Excellent consumer characteristics and low cost have made metal roofing the most popular in the construction market. Particularly popular are metal tiles and decking. These coatings are very similar. Therefore, it is not always easy for the consumer to decide which is better to choose for their construction.

Content

What is attractive metal roof for developers

Profiled metal sheets optimally combine unconditional reliability, durability and affordable price. Roofers note the ease of installation, especially on simple roofs. Among the significant characteristics of steel coatings, it should be noted:

- Ideal protection against wind and rainfall. The steel sheet is waterproof. Due to the perfect geometry, the joints of the panels are always tight.

- Strength. The metal withstands bending and tensile loads. Profiling gives it extra rigidity and stability.

- Moisture resistance. The metal tile and corrugated board are covered with several layers of corrosion protection.

- Fire safety. Steel does not burn and does not spread flame.

- Light weight. A square meter of metal roof weighs about 3 kg. This allows you to save on load-bearing structures, use the material in the repair and reconstruction of dilapidated buildings.

- Aesthetics. The profiled sheet is covered with a decorative layer, which makes it attractive and distinguishes from the surrounding environment.

- Quick installation. One panel immediately covers several square meters of the roof, which allows for roofing work in a short time.

- Unpretentiousness. Maintenance of metal roofs is minimal. They almost never litter and dirt, and some coatings have the ability to self-clean.

Many developers regretfully refuse metal roofs, because they rumble in the rain and hail. The reason for the increased noise of the metal roof is its poor-quality installation. Curved crate, uneven installation of insulating materials, loose coating of the coating to the base provoke vibration, which produces a crash. If the roof is covered by all the rules, its noise level is minimal.

The similarity of metal and profiled sheet

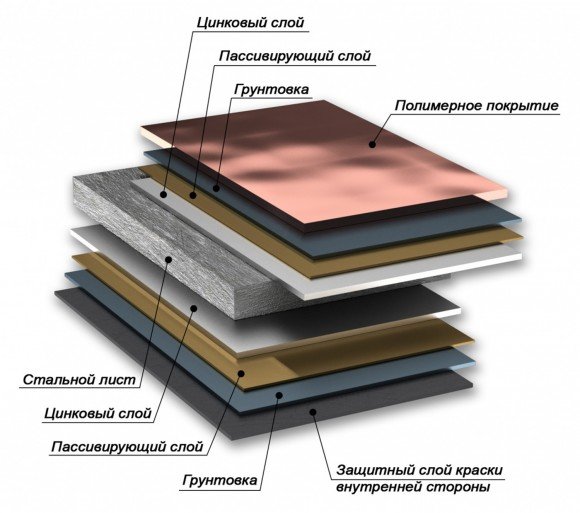

Metal and corrugated board are made of sheet steel. So that ferrous metal does not rust and lasts as long as possible, its rolls are covered with protective layers:

- Double-sided hot dip galvanizing. The sheet is immersed in molten zinc, which does not corrode in water.

- So that zinc does not react with chemical elements from the atmosphere, it is covered with a passivating layer.

- The next two-sided treatment is a high-adhesion primer, which provides adhesion of the decorative layer to the metal base.

- From the inside, the roll is coated with hydrophobic enamel or varnish. Condensate formed in the under-roof space rolls along it to the eaves.

- From the front side, one of 6 types of polymer coating is applied to the sheet. The cost and life of the roof depends on the polymer.

The polymers used are strong and flexible. They take the form of metal, do not crack in the sun, do not exfoliate in the cold. In production are used:

- PE - glossy polyester, 10 year warranty;

- PEMA - matt polyester, 10 year warranty;

- PU - glossy pural, 15 year warranty;

- PUMA - matt pural, 15 year warranty;

- PVDF - polyvinylidene fluoride, 15 year warranty;

- PVC - Plastisol, 5 year warranty.

The standard palette of different manufacturers includes 12-24 colors. On order, plants paint products in any color from the RAL palette.

Some manufacturers can see Printech coated metal tiles. This polyester film is slightly thicker than PEMA with a pattern that imitates the texture of natural materials: ceramics, wood, stone.

