Monterrey metal tile stands out due to the technical characteristics of the material and its appearance. Among developers, this roof is very popular. It is in no way inferior to natural clay tiles in either quality or elegance.

Content

Monterrey Metal Roofing: Specifications and Benefits

This roofing material has a fairly high strength and flexibility, which greatly simplifies the installation process.

Since there are three options for metal roofing on the building materials market: Monterrey, Super Monterrey and Maxi, their technical characteristics have some differences.

Metal Monterrey:

- overall sheet width is 118 cm;

- useful sheet width is 110 cm;

- wave step - 35 cm;

- profile height - 3.9 cm.

Metal tile Supermonterrey:

- overall sheet width is 118 cm;

- useful sheet width is 110 cm;

- wave step - 35 cm;

- profile height - 4.6 cm.

Metal Maxi:

- overall sheet width is 118 cm;

- useful sheet width is 110 cm;

- wave step - 40 cm;

- profile height - 4.6 cm.

Zinc coating in the composition of the roofing sheet indicates its durability. The thicker the zinc coating, the higher the anticorrosion properties of metal tiles.

It has high frost resistance. The material is able to withstand temperatures from

-40 to + 110 ° C, while it does not crack and does not delaminate.

The coating does not fade under the influence of ultraviolet rays. This allows not only to preserve the color saturation, but also to save the soil layer that protects the metal sheet.

The protective layers do not lose their properties in the rain, wind and other weather influences.

Monterrey coating is able to maintain anti-corrosion properties up to 35 years.

The symmetrical profile wave gives the metal tile even greater similarity to natural materials.

The edge of the cut is made so that the junction of the upper and lower canvas of the tile is completely invisible.

Fastening is carried out using self-tapping screws, the consumption of which is 1 m? up to 8 pieces.

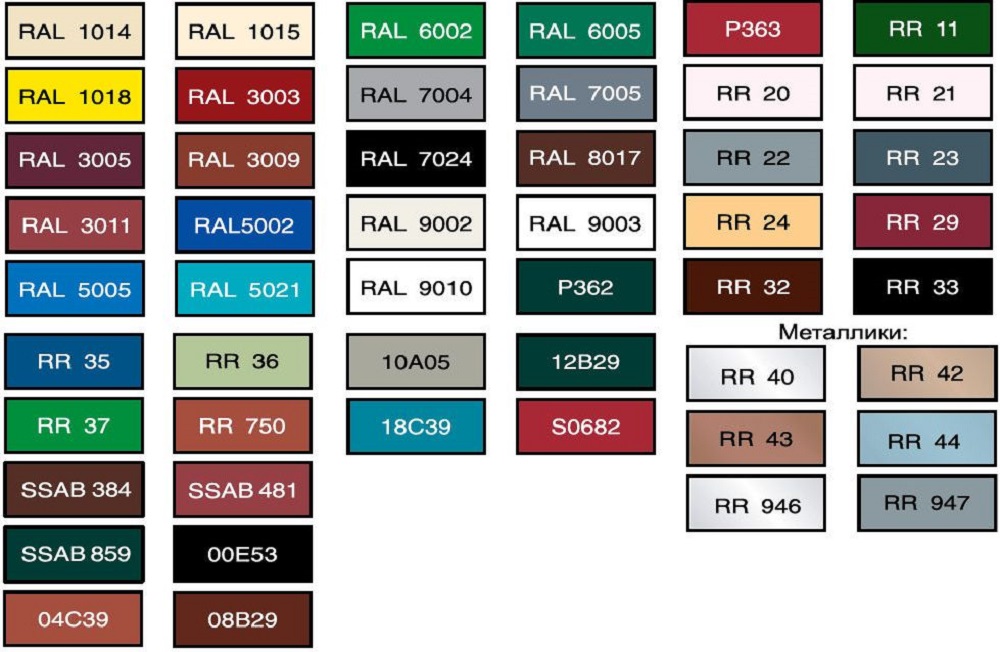

Color spectrum

Monterrey metal tile colors are diverse. Manufacturers spared no effort and developed specifically for this type of roof about 40 different shades.

