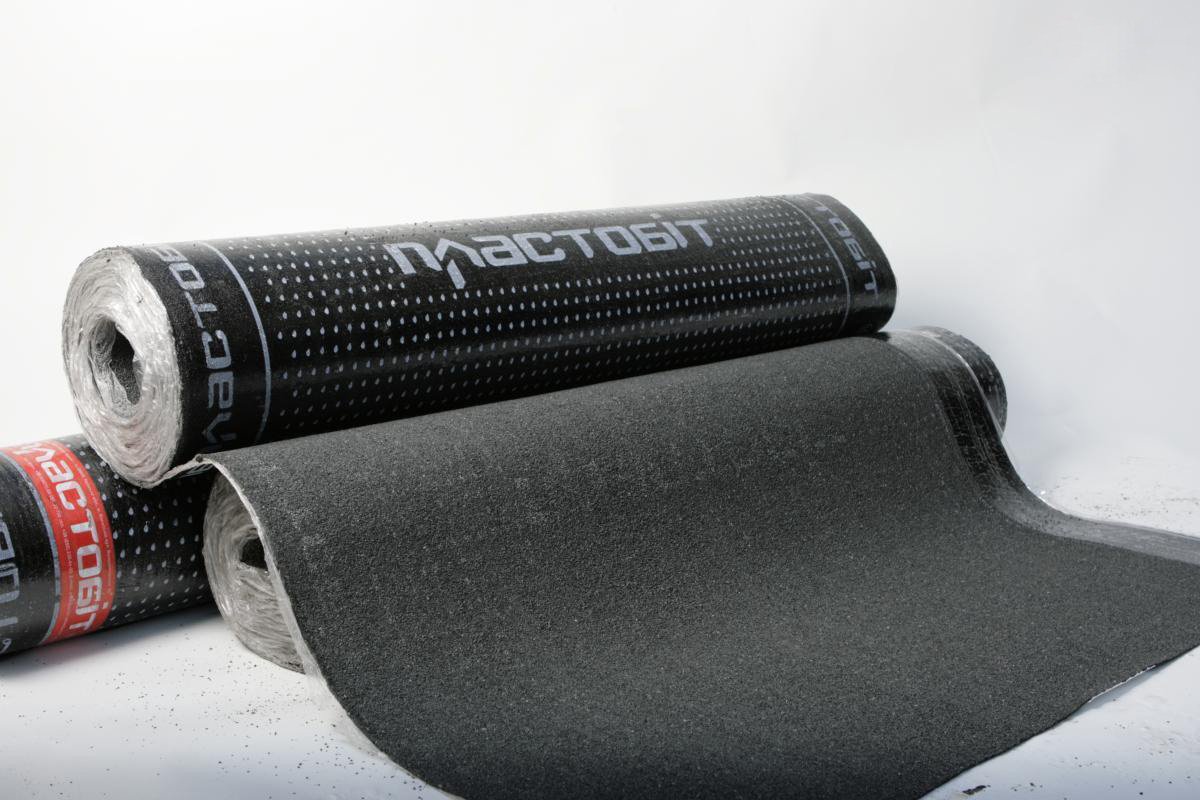

Much depends on what coating is used to protect the roof of the building. First of all, this includes the time of operation of the structure without performing repair work. However, one should not forget about aesthetics and cost, because this is precisely what the rolled roof is attractive.

Content

Field of application of rolled surfaced materials

Rolled materials are excellent for creating roof coatings having an angle of inclination from 0 to 30 degrees. It can be either a single slope surface or a structure with several slopes. The flat roofs of modern buildings, or the sloping roof of a country house can be built using roll materials.

Today, the demand for such coatings is very high, because they have a significantly longer service life than those materials that were available only a decade ago. Only five years could the roof last, and then it required repair. After 10 years, the roofing carpet was already replaced.

Nowadays, the life of such materials reaches 25 years.

What is a built-up roll roof?

As the name implies, this is roll material obtained in two ways. The first is intended for the manufacture of basic coatings and consists in processing the base of cardboard or fiberglass with a binder mixture, which may be tar or bitumen. The second manufacturing method is designed to produce baseless materials. In this case, special methods are used for the heat treatment of cementitious mixtures containing special additives and fillers, after which the resulting mass is rolled into canvases.

All rolled materials can be divided into coverslips, and those that do not have a layer of refractory bitumen reinforced with fillers or additives.

Types of basic roll materials

In this category there are also fairly cheap and indecently expensive coatings, however, the ratio of price and quality (durability) is usually maintained:

- Ruberoid. Roofing material, created on a cardboard basis, was used in Soviet times, however, it is still popular today because it is one of the cheapest coatings. Pergamine is a lining material, which is a special roofing board impregnated with oil bitumen. It is manufactured in accordance with GOST 2697-83. The main disadvantage of glassine and roofing material is their low service life, which is more than worth the small cost.

- Rubemast. This is a built-up roll roof, obtained by technologies similar to roofing material. Such a material has a special protective film that prevents the layers from sticking together and protects the face of rubemast covered with granite chips from abrasion. The service life in this case is also small, but the installation is much simpler than in the previous case.

- Glass Ruberoid. It is produced using fiberglass or polyester as the base. This material is much more reliable than cardboard impregnated with bitumen. The presence of a solid base has significantly increased the life of the material, which can reach 15 years, and the resistance to accidental damage is much higher.

- Euroruberoid. This type of coating is also surfaced, however, it differs in that it can tolerate quite strong temperature extremes and severe frosts.The service life of the material approaches three decades, and the number of layers required to create a reliable roofing carpet is minimal.

