The construction of a solid residential building is not an easy task. Facing the external facade gives the building completeness and beauty, but the foundation of the building needs the most reliable protection. Regardless of on what basis the structure was erected (on screw piles or strip foundations), it must be strengthened so that it serves for many years. Sheathe the foundation of the house from the outside with different materials. Not all of them have a high cost. Decking is cheap, and if you apply ingenuity and skill, you get a good external protection. Also, the base is finished with bricks, polymeric materials, composites, brick or clinker masonry.

Content

Sheathing with corrugated board and its features

For external insulation of the base of the house, corrugated board is often used. It prevents the penetration of cold into the building, protects the foundation from the effects of winds and rains. From the point of view of beauty, such lining looks simple and straightforward, but in the absence of opportunities, it will help out the owner of the house and save him from premature destruction. As a frame for such sheathing, wooden bars are used, and the sheets are fixed with dowels or metal rivets.

It is better to order sheets with the right height right away. If the measurements are accurate, the master can do without fitting and save time.

For beauty, you can order corrugated board with patterns made "imitation wood" or "imitation natural stone." Such a finish looks beautiful, but its price will be twice as high as sheets painted in one color. In the photo and video to the articles on construction and decorating, you can find many beautiful examples of such finishes.

The choice of metal sheet

It is not difficult to sheathe the foundation with professional flooring with your own hands. Most often, sheets with the marking C are used for this, which means "wall corrugated board". The wavelength of the sheets is different, depending on the scope of their use. It is from 8 to 21 mm. From several types of such material, you can choose the following:

- simple option, without protective coatings. It will need to be periodically painted. For decoration of private houses it is rarely bought;

- hot dip galvanized sheets. Of these, temporary fences are made at construction sites. It is better not to use them for facing;

- metal profile with a protective coating of polymers. It is applied either to the outside of the sheets, or to both surfaces. If you decide to finish the base of the house inexpensively, you can use this option;

- embossed corrugated board with texture. It is used not only for protection, but also for decorative purposes.

The technology of embossing and coating with polymer compositions is used only on galvanized profiled sheets. They have high strength, and use different polymeric materials as a coating: from acrylate to polyurethane.

If you live on a site with strong winds, you will need a professional sheet with markings from C8 to C10.If a lot of snow falls in the winter, a low-wave corrugated board will not be enough: it can deform under the weight of precipitation. In such conditions, the lining is made with a profile marked from C13 to C21.

Frame basis preparation

Before sheathing the foundation of a house with a professional sheet, the following should be considered:

- install sheets only vertically;

- fasten profile runs horizontally;

- basement, protruding above, protect by low tide;

- fix the tide with brackets. Most often they are attached to the ventilation crate;

- if there are “underground” sides, leave openings for ventilation. Their size should be approximately 1/400 of the total floor area on the floor;

- frame products with low tides or metal corners.

The installation of the crate should begin with marking. For vertical cladding run size should be from 0.7 to 0.85 m. Place suspensions at intervals of 0.5 to 0.8 m, and fasten the plumb screws with screws. The run profile must also be attached to the suspensions with dowels and joined with metal corners. The extension of the profile in length is done using direct connectors.

The ventilation crate is made of 4 equal parts of the corrugated board, taking into account the perimeter of the hole. To mount each element, you need to take two suspensions. As for the waterproofing of concrete and the insulation of the base, these works should be carried out before the start of marking.

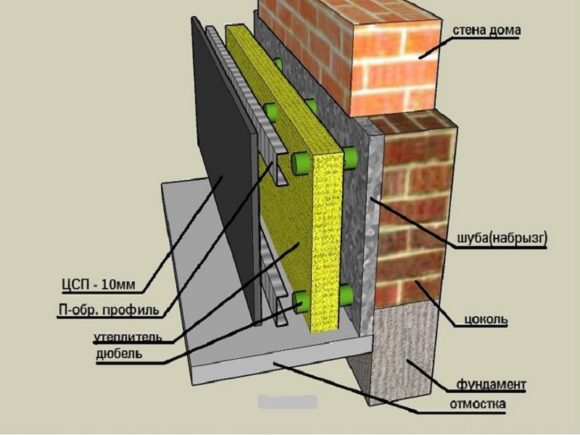

Insulation and insulation works

The foundation must be insulated and insulated from moisture. Waterproofing is:

- okleechnoy;

- smear;

- plastering.

