In Russia, a slate roof is a widespread phenomenon, although in Europe the production of asbestos-cement slate sheets was actually banned due to their carcinogenicity. But over time, technology has improved, and now fearing a good slate is no longer worth it. This article will talk about the features of slate, its use, we will not forget about slate nails.

Content

So what is slate?

Natural slate is a tile obtained by splitting clay shales. Natural slate is rightly considered one of the most ancient building materials. Roofing slate tiles were used in the Middle Ages, and some of those buildings have survived to this day!

At the moment, real slate as a roofing material is used extremely rarely, and asbestos-cement sheets are now called slate.

After and other roofing materials with a shape in the form of wavy sheets began to be called slate. So, there are asbestos-free slate, euro slate (corrugated sheets from bytum), metal slate (corrugated metal sheets).

Asbestos-cement slate is an inexpensive and easy to install material. is he cheaper tiles and tin at times. It is very important that such a slate has low thermal conductivity, high frost resistance, resistance to adverse environmental influences, and is fireproof.

The following modifications of asbestos-cement slate exist:

- wavy slate with an ordinary profile (VO). Sheets of regular rectangular shape;

- wavy slate with a reinforced profile (WU). Suitable for the construction of industrial facilities;

- wavy slate with a uniform profile (HC). The dimensions of the sheet are larger than VO, but smaller than VU. Due to this, the number of joints is reduced by almost half.

Some features of using slate

Slate roofing should be accompanied by constant attention to the smoothness of the outside of the slate sheet.

Slate is laid like this:

- slate sheets are stacked from right to left in the transverse direction, so as to ensure that one of the sheets overlaps in a single wave;

- in the longitudinal direction, the slate should be placed from bottom to top, watching for the overlap of the row laid below the top sheets (14 cm).

DIY slate painting can be done after laying the slate using one of the proposed methods:

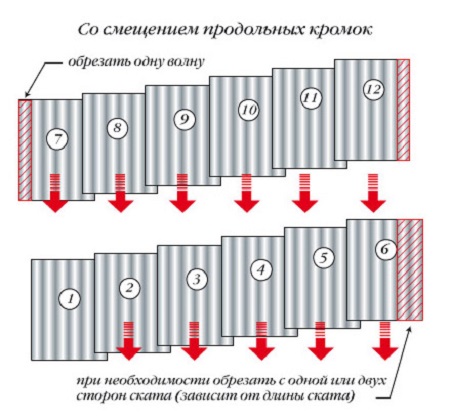

- with a shift of the longitudinal edges of the slate by one wave relative to the sheets below (you will need to trim a certain number of sheets by 1-3 waves);

- with the combination of the longitudinal edges of all sheets located below (it will be necessary to cut the corners of the sheets to ensure straightness of the lines of joints).

Slate roof: creating a crate

Before proceeding with the installation of slate, the roof must be prepared by creating a reliable, strong base on it. The best base for installing asbestos cement is a crate made of wooden beams with a cross section of 6 by 6 cm.

The bars are laid out so that they have an alternation in height: the odd ones have a height of 60 mm, the even ones have a height of 63 mm. Since all our bars are of the same size, even ones will have to be increased with wooden planks with a thickness of 3 mm. Due to this, we will ensure the density of the longitudinal overlap of the slate.

The battens of the crates are laid out and fastened usually with a step of 53 cm, starting from the eaves to the ridge.They are fastened with screws, nails and anti-wind brackets.

The dimensions of the lathing are designed to ensure the laying of an integer number of slate sheets in both transverse and longitudinal directions.

If it is impossible to observe the above principle, the penultimate sheets located in the transverse rows are cut off near the gable overhang, and in the longitudinal direction the sheets are cut off near the ridge.

The beginning of the installation of slate roofs

Before proceeding with the installation of asbestos-cement sheets in place, they are checked for damage or defects, as well as for compliance with the declared dimensions, then the corners or longitudinal strips of the sheets are trimmed.

