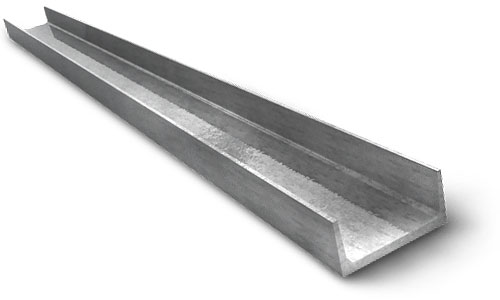

This is a type of metal that has a U-shaped cross section. Such a structure is formed from a wall and two shelves. Modern construction is unthinkable without such elements, which with relatively low weight can easily withstand significant loads. If you need a channel, the dimensions of which must be strictly defined, then you need to remember that there are equal and unequal products. In the second case, the sizes of the shelves forming a U-shaped section will be different.

In construction, the following types of channels are used:

- having an internal slope of the shelves;

- with parallel inner faces;

- bent equal and unequal;

- special;

- cold rolled.

Product designation

To simplify the selection of the right product, the distance between the shelves is used. This is the figure after the designation of the element, but there are also differences in length: it varies from 4 to 12 meters.

From the point of view of counteracting large loads directed vertically downward, the channel is second only to an I-section beam. The width of the shelves varies and starts from 32 mm, and can reach 115 mm, so the load capacity varies widely. A similar situation is with the height, which happens from 5 to 40 cm.

It must be remembered that the standard channel 10, the dimensions of which can be different, will be the section that is required in a particular case and depends on the place of application. The letter after the number showing the distance between the shelves will tell the specialist about the type of product. If you use a product with an index of "U", then we are talking about inclined internal faces. When the shelves are parallel, then this is a channel of the "P" series. There are also “L” - light, “C” - light variety.

The use of channels

Today, the demand for such products is high enough, due to the widespread use of concrete and metal structures. The attractiveness of the channel lies in the fact that it has a low weight, and can withstand quite a significant load. The channel is obliged by this feature to its U-shaped profile, which provides the necessary combination of structural properties and reliability. Metal structures of this type can be used for both construction and repair work. They are used in a wide variety of fields, from mechanical engineering to the creation of various shelving units.

Various metal structures that are being erected for advertising purposes or for laying communications are also the place where such elements are in demand. Channel 20, the dimensions of which vary widely, is great for this purpose.

The type of metal depends on where the metal structure will be used. For example, to work under heavy load it is better to use a design that has inclined shelves. In fact, the outer contour of the product still remains U-shaped, however, the inner one already has some deviations from this shape, because the inclination of the inner walls can be large. Due to this, increased wall thickness and higher reliability are achieved.

The type of channel and its parameters are selected only after calculations, and they must be performed by a specialist. Otherwise, problems may arise due to improper choice of thickness or other characteristics of the product, which means that the reliability of the structure will decrease.

Aluminum channel

The classic U-shaped structure made of steel has not only great resistance to bending, but also resists torsion deformation, so the scope of such products is very wide. The use of aluminum has further increased the area where these metal structures are used today.

Channel 16, the dimensions of which are ideally suited for those structures that experience light loads, are used no less than its steel variety. Aluminum structures are well suited for applications where environmental contact is required. Aluminum itself compares favorably with steel in that it does not interact with air or water, and therefore the reliability of the future structure does not depend on such random factors as bad weather or improper maintenance of painted elements.

In general, an aluminum channel is much more profitable than a profile pipe of the same size, since it can further reduce the weight of the future design.

In conclusion, we note that one of the main advantages of most types of channels is the ability to build metal structures without the use of welding. This allows you to create collapsible structures that can be moved to another location in whole or in part. For example, this technology is used to create a variety of seasonal structures, temporary buildings or warehouses. The channel, the dimensions of which are proportional to its weight, is a modern building material that is in no hurry to hand over its positions to plastic or concrete.

Alas, no comments yet. Be the first!