In the construction of roofs, metal is used not so long ago. However, this roofing material has already established itself as strong and reliable. The main types of metal and how to cut metal will be discussed in this article.

So, what is a metal tile? These are sheets from aluzinc and galvanized steel. The profiled method of rental allows you to create the correct geometric shape of the product. Special layers take on not only decorative functions, but also protection from environmental influences.

Content

Metal: parameters and classification

- light weight;

- easy installation;

- long service life;

- attractive view.

The main classification of metal.

The metal tile is divided according to the following parameters:

- color;

- polymer coating;

- profile form.

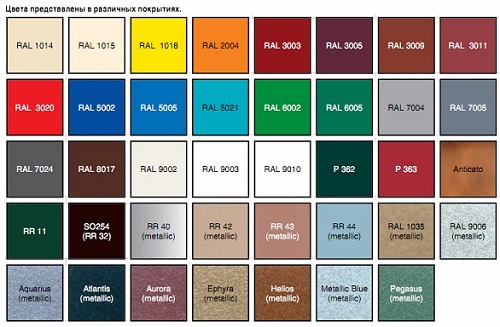

Metal: colors used for painting

When painting, all metal manufacturers use the RR and RAL scales. As a rule, preference is given to natural colors: chocolate, red wine, graphite, green foliage, green moss. More rare are bright and saturated shades of red, blue, green. Do not ignore the fact that dark colors in the sun fade faster. High-quality metal tiles are characterized in that the paint layer lasts much longer and fades evenly. However, unfortunately, you can only find out about how high-quality roof you have acquired in a few years. That is why it is advisable to choose building materials from well-known companies where the production of metal tiles is subject to all technical rules.

What is covered with metal?

Types of metal tiles are determined by the coating and its properties.

- Polyester. This coating is based on polyester paint. It has good durability, suitable for use in any climate. It can be applied to tiles in two versions: matte and glossy. The advantage of this coating is also that it is quite inexpensive. Glossy polyester is applied with a layer of 25 microns, and matte 35 microns. Despite the fact that the glossy version of the paint has a more attractive appearance, is more durable and color fast, all the same, consider the matte finish. The service life of this type of metal tile can be up to 40 years;

- Pural. This type of coating is polyurethane, polyamide and a special dye. Due to the structured composition of the pural, the tile has high parameters of resistance to ultraviolet radiation, mechanical damage, and environmental influences. The material is able to withstand temperatures from -45 to 120 ° C. In addition, in this case, if necessary, repair painting of tiles is possible. Layer thickness 50 microns;

- Plastisol. In fact, this is a plasticizer consisting of special grades of polymers, or rather their dispersion. Plastisol is applied to the tile by spraying. The result is one of the most durable coatings of metal tiles. This substance is made on the basis of polyvinyl chloride. However, for this reason, in some countries, this tile is considered not completely environmentally friendly. Layer thickness 200 microns;

- PVDF (PVF2).The material is highly resistant to corrosion damage and precipitation. It contains pigment, which gives the surface of the tile shine and hardness. However, the service life of metal with this coating is not too long, about 25 years. Layer thickness 25 microns;

- Polyvinyl fluoride (PVF2). This coating has the richest gamut of colors. The material does not exfoliate, has elasticity, and is resistant to both low and high temperatures. It does not fade in the sun and does not change color from precipitation. Metal tiles with a high-quality polyvinyl fluoride coating are somewhat more expensive, by 5-10%, of other tiles. Layer thickness 30 microns;

- P50 (PUR / PrelaqNova / SSAB). It is a type of polyurethane. It has the ability to withstand low and high temperatures. It does not fade under the influence of ultraviolet radiation. It is possible to apply additional layers of paint, for example, in case of need to repair tiles. The thickness of soybean is 50 microns. The weight of the metal tile with this coating is not much more than the previous options, about 6 kg m ?.

The height of the metal

The height of the wave sheet, also determined by the types of metal.

Metal tiles are available in two versions: with small and high wave heights.

A wave height of up to 5 cm is considered small. A fairly common version of the product, used in the construction of various types of buildings. With a rather spectacular decorative appearance, the price is quite reasonable.

A wave height of 5 to 7 cm is considered large. Such a roof is positioned as "elite", respectively, the price is higher than for tiles with a low wave.

Metal: profile shape characteristics

Metal tiles with an asymmetric beveled wave are the most common option.

A metal tile with a symmetric wave is a rarer option. Despite the fact that the cost of such a tile is practically no different from a tile with a symmetrical wave, it is quite difficult to find it on the building materials market. Not many firms produce it.