Roofing is carried out as follows (so is a single-pitched slate roof, and any other):

- each sheet is individually lifted to the roof and fixed (slate nails will help in this), starting from the right side of the lower boundary of the roof slope. Rows overlap;

- holes for fastenings are drilled with a manual or electric drill. Their diameter should be 2 mm larger than that of the fasteners (screws, slate nails or other fasteners - there is one rule);

- nails should have a metal or rubber washer, which should be coated on all sides with linseed oil. Then they are inserted into the prepared holes and clogged with a hammer;

For fastening, it is optimal to use slate nails with a combined head and dimensions of 4 by 10 cm, the diameter of the washer is 18 mm. Drive the nail in until excess grease comes out from under the washer.

- after drying oil, nail heads are smeared, and on top, after complete drying, they are painted over in the color of slate sheets.

Arrangement of a ridge for a slate roof

The slate roof determines the accurate and attentive implementation of the roofing ridge device. It is necessary to place a wooden beam on the ridge, and on both sides of it along the entire length, attach two battens.

After both slopes are covered with slate, brackets are mounted on a wooden beam mounted on a ridge, and portable portable bridges and a ridge beam are attached to them.

Before covering the roof with a ridge roof, the upper edge of the installed bar is rounded off according to the radius of the ridge slate. The bar along the entire length is covered with rolled material, and now it is already possible to start laying the ridge slate.

If you lay the slate on the roof with one slope, it’s even easier for you. Here, the ridge is placed to the pediment with the side of a wide bell and covered with a second ridge.

Next, marking is made for the mounting holes. After that, both skates are drilled along the longitudinal axis, and I also make holes on the tops of each of the skates (they must pass through the crests of the wave at the slate sheets of the main coating).

The roof slope, which is adjacent to the edge, must be covered with spacers - these are the oblique parts of the sheets with the dimensions determined at the installation site. They are laid very tightly to the edge beam and mounted on the crate in the same way as ordinary sheets - with screws or slate nails.

On the edges of the crate, a tape of roll material with a width of 35 cm is strengthened, after which the skates are laid in pairs from the bottom up. They are strengthened in the same way as on the skate itself.

Slate roof painting

Covering the roof with slate is often not enough. Immediately after the installation of the slate roof is completed, you need to think about painting the coating.

Everyone knows that most often asbestos-cement slate is produced in gray (although now the color gamut has noticeably expanded).

To decorate the roof, as well as significantly increase the life of the slate coating, the sheets are stained with acrylic paint, which is very resistant to any weather conditions.

After you apply acrylic paint, a special protective layer forms on the roof, which will resist the destruction and absorption of water by the material, moreover, we usually increase the frost resistance by the method of painting. The paint protects the slate coating from the appearance of moss and lichens on it.

Slate roof repair

During long-term operation of the slate roof, chips or cracks may appear on the material, which can lead to leakage of the roof during precipitation.

In this case, repairs must be carried out immediately. The easiest way is to putty the individual cracks that have appeared.

To begin with, you need to make a special putty solution using drying oil and chalk. All defective places must be thoroughly greased with a putty, then apply bitumen mastic to the cracks, and after drying it should be painted over with any oil paint. This method is good for minor damage.

If a large area of the roof has flaws, it is best to make fabric patches, and before installing them, first clean and prime the damage site with drying oil. To glue patches, it is best to apply oil-based, thick-grated paint. The size of the patch should be slightly larger than the dimensions of the destroyed area (about 10-15 cm), and the staining area should exceed the size of the patch by about 2-3 centimeters.

To repair holes in slate, use a cement mortar prepared in a ratio of 1: 1 with sand. The solution needs to be smoothed, primed, and then wait for complete drying and color.

If the roof has already begun to leak, replace the damaged slate element with a new one as soon as possible. To remove the damaged sheet, the fastenings of the surrounding roof elements are loosened using partial nail removal.

Slate nails are completely removed from the damaged element with a nail clipper, after which the entire sheet is removed.

When installing a new canvas, one of the builders should slightly lift the weakened elements to the side and top of the installation site, and the second at this time should lay a new sheet along the edge of the sheet located on the side. After that, the sheet is shifted towards the ridge under the sheet, placed on top of it.

After the sheet occupies the desired position (in which the replaced element was previously located), it is securely fastened, and then the loose fasteners are returned to their original place, and the direct repair of the roof can already be completed.

Slate roofing - the material is popular, but before you choose it on it, you should carefully weigh all its pros and cons. Low cost, low weight, ease of installation attracts developers, but don’t rush into the pool - compare all possible roofing options.

Alas, no comments yet. Be the first!