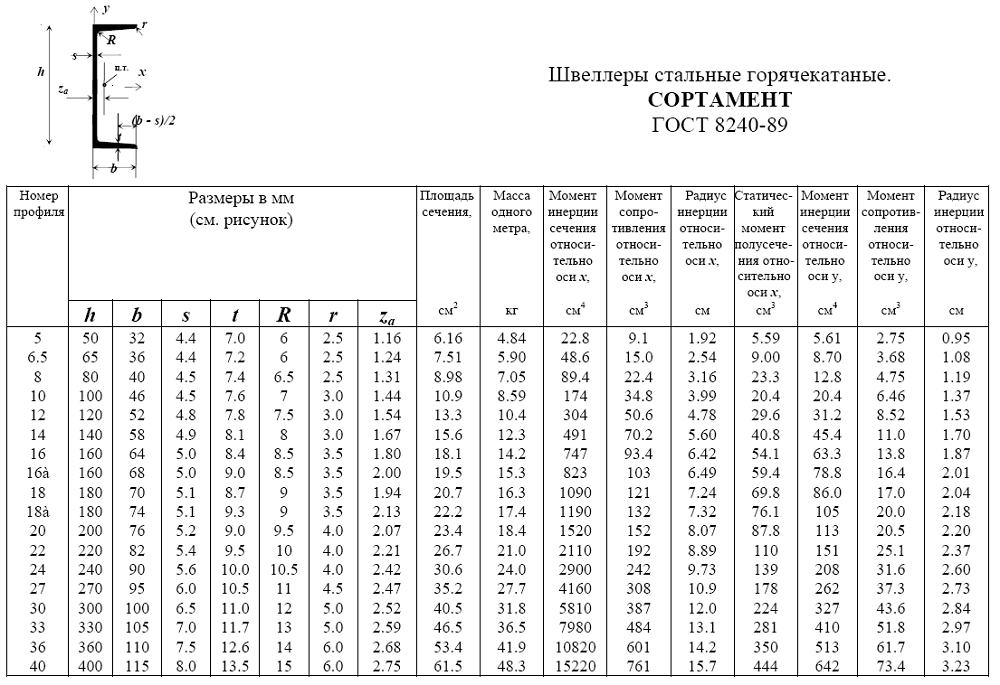

Sometimes a profile with a wall height of 12 cm is also used. Such products are manufactured in accordance with GOST 8278, if we are talking about their equally ravine variety, or GOST 8281 for unequal. Like other types of profile, this option may have thicker shelves, the inner edges of which are located at a certain angle. In this case, the channel 12 should have the characteristics regulated by GOST 8240. It is also worth saying that the rolled and bent profiles are distinguished by the production method. In the first case, a special rolling mill is used, and in the second, a complex of roll forming equipment. The channel 12 bent differs from the rolled one in that its ribs are smoother.

The use of one or another type of profile is determined by the project, but the properties of the metal must also be taken into account. Today you can even order the channel 12 perforated, not to mention classic or aluminum, so you need to take into account the steel of which brand it is made of. In GOST at the moment, the main characteristics of different types of profiles are considered and given.

200 mm profile

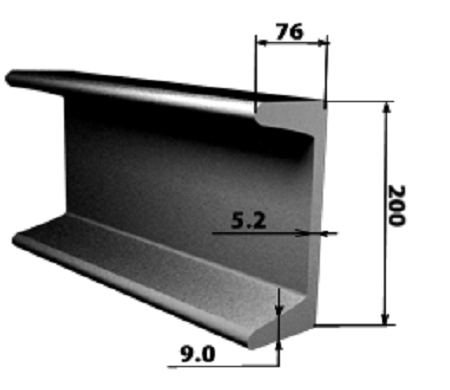

If the 12-centimeter profile can be used even in individual construction, then its “elder brother” channel 20 is already a solution for massive structures.Obviously, in a private house there simply will not be places where such a design can be used, except for the construction of some kind of exotic foundation for a dwelling. The main scope for a 20 cm profile is loaded structures or mobile structures. As an example, various types of cranes or mobile platforms can be cited.

The channel 20 is made in the same way as number 12, however, it must be remembered that it can be designated as “No. 20” and 200x80x5, where 200 is the height of the wall, 80 is the width of the shelves, and 5 is the thickness of the steel sheet. In the case when a product is required, the surface of the shelves of which will be inclined, instead of the thickness of the metal, a certain average value of the thickness of the shelves t is used. Most often, the channel 20 is made of steel grade 09GS2S, the density of which is 7850 units, and the chemical composition allows you to work at temperatures from -70 to more than 400 C.