Metal and corrugated boards are made using similar technology.. The roll is unwound, rolled on profiling machines, cut into segments of a given length. Many manufacturers cover the front of the panels with a transparent film that protects the polymer coating from scratches during loading and transportation.

The process of manufacturing corrugated board in the photo

Both materials are equipped with special fasteners - uhthen galvanized self-tapping screws with a color polymer coating and a neoprene washer sealing the mounting hole.

A common drawback of metal and corrugated board is a large waste after installation. And the bigger it is, the more complicated the geometry of the roof. On a simple single- or gable roof, the scraps may not remain at all.

What is the difference between metal and corrugated board

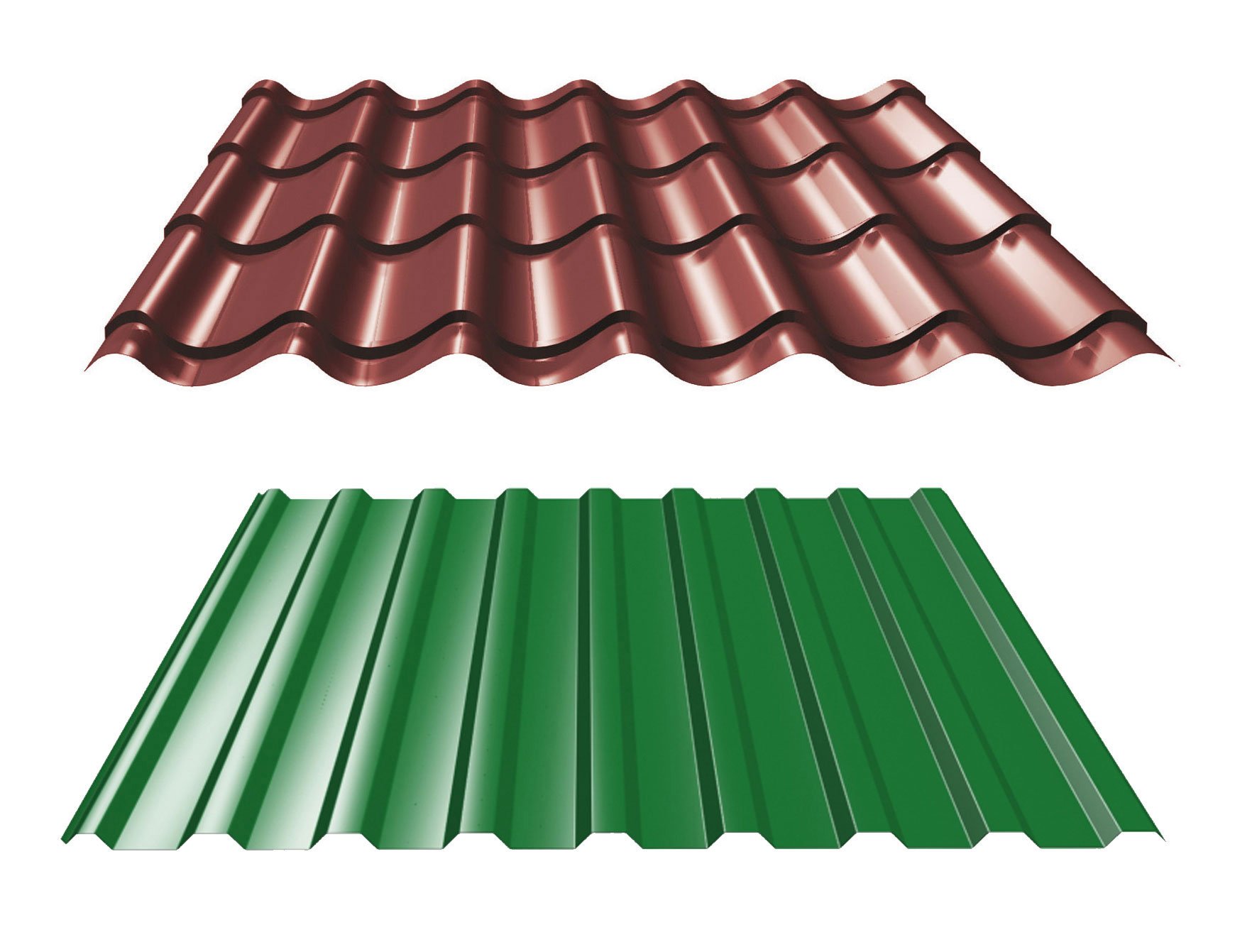

First of all, materials differ visually. The relief of most models of metal tiles is sinusoidal - wavy, imitating a ceramic roof.