The waterproofing layer is applied to the entire area of the concrete base. Thermal insulation should be done, adhering to a certain scheme. To do this, the entire surface vertically and the face located horizontally at the top are glued with a material that retains cold. As a rule, it is cotton wool from basalt or expanded polystyrene.

The place where the blind area adjoins close to the base must also be sealed. To do this, on one of the runs (bottom or top) a film or a layer of hydroglass is fixed. The layer is fixed directly to the laid insulation. If you use basalt or glass wool, do not forget to cover it from the outside with a vapor barrier film. This will prevent premature drying of the material - especially if there are ventilation openings nearby.

How can you fix corrugated board

For the manufacture of runs apply different types of material. The following types of fittings are suitable for attaching the profiled sheet to the girders:

- dowels or screws. They are universal: with their help they fix the material on different profiles (Z and P);

- rivets. They are intended only for fixing to a metal base.

If you choose dowels, you need to consider that over time they become weaker. This is influenced by weather conditions and mechanical stress. The advantage of using self-tapping screws is that the lining can be repaired at any time. Rivets "tightly" grow into metal, which greatly complicates their removal if it is necessary to replace the casing.

Do-it-yourself cladding of the building with a professional sheet from one of the corners. Installation of sheets is done with an overlap of one wave to another. You can only cut corrugated board with an electric jigsaw. The grinder is not suitable for this purpose: while working with it, all metals are heated to a critical temperature and the protective coating is melted. If you do not have a jigsaw, use scissors for cutting metal or a drill with special nozzles.

Installation of ventilation holes and final steps

When installing professional sheets, do not forget to cut the ventilation holes in the right places. All openings are closed with plastic grilles after complete sheathing of the foundation. Lattices are fixed with dowels to the frame structure.

After complete sheathing of the pile or other foundation with your own hands, you need to install the elements of the extension. They protect the lining from moisture.

At the final stage, additional elements are installed that will prevent atmospheric moisture from entering under the facing material. The tide must be installed on the upper frame profile, and fixed with rivets and dowels. Low tide contributes to the removal of water, which will drain from the walls of the house facade. The element must match the color of the entire basement casing. In conclusion, the structure is reinforced with outer and upper corners. This must be done to seal the corners of the building so that moisture does not get inside. You can choose a different color for covering the corners, which will be in harmony with the overall picture.

Finishing the basement with other building materials

In addition to corrugated board, there are many other materials that trim the socles. All types of cladding can be bought at a large construction supermarket. The cost of most of them will be an order of magnitude higher than metal profiles. Installation will also require more time, but the lining will be not only solid, but also beautiful. As in the case of the metal profile, when working with other building materials, several important nuances must be taken into account:

- the upper part of the base, protruding above the facade, must be protected with the help of ebbs;

- the smallest material is tile. There are flexible types of tiles with which concrete surfaces are lined;

- if you make brickwork, the house will become wider;

- frames for fastening the casing must be insulated from the inside. This will help prevent heat loss from above and below;

- it is better to use frame systems for fastening the skin. They are easy to install, they can be repaired, updated and repaired at any time.

The decoration of the protruding base is carried out before facing work. Often there is a need to hide one of the fastening shelves of the tide under the walls.

Brickwork

Brick laying of the basement begins with laying the base. If you have a site with heaving soils, you will have to remove the topsoil. The thickness of the layer is about 40 cm. After removal, the top layer is replaced with sand or gravel and rammed into several layers.

Concrete has better thermal insulation properties than brick. This must be considered when laying. A waterproofing material is laid on top of the litter. One layer will not be enough: it is better to lay two or three at once. To prevent brickwork from masonry, a rigid ligament technique is used. A rigid ligament with a base is made in this way:

- stack 2 or 3 rows of bricks;

- several blind holes are carefully made in the carrier base. The depth of each of them should be from 4 to 6 cm;

- fittings (6-10 mm) are inserted into the holes to connect the main wall with the cladding.

For work, it is better to use ceramic bricks, as well as hollow or slotted stones. There are several extruded modifications that have high strength and resistance to environmental factors. As a heater, between the brick cladding and the base, you can lay basalt cotton wool or any polystyrene-based material.

Clinker tile application

The cost of clinker tiles is not inferior to brick. However, compared with brickwork, this tile has several advantages:

- high resistance to environmental conditions;

- it is a leader in terms of operation, not only in comparison with brick, but also with other types of building materials;

- it is produced with finished corner structures;

- it is easy to mount to the wall;

- it does not need a separate base for fastening;

- the clinker weighs little, so the load on the load-bearing elements of the building will be minimal;

- The tile looks very beautiful.