Profiles 8 and 14 mm.

To create various designs where high strength, but relatively low weight is required, another type of profile is used - channel 14. Its main advantage is that due to its shape and thickness of the metal it is able to withstand heavy loads, and therefore does not require the use of additional reinforcing elements . High strength profile perfectly complements its low weight.

The mass of the profile depends on which channel 14 is required. If this is a regular equal-shelf profile, then it is minimal. With the increase of one of the shelves, the weight of the product will increase, and when it comes to the inclined faces of the walls, it will be the greatest. I must say that strength will increase more than substantially.

Channel 14 is used not only in construction, but also in the creation of various engineering structures, as well as in car building. During the construction of residential or office buildings, such a profile is used to enhance rigidity and to make reliable floors between floors.

Channel 8 is available with straight shelves and with inclined inner edges. The manufacturing technology of such profiles involves the use of a rolling mill or roll forming equipment. Accordingly, in the first case, the product is governed by GOST 8240, however, there are other standards, for example, that apply to special products, such as channel 8 for the needs of the automotive industry.

As raw materials for the production of these profiles can be used cold-rolled or hot-rolled steel, as well as carbon, structural or low alloy. During construction, channel 8 is in demand for the creation of long-span trusses, ceilings and other similar structures.

Perforated Profiles

To solve complex problems and create complex structures, special metal structures can be used, for example, channel 18, but there are a number of applications where they will not be the best solution. We are talking about laying engineering communications, which usually cannot boast of tremendous weight. In such cases, on the contrary, it is required to provide a sufficiently high strength, combined with invisibility. For example, the same channel 24, which can withstand very large weights, is too bulky, and its own weight, to put it mildly, is large.

Engineering communications are installed using perforated profiles. Such products are made of steel, but their strength is not too high due to the presence of perforation.

Perforation, which reduces the strength characteristics of the profile, makes it possible to obtain a huge advantage in another area. Channel 5, having a special design, can greatly increase the installation speed of various equipment without the use of welding. Special nuts and bolted connections make operation simple and minimize labor costs.

The low strength is also due to the fact that initially such profiles are designed specifically for the installation of various communications or for finishing work. It is obvious that the channel 18, created for the installation of various structures or to strengthen any structural elements, already at the design stage is significantly different from those products that will have to withstand only relatively small weights.

I must say that in the general case, the following types of perforated profiles can be distinguished: galvanized and painted. Channel 6 galvanized is most often used in rooms or where contact with water drops, abrasive compounds or high humidity is practically excluded. This is due to the fact that this type of coating is not designed to work in such conditions, which means that there is a risk of damage and the metal will begin to break down.

As a compromise solution, they often use the channel 100 aluminum. In this case, we are talking about a 100-mm wall connecting the profiles. Aluminum is attractive for use in various external wall coverings in that it can withstand the effects of water, light, air and is not afraid of abrasion. Of course, the payment for such a high resistance is the lower strength of such products, so the channel 30 is usually not made of aluminum.

The second option for protecting the perfume channel is the use of powder paints. In one of our articles, we have already considered this issue, so we will not dwell on it in detail. It should only be noted that such protection can be used in conditions of high humidity and will adequately tolerate contact with drops or steam.

The dimensions of the perforated profile are determined by the task set for architects or designers. Usually, those solutions that are already developed and successfully applied in practice are used. This is another reason why no one is in a hurry to release the 16 perforated channel, because there is practically nowhere to use it. Of course, such a product is suitable as a tray for laying communications, but this niche is already occupied by cable channels and special trays. The most popular options are a profile from 32x20 to 80x40, having 1 or 3 perforated sides.

Above we examined almost the entire range of profiles, so now you should not have to ask the question "Where is channel 18 used?". Of course, we did not list all the possible applications, since many of them are highly specialized. The same channel 40 is characterized by maximum rigidity and the main scope of its application is shipbuilding and the creation of offshore platforms. It is worth saying that all sizes of profiles can be considered from the point of view of breakdown by type. In this case, it is divided into special, inclined, economical and light, as well as products having parallel sides of the shelves, for example, a channel 22 P.

Alas, no comments yet. Be the first!