Many buildings are built using a variety of materials, however, one of the main problems is to achieve the required strength and performance characteristics with a relatively low material consumption. In such situations, structures are reinforced with special elements, the most common of which is a hot-rolled steel channel. Often it acts as a skeleton of a building, because what can be stronger than a profile made of good steel?

Of course, construction is not the only area where the channel is in demand. Areas such as automobile or car building also need strong, light and durable metal structures, allowing you to create a reliable frame for equipment. The creation of large vessels and offshore platforms also cannot do without such an element as a steel channel. Usually, special solutions are used for these purposes, for example, a 400-mm profile, which is durable and very well resists most various loads.

Despite the fact that the channel is used in many areas of human activity, information on such products is contained mainly in specialized publications. Of course, a professional will be able to find it quickly, but a layman will only come across offers to purchase a steel channel at a bargain price. Knowing this, we decided to summarize some of the information in this article to facilitate the work of those who will be engaged in the search for similar information.

What is a steel channel

In order to answer this question, you must first of all consider the method of manufacturing such products. There are only two of them, and the first involves the use of a rolling mill.

Rolled metal is of several types: shaped, long and sheet. The channel is shaped steel, which in turn can be divided into thick and thin. The first category includes products whose thickness is less than 4 mm, and the second - which are thicker than 4 mm.

You can often hear that the channel is cold-rolled and hot-rolled. This is not entirely true, since in the first case we are talking about a bent profile. It is made using special roll forming equipment and can be plain or perforated. Manufacturing technology, features and characteristics that distinguish such a metal channel are given in our article devoted to this topic.

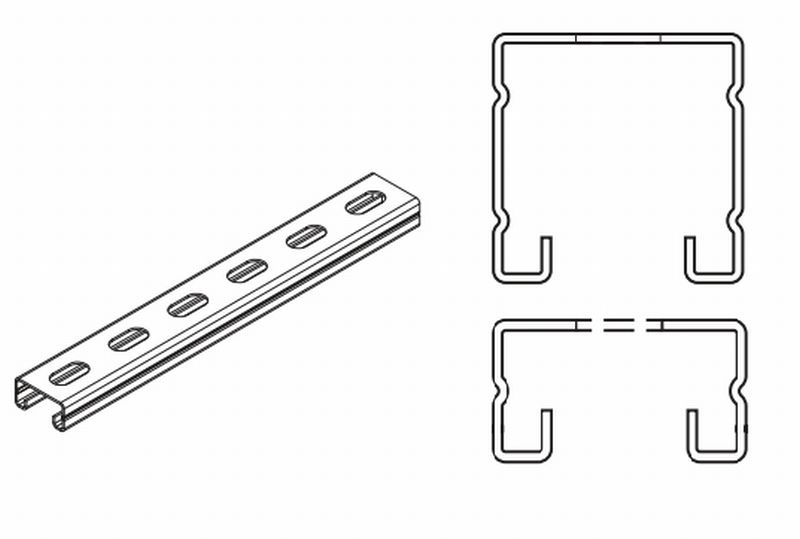

It is easy to distinguish a hot-rolled profile from a bent one: they have different shapes of faces, and the first one looks more massive in cross section. Typically, a channel is distinguished by a U-shaped section, however, it must be clarified that there are variations on this topic. As an example, consider a perforated channel. Such products cannot boast of very high strength, but they have another important feature - low weight. Due to the proper perforation, the steel channel has sufficient strength for laying communications.

Perforation itself can go on one side, or on the entire surface of the product. We also note that such a channel is made of thin sheet steel, and can be not only P-, but also C-shaped. In the second case, we are talking about a special development designed for use with a channel nut. The steel channel with perforation is ideal when quick installation without welding is required.The nut is fixed due to the curved side walls of the profile, so the channel can be used for quick installation with a minimum number of working hands.

Typically, a perforated type of profile is made on roll forming equipment, but the classic options are produced in two ways. To work with heavy loads, it is recommended to use a hot-rolled steel channel, since it slightly exceeds the bent profile in terms of strength and reliability.

The modern classification according to GOST involves the division of all channels into several categories:

- hot rolled;

- bent.

The first, in turn, are divided into those that have shelves located in parallel, and with inclined inner faces of the shelves. A bent steel channel, the weight of 1 meter of which is significantly lower, can be equally or unequal. In the process of creating such metal structures, various types of steel are used. We have already considered this issue in an article where a list of factors affecting the weight that a hot-rolled steel channel has is given, so we will not dwell on the types of steels in more detail.

How to choose the right channel

In this case, as in most other situations, the task is to determine the ideal option for your case: the channel is hot-rolled or bent, equal-shelf or having unequal shelves, perforated or made of aluminum. All these products are specialized and best reveal their properties in a particular case. If you use a steel channel is supposed to strengthen the balcony, then the distance between its walls should correspond to the thickness of the plate.

Moreover, the thickness of the product itself is selected so as to ensure high reliability of the design and must be verified by appropriate calculations.

In order to choose solutions to any structural problems, it is best to turn to a ready-made project or involve a specialist who can analyze a huge number of factors influencing a metal element and correctly calculate the load. The channel can also be economical, which indicates a relatively small thickness of the metal.

The low strength of the economical class of profiles is due to the small thickness; therefore, such a metal channel channel is undesirable for critical structures or those areas where a rather large load on the structure is expected.

There are specialized varieties of profiles, but in order to use a steel channel of this type, it is necessary to evaluate the change in mass of the future design, since such products can have a very large weight. Excessive weighting of the building frame will not lead to anything good, therefore it is often recommended to stop the choice not on carbon but on alloy steel.

If you want to hide communications, then using the channel will be quite appropriate. Usually, in such cases, it is not bent, but rolled. An economical steel channel is suitable for the role of a support for communications.

As an example, we compare the characteristics of a classic and special profile with a width of 180 mm, the shelf height of which is 70 cm. In the first channel is made of steel, the thickness of which is only 5.1 mm, but for the needs of the automotive industry another product is produced having a thickness of 9 mm.

A metal channel for repair or construction work can be anything, but you need to remember that its parameters should be taken into account when calculating the project.

Why bad hot-rolled channel

A massive metal profile with all its advantages is not without certain drawbacks, for example, it has a sufficiently large mass. If we compare it with aluminum, then the hot-rolled channel by mass has a 3-fold superiority.

The second problem is that steel requires protection from harmful influences. Metal is afraid of water and moisture, therefore galvanizing is used or it is painted. The perforated channel, which is most often used in difficult conditions, is protected with powder paint, which we have already described in detail in one of our articles.

The designation of a bent equal-channel channel depends on its type and in most cases looks like a wall width: shelf height: metal thickness or h: b: s, respectively.

Summing up, it should be noted that here we examined all the advantages and disadvantages that distinguish a hot-rolled channel, and also described its properties and features. Some of the points were not covered in such detail, as we already talked about them in other articles on the topic of "Channel".

Alas, no comments yet. Be the first!