This allows you to choose the roof for the most complex architectural structure and translate any plan into reality.

We draw your attention to the fact that it is advisable to purchase all additional roofing elements with tiles from one supplier. This is the only way to avoid problems when parts of the roof do not match in color.

Monterrey metal tile production

Monterrey roofing metal tiles are made by competent specialists on the highest order equipment equipped with automated production lines.

The metal tile is a steel sheet rolled to a certain thickness, on which special protective layers and a polymer coating are applied.

As the main raw material, galvanized steel is used, which is coated with the following layers:

- anticorrosive substance;

- primer;

- polymer.

Primed product is necessary so that the polymer has better adhesion to metal.

The polymer carries not only a decorative load, but also is the main owner of anticorrosion properties.

After the protective treatment process is completed, the metal sheets are given the desired profile shape.

Today, manual operations are practically not used in the manufacturing process, everything is automated. So, metal profiling is carried out on machines where the material passes a certain number of rolling stands. This profiling option makes it possible to ensure stability and accuracy of the rental.

Even on the raw material preparation line, multilevel product quality control is beginning to be applied.

Technical standards for the manufacture of roofs

In the process of production of the roof, the Monterrey GOST metal tile controls the indicators of the amount of metal used, coatings, as well as the quality of work.

It is necessary to take into account the requirements of the following state standards:

Galvanized sheet metal - GOST 14918-80;

Calculation of building metal structures - GOST 23118-78;

Flexible metal sheet profiles - GOST 24045-94.

Also, in the manufacture of Monterrey metal tiles, manufacturers control the quality of products according to the technical conditions of production (TU 1112-059-00110473-2002) and the international quality certificate (ISO 9000, 9001).

We draw your attention to the fact that the requirements of the international certificate of quality of ISO products are much higher than in accordance with GOST. This is especially true for tolerances on the thickness of the roofing sheet, steel and polymer coating.

Installation and operating tips

The metal tile should be stored in certain conditions: a dry room, it is necessary to exclude sudden changes in temperature, constantly increased humidity. The room should be well ventilated.

We recommend storing metal sheets, stacking them in piles and laying with wooden bars. This is necessary for better ventilation.

If it becomes necessary to store metal tiles on the street, it should be folded at an angle so that moisture does not accumulate and drain.

Installation work is preferably carried out with working gloves, since the edges of the material are sharp enough, which is very traumatic.

Material cutting can be done either with special scissors or with a power tool: a jigsaw, a circular saw, an electric hacksaw.

It is forbidden to cut the Monterrey metal tile with a grinder, since under the influence of friction, the temperature in the protective layers of the tile rises, and they collapse. This may cause rust or corrosion.

It is also not recommended to cut the sheets in the transverse direction with mechanical scissors, as there is a possibility of crushing the profile.

It is necessary to carry out all installation work very carefully, without damaging the surface of the tile. The resulting scratches and cuts should be treated with a primer and painted over with a suitable shade.

Sawdust and shavings, which inevitably form during the process of carving and installing metal tiles, must be carefully swept away from the coating. They can damage the upper protective layers. Also, if you do not remove the chips in time, then it can begin to rust. This, again, will lead to damage to the roof.

After installing the tile, you must immediately remove the protective film, as it either begins to melt and spoils the coating, or the metal under it, for no apparent reason, will begin to rust.

Metal Monterrey - sizes are diverse. Manufacturers offer lengths of up to 6 meters. It is most convenient to use sheets with a length of 3.5-4 meters. Less risk of damaging the roof during installation. Also, it is this length that assumes the ease of roofing.

It is advisable to inspect the roof several times a year for the integrity of the roof.If any damage is found, they must be repaired.

Using a lightning rod, you can protect the roof from lightning strikes and thereby protect its integrity.

Metal Monterrey MP is a reliable roofing material that can last for more than a dozen years. When fulfilling the above rules, there will be no problems with the installation and operation of blood.

Alas, no comments yet. Be the first!