Clinker successfully imitates not only brickwork, but also natural stones. If your house has a unique architectural style, choose a clinker for facing the foundation. It will organically fit into the original atmosphere of any home. When laying the tile is “planted” on the glue, and the panels are fixed on the frame.

Sand tile

Polymer sand tile is a polymer-based composite material. The shape of such tiles can be different. It is lightweight, does not overload load-bearing structures, but fix it on a frame or glue intended for polymers. Imitation of masonry or natural stone is very successful. At a superficial glance, it seems that your home is finished with expensive material.

The advantages of polymer sandstone are as follows:

- resistance to moisture;

- low coefficient of expansion;

- resistance to direct sunlight (siding does not fade for a long time);

- It is resistant to mechanical stress;

- it is easy to cut: a manual hacksaw is enough for cutting;

- the material can be given any shape and reduce its consumption.

The only subtlety that needs to be considered is the lack of additional elements. When working, the master must precisely adjust the corners and all the places of contact.

Work with a natural stone

There are regions in which you can buy natural stone for a moderate fee. Natural material is used for those buildings in which they do not plan to live all year. This is the heaviest type of cladding, which will not be supported by heat-insulating gaskets. Most commonly used:

- dolomite;

- granite;

- gravel of different fractions.

They are durable and barely leak moisture, but because of the many seams that remain after installation, grouts must be used to waterproof the joints. This cladding is not repairable.

Artificial stone finish

For finishing work most often use concrete slabs with a decorative texture on the outside. To increase the resistance of artificial stone, moisture resistant compounds are used. In order to preserve the decorativeness of the outer layer, it can be additionally painted. Fasten the material to glue, but only after the foundation has been primed. Artificial cladding is universal: it is suitable for any facade.

What to choose: porcelain tiles or tiles

Before using tiles or porcelain tiles, the entire area for cladding must be made even. Glue is applied with a layer of not more than 1 cm. Both materials are intended only for exterior decoration. Tiles have a wide selection of patterns and colors, but porcelain stoneware is stronger. The load on the foundation is small, and the grouting of joints is done with moisture resistant compounds.

When using tiles, additional waterproofing of the surface is necessary in the form of processing the foundation with a primer or mastic from bitumen.

Putty or plaster

Plaster or putty is more often used to smooth the surface before finishing. They need to be protected from moisture by painting with a water-based emulsion. In addition to paints based on an aqueous emulsion for decoration, apply:

- dispersed dyes;

- acrylic;

- acrylates;

- oil paints.

Putty and plaster are used for finishing wet facades. They fit well on rebar, polystyrene foam and basalt cotton wool.

Using basement siding

You can sheathe the foundation of the house with basement siding. It consists of vinyl, lightweight, and its cost is low. Despite the lightness and specificity of the material, the siding is well suited for one-piece cladding of the external facade of a simple house. The material successfully imitates wood, brickwork, artificial stone. It looks beautiful, and fasten it to glue for vinyl panels. The panels are equipped with locks, which they need to be connected to each other during installation. The material is designed to be mounted on a frame crate, therefore, an insulation layer is laid between it and the frame to reduce heat loss.

Covering the foundation with flexible tiles

Flexible tile is designed for roof cladding. This is its intended use, but sometimes it covers the foundations of buildings. A prerequisite for working with it is a perfectly flat surface of the foundation. Since the material is very thin and flexible, after installation, all errors and irregularities will be visible.Despite this drawback, for a columnar or pile foundation, such a tile is one of the best lining options.

The crate is stuffed vertically on the supporting parts of the structure. Instead of the crate, you can install the runs and hang on them several asbestos-cement sheets. Everything is pasted over with tiles, fixing it with dowels.

Fiber cement panels

These are composite materials with a long service life - from 20 to 30 years. They are made by hot pressing. As raw materials, wood fiber and cement are used. Surfaces from the outside are laminated or coated with a layer of protective compound. Like other composites, fiber cement panels well imitate the color and texture of different types of trees, stones and brickwork.

Fiber cement is resistant to weather and sudden changes in temperature, beautiful, but most importantly, street dirt does not stick to it. It cleans itself spontaneously, and residual dirt and dust can be easily removed with a stream of water from the hose. The panels are equipped with locks with gaskets - for durability and tightness of the finish.

Sheathing the foundation of the house can be done not only with corrugated board, but also with other materials. If you have the skills to work with corrugated board, brick and different types of tiles, you can permanently keep the foundation of your home.

Alas, no comments yet. Be the first!