At first glance, it seems that the difference between symmetric and non-symmetrical waves is not so noticeable. However, when the metal tile is already installed on the roof, the appearance of the entire building, its stylistic features, still differs.

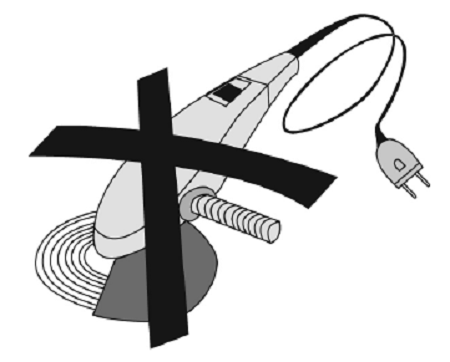

How to cut a metal tile

It is recommended that you use traditional metal cutting tools. Today there are a sufficiently large number of them:

- electric jigsaw;

- manual scissors for metal;

- electric scissors for metal;

- hacksaw;

- electric saw with a disk for cutting metal tiles.

Metal - technical specifications for metal cutting

From what wave height and what metal coating, what to cut a metal tile does not matter. Any of the above tools are used.

However, we draw your attention to the fact that when working with electric cutting devices, safety rules must be followed.

It is also worth noting the ban of most manufacturers on cutting metal - grinder. The reason is that at the point of the cut, the metal heats up to such a temperature that most of the protective layers of the sheet are destroyed. Accordingly, ideal conditions are created for the formation of rust and corrosion at the site of the cut.

Before starting roofing work, carefully study how and what to cut the metal tile the manufacturer offers.

Metal tile production

Everyone who plans to work with metal tiles needs to know the process of its production, which consists of the following steps:

- steel sheet hire;

- coating;

- applying a protective layer;

- profiling;

- packaging.

Let us consider in more detail each of the stages.

All types of metal tiles are made of hot rolled galvanized steel. A special unwinder passes a coil of steel through a lubricating device, and then sends it to a rolling machine. At this stage, quality is determined by the thickness of the metal sheet. As a rule, the production of metal is focused on sheet rolling to a thickness of 0.45 - 0.55 mm.

Thinner metal at the base of tiles, used by Swedish companies. In this case, the weight of the metal tile is slightly less, however, greater accuracy is required during installation and installation.

Russian manufacturers prefer a thicker base, from 0.55mm. Despite the strength, the material has a number of negative qualities. So, for example, it is difficult to mold, some deviations in the configuration are possible, and, therefore, the quality of the joints will not be the best.

Again, the thickness of the metal used does not affect how to cut the metal tile.

The most optimal can be considered a metal sheet thickness of 0.5mm. The material is quite easily formed and has high strength values.

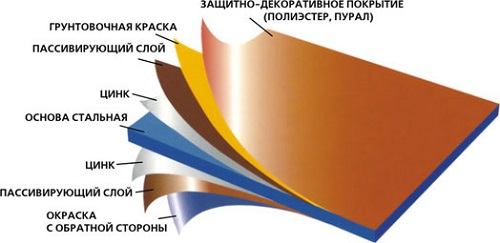

Metal tile coverings

All layers of the coating of the metal assume the protective function of the metal from corrosion. They also protect the material from burnout under the influence of sunlight, give a beautiful appearance.

The operational life of a metal tile depends, first of all, on the quality of the protective coating.

Today, all processes for applying layers to a metal base are automated. Layers are applied in the following order:

- passivation;

- primer;

- polymer coating;

- varnish.

It should be noted that the metal composition is coated with a polymer composition only on the upper side, and a colorless protective coating is applied on the lower side.

After all the protective coatings have been applied, the tile is sent to the molding workshop, where it is given the necessary profile. After forming, the metal is cut into separate sheets and packaged.

Metal tile sheet sizes may have the following: from 0.5 to 6 meters. The most common are metal roofing sheets with a length of 3.5 - 4.5 meters. Since the installation of too long sheets can be accompanied by difficulties with fastening, and fastening of short sheets can be time-consuming. In this case, the width of the sheet is fairly standard, about a meter.

Weight of metal

For a material such as metal tiles, weight 1m? is about 5 kg, depending on the thickness of the metal base and the type of polymer coating.

As you can see, the production of metal is a multi-stage and complex process. In order to get a high-quality product, it is necessary to subject the metal blank to many different technological operations. The result is a strong and durable roofing material.

Alas, no comments yet. Be the first!