If you want your roof only to please with its performance and protect from various weather phenomena, then it is worth thinking about vapor barrier. Of course, some roofing materials allow its absence, but the use of additional means of protection is never superfluous.

Moisture acting on the roof can damage the rafter system, contributing to the formation of fungus, reduce the efficiency of thermal insulation or cause corrosion on the metal parts of the building structure. This can lead to the need to replace damaged materials, additional costs and so annoying repair. To prevent this from happening, it is recommended that you use a vapor barrier, but which one is yours to choose.

Content

Vapor barrier

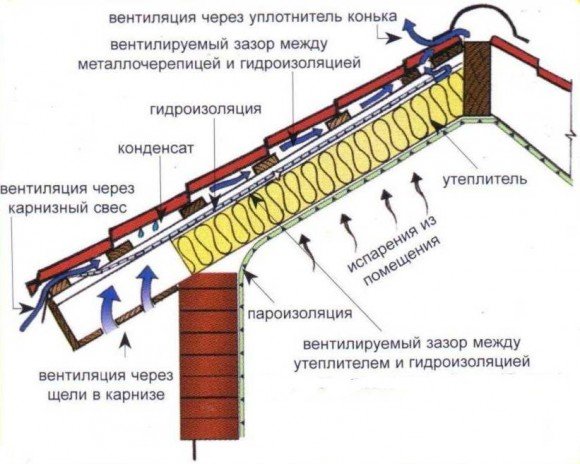

To begin with, we will determine why vapor barrier is needed. In a warm room, moist steam forms, the pressure of which is higher than atmospheric. Trying to go outside, steam flows up to the roof and can penetrate into the insulation. For example, mineral wool, when moistened by only 5%, can lose up to 50% of heat. The vapor barrier layer is placed under thermal insulation materials and thus protects it from moisture..

Materials for vapor barrier must have a combustibility of at least G2 and be absolutely leakproof.

Note: if the room humidity exceeds 60%, then it is impossible to ignore the use of a vapor barrier.

Traditional materials

The traditional vapor barrier material is glassine. But technology is moving forward, and now it no longer meets modern requirements. Unfortunately, among the main qualities of the glassine, only shortcomings can be listed: it does not have sufficient strength and reliability. Weak insulating properties and low environmental friendliness will not lead to a choice in his favor.

The next material, which has been used for a long time, but still holds its position, is roofing material. For its fastening, it is necessary to prepare a hard flooring, under which it is desirable to leave a ventilation gap. Due to the additional consumption of material, the cost of the roof may increase.

About 1-5% of the cost of the entire roof is usually spent on laying a vapor barrier.

In addition, roofing material often loses its technical properties due to the constant change in temperature and the influence of natural factors. However, in some repair and construction works, such as the erection of farm buildings and the installation of a flat roof, the use of material is still acceptable.

Manufacturers of vapor barrier films began to produce improved analogues of roofing material, abandoning the cardboard base used in it in favor of a new material - polyester. Thus, not only the ability to withstand the effects of external factors is increased, but also the elasticity.

Paint vapor barrier

It is rarely used in private construction and is more suitable for roofing materials made of steel profiled sheets, where insulation is not used.. The complexity of using such a material in surface preparation. It must be cleaned and dried, the bumps should be wiped. Mastic is applied in an even layer, preventing the formation of empty areas. Bitumen, tar or tar mastic must be heated to a certain temperature before application.You can use cold mastics, for example, asphalt or bitumen-cocker, as well as polyvinyl chloride varnishes.

Nakleechny vapor barrier

It is the most popular because of the simplicity of installation and the small number of seams that retain their tightness when laying overlap. This vapor barrier is available in the form of roll films.

As a vapor barrier layer for a concrete roof, you can choose bitumen membranes that have a large specific gravity, but are very simple to install: they simply deposit on a concrete base. Due to its flexibility, bitumen membranes have the ability to independently recover in places of fracture or deflection.

Lightweight non-perforated vapor barrier films are now very popular. They are used for both flat and pitched roofs. Films can be single or double sided; there are also differences in density, combustibility and resistance to ultraviolet radiation. The advantages of these films include safety for health, as well as resistance to mold and rot.

An important aspect when laying a vapor barrier film is its one-sidedness.. The property not to let off steam works only in one direction. If reflective materials are used, the metallized side should face the room. There are double-sided films on sale, which can be stacked on either side on top of the insulation.

The vapor barrier layer must be continuous; at the joints, foil tape is used as a fastener. On the rafters, the film is fixed with wooden slats. In a house with wooden building structures, galvanized nails or staples are used for fastening. If it is necessary to carry out fastening to other materials, for example, metal or brick, then use double-sided tape or tape.

Before installation, it is necessary to seal the attachment points to chimneys and other relief elements of the roof. Stoves and chimneys, while extracting heat, can cause damage to the vapor barrier layer adjacent to them, so additional insulation does not hurt at all.

Between the film and the insulation it is better to leave a space that will help maintain heat and ventilation. This can not be done if breathing membranes are used.

Film materials for vapor barrier:

-

A plastic film is placed between the ceiling and the insulation. It can be reinforced, unreinforced or have an additional layer of foil.

-

Polypropylene film has high strength and resistance to UV. It can be used to protect the building from rainfall during the installation of the roof.

-

The diffuse membrane has a non-woven structure. Protecting from the penetration of moisture, it does not prevent wet steam from leaving the room. It is laid on a heat-insulating material and provides constant ventilation.

Films and membranes of the future

Anti-condensation films will help to avoid the accumulation of moisture in the insulation. They include a special adsorbent layer, which is applied to the lower part of the fleecy fabric and forms the basis of the material. With its help, the film is able to not let moisture through and contribute to its weathering. The film must be in contact with air, and not with a hard surface, so that this does not affect the loss of technical qualities.

When choosing a vapor barrier material, there may be a need to acquire the best quality material - superdiffusive breathing membranes. This material is ultra-thin, because the layer thickness is from 0.2 mm. Its advantages are light weight, high strength and long service life of 30-50 years.

Superdiffusion vapor barrier consists of two or three layers. The two-layer material consists of polypropylene fabric and one layer of polyethylene laminate. The basis of the three-layer vapor barrier is mesh polypropylene, which is laminated on both sides with a plastic film.

For specific operating conditions, modified membrane versions with an additional effect are suitable. If you need to make a vapor barrier device for a flat roof with a metal coating, then you need to think about the fact that the surface of such a structure can be subject to significant overheating. In this situation, films that do not lose their technical features due to the action of high temperatures will help. It will be useful to owners of rebate roofs, as well as roofs with metal or metal roofing.

Sometimes the task is to maintain the maximum amount of heat in the room, for example, when designing a bath or sauna, when powerful convection currents are formed. An ideal choice would be the use of vapor barrier, which reflects thermal rays and is characterized by increased intensity. There are now metallic-type coatings that meet these requirements. They will help to keep warm and will prevent the formation of condensation on the walls.

Vapor barrier materials and their installation

Video tips for choosing a material for creating a vapor barrier

//www.youtube.com/watch?v=gQfEoQfaO0Y

Alas, no comments yet. Be the first!