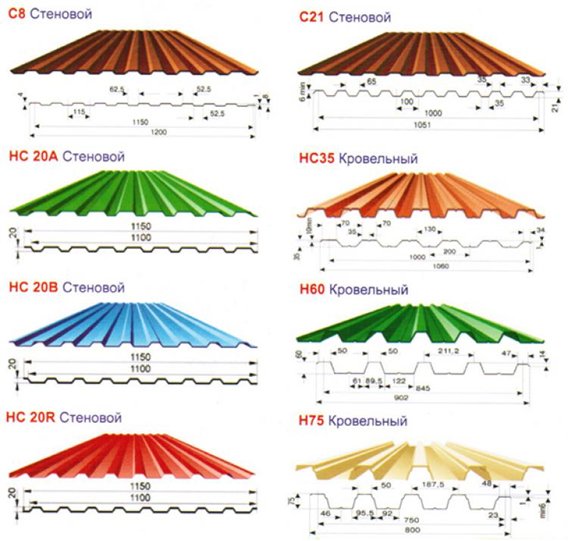

A profiled sheet is a corrugation, its waves have a rectangular or trapezoidal profile, sometimes with additional longitudinal bends and grooves.

After rolling on a roll forming machine, the metal tile is placed under the press, forming modules on it with a pitch of 300, 350 or 400 mm. Cross profiling makes the material look like ceramic ordinary tiles and enhances the rigidity of the panel.

Decking has only a longitudinal corrugation.

All metal tiles are available with color polymer coating. Budget options for corrugated board are sold with one zinc anti-corrosion layer. It does not look so beautiful, but its cost and service life are less.

There are many differences in the linear dimensions of metal roofing panels:

- Wave height. For metal tiles - 25–55 mm., For corrugated board - from 8 to 350 mm.

- The thickness of the metal. For standard metal tiles, a sheet of 0.45 and 0.5 mm is used., Premium - 0.6 mm., Budget - 0.4 mm. The profiled sheet rolls from a metal of 0.35-1.50 mm. For roofs, panels of 0.4-0.7 mm are used.

- Decking is produced in segments of standard lengths of 3, 6, 12 m. On order at the factory, panels from 1 to 13 m will be cut in increments of 1 m. The range of metal tile lengths is wider (0.4 - 8.0 m), and the cutting ratio depends on the length module.

- The width of the metal tile panels ranges from 1140 to 1190 mm. The width of the corrugated sheets is 645–1200 mm, and it depends on the size of the corrugation.

- Metal is used only for roofing, rarely - as a wall cladding. The scope of corrugated board is almost limitless. Thin low-profile grades are used for roofs, fences, cladding. High profile thick metal panels are used as floors and wall materials. Insulated sandwich panels for the assembly of containers, pavilions, stalls are made from the profiled sheet.

What material to use

Undoubtedly, the metal tile with its waves and three-dimensional relief looks much more elegant and richer.

The hard straight lines of the profiled sheet are weakly associated with the concept of a cozy roof.

If you are building a beautiful estate, a family nest, a profitable business, you need a metal tile. But it costs more, which is sometimes crucial when choosing coverage for budget construction.

On a roof with complex geometry and additional architectural elements (turrets, mezzanines, dormers, dormers, porches), the consumption of metal tile panels of different lengths will be more economical. On simple pitched and hip roofs, the waste material is the same.

The minimum angle of inclination of the roof for laying metal - 12 °. Under the corrugated board, the slope of the roof of the apartment building should also be at least 12 °. But its use is possible on technical buildings with a roof slope of 8 °.

Metal and roofing sheeting are the best choice for most roof construction and repair options. The cost of these materials and installation work is low. And if the homeowner has some roofing skills, the material will cost him quite cheaply. At the same time, the 50-year service of the metal roof coincides with the life of the building between overhauls. If all roofing work is done correctly, for half a century the roof will not be a hassle.

Commenting is closed