- Membrane coating. This material is one of the latest developments. It has high durability and fast installation. An alternative is self-adhesive materials, which in warm weather can only be rolled out on the roof, after removing the protective film from the back. The downside of self-adhesive compounds is their cost.

Baseless roofing materials

One of the most attractive features of such coatings is the lack of a rigid structure, due to which they easily perceive deformations of the insulated base without reducing the degree of protection. Baseless materials include:

- isol;

- brizol;

- GMP;

- films.

Isol. This material is obtained from scrap rubber, which undergoes devulcanization in a bitumen medium. After this procedure, the introduction of a fibrous filler, for example, asbestos fibers, as well as a number of additives. Izol is flexible, resistant to decay, and easily tolerates deformations even at low temperatures. This material is waterproof, bio-resistant and ductile. Its properties are maintained in a wide temperature range (-30 .. + 100 C). The main use of the isol is waterproofing roofs.

The tensile strength of the material is up to 0.4 MPa, and the water saturation per day is less than 1% by weight. The weight of 1 m2 is only 1.5 kg. The inner side is protected from sticking in a roll with talc, chalk or other material similar in properties. There are only two types of isolate: the first of them is I-BD, which does not have polymer additives, and the second is I-PD, which contains special substances.

Brizol. This is a roll-type baseless material made from a mixture of petroleum bitumen having various viscosities with rubber. As a rule, shredded and recycled car tires are used here, as well as special plasticizers and fillers. In percentage terms, the composition is as follows: 60% is bitumen, 30% is rubber and 12% is asbestos. The proportion of plasticizer is small (2-5%).

The manufacturing technology of the material makes it chemically resistant. It can withstand 40% sulfuric acid, 20% hydrochloric acid and tolerates heating up to 60 C. These properties determined the purpose of brizol, which is used to isolate a flat inclined roof, laid with a layer of up to 35 mm. One of the features of the material is the ability to hold not only water, but also various gases.

Brizola canvases are delivered in the form of rolls, the inner surface of which is covered with finely divided mineral powder, which avoids sticking of the material during storage and delivery.

GMP. Under the abbreviation is a waterproofing material obtained from polyisobutylene. It is characterized by high quality and durability. There are 3 brands of GMF, designed to create multi-layer flat roofs, waterproofing and vapor barrier.

Film materials are also baseless. These include all known to all plastic films and polyamide materials. The main advantage of the films is their minimal thickness and almost complete water resistance, as well as low weight.

Polyethylene film is a good waterproofing material, but it is not without drawbacks. The main one is the effect of ultraviolet radiation, which destroys the structure of the film. The strength of the material allows it to withstand 4..8 MPa tensile strength. The heat resistance of the film is high and reaches 140 C, and the minimum temperature at which flexibility remains -60 C.

A polyethylene film is a frost-resistant waterproof material, which can also be used for building warm roofs.Polyamide film differs from polyethylene in higher tensile strength in the longitudinal direction, and in the transverse this parameter increases significantly. If the thickness of the polyethylene varies from 0.03 to 0.15 mm, then the polyamide film can be from 0.055 to 0.12 mm

Designation of roofing materials

Each type of coating has its own designation, consisting of numbers and letters. The first character is a letter indicating the type of material, for example, “P” - roofing material. In second place is the type of coating, which can be: “P” - lining, “K” - roofing, “E” - elastic. The appearance of the external topping is indicated by the third letter: “H” - scaly mica, “M” - fine-grained, “P” - dusty and “K” - coarse-grained. Completes the graphic designation of the material mark. This is a figure showing the density of the cardboard or the weight of its square meter. The higher it is, the material will be stronger.

Sometimes another letter appears in the designation - “O”. She says that the material has one-sided sprinkling.

Use the coatings in accordance with their intended use, because otherwise the service life will be much less.

Advantages of roll roofing

Roll soft roofing is a relatively inexpensive universal material, which has a low cost compared to other types of coatings. The advantages of a roll roof should be attributed primarily to the low weight of the material. This reduces the cost of transportation and installation.

The second feature of these coatings is that such material does not need to be regularly serviced, and the installation itself does not cause any special difficulties. Unlike other ways to protect the roof, it is not so long to lay a soft roof.

Another advantage of a properly arranged roofing cake using roll materials is a low noise level and good waterproofing. Moreover, modern coatings meet high fire safety requirements.

It is worth saying that the modern roofing material has a very high service life, which means that the roof will require repair no earlier than in 15-20 years.

What is a rolled roof made of?

Today, the raw materials for the main type of materials are:

- polyester;

- fiberglass;

- fiberglass.

Polyester is the most expensive and reliable foundation. This is a synthetic material made from polymer fiber. It will withstand tensile strength up to 60%, and the tensile force is almost 35 kgf / cm. The service life of polyester is also quite high.

Fiberglass fabric is made from interwoven fiberglass yarns. To create roofing materials, two types of fabric are used - smooth and frame. The first are obtained on the basis of torsion of threads covered with a sizing and forming a material having various types of weaving. The main advantage of smooth glass fabrics is their cheapness, and the disadvantage is that deformation is possible during transportation or storage. In particularly difficult cases, peeling of bitumen may even occur.

Frame fiberglass is made of flat glass rovings intertwined with glass thread. Such a base is attractive in that it does not break, and is practically not deformed. It is it that is used in the case when it is required to manufacture modern roofing material. Fiberglass is the strongest base, however, in the general case, the type of bitumen binder used also has an effect. If its quality is small, then the roof itself may not live up to expectations.

The main aspects regarding the materials used when creating a built-up roll roof were discussed above. Most of the attention was paid to the materials themselves, and the technology of their installation remained behind the scenes. In the event that you need it, on our website there is additional information regarding the installation of such coatings.

Alas, no comments yet. Be the first!