Today, the number of roof options is simply amazing. Dozens of types of coatings are available for individual construction, and there is no need to talk about the technology of the rafter system. Many of these materials are not easy to lay, and some require the use of special installation methods and taking into account a number of other points. Most of these rules contain SNiP: roofs, insulation or rafter systems should be built in accordance with them.

Today, there are several SNiP affecting the construction of roofs. The most common of them is the code of norms and rules II-26-76 *, the latest edition of which was in 2010. This is a document containing installation technologies for all the materials used today, so it is from its consideration that we will begin this article.

All materials used to create one or another element of the roof of the building must comply with the applicable technical specifications or other standards.

SNiP, under the number II-26-76 * among others, includes items relating to:

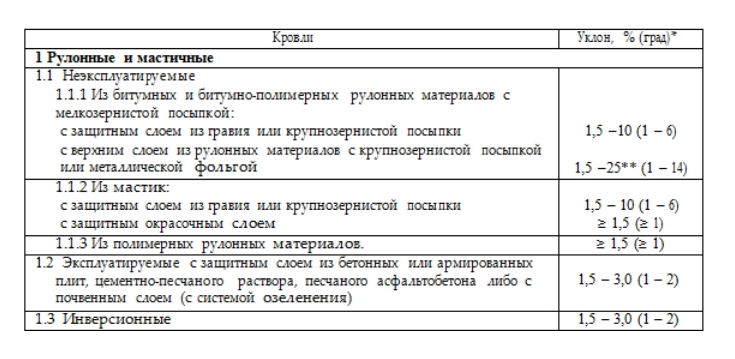

- rolled roofs;

- small or wavy sheet materials;

- flexible tile roofs;

- technology of installation of metal;

- asbestos-cement or bitumen sheets.

- sheet metal roofing.

Content

Rolled Roofs

According to SNiP, they can be made with either a traditional or an inverse arrangement of a waterproofing carpet. In the first case, there is a classic way of laying the waterproofing layer, and in the second, the thermal insulation is higher. When using the inverse version, it is supposed to use reinforced concrete slabs, cement screed or a layer of light concrete, forming a small slope. It should be noted that in the case of creating an inverse roof device, only waterproofing materials on a non-rotting basis should be used. Expanded polystyrene, which is characterized by minimal water absorption, is selected for the role of heat-insulating material, which means that it virtually eliminates the possibility of defrosting during operation.

The following types of flat surfaces can claim the role of a base for a roofing carpet:

- Reinforced concrete slabs. The seams between them should be filled with M100 mortar or concrete with a class above B7.5.

- Thermal insulation boards. In this case, the mineral fiber base should withstand well the effects of gasoline and other organic solvents such as gasoline, nefras, ethyl acetate, etc. In the case of using hot mastic, it is recommended to make sure that the temperature of the melt does not damage the insulating material.

- Monolithic reinforced concrete. It is allowed to use only lightweight concrete and other compositions obtained using lightweight aggregates such as vermiculite, perlite, etc.

- Monolithic leveling screeds or cement-based dry screeds. Prefabricated screeds can also be used. They are made of asbestos-cement sheets up to 10 mm thick.

When a cement-sand screed is used, a layer of bitumen roll coating is required between it and the heat-insulating material.

When arranging leveling screeds, it is recommended to perform heat-shrink seams. Their width can reach 10 mm and avoids the destruction of the material due to temperature changes.Typically, such seams divide the coating into squares with a side of 6 m, and if sandy asphalt concrete is used, then the side should be less than 4 m.

Small-piece sheet and wavy materials

According to SNiP, roofing work with such materials is carried out in the attic roofs, as well as in those buildings where the attic is not heated. In a similar situation can be used:

- Cement and sand tiles. As an alternative to this material, you can choose ceramic tiles. They are used at tilt angles of 10 to 90 and 22 to 60 degrees, respectively. In some cases, additional fastening of the tiles with screws is required, and for some tilt angles it is necessary to install a waterproofing carpet under the roof.

- Flexible tile. The basis for this material is a continuous flooring made of boards, plywood or OSP-3. The moisture content of the tree is selected less than 20%, and for plywood this parameter can be within 12%. The pitch of the rafters during installation is selected from 600 to 1500 mm, and the thickness of the flooring depends on the pitch.

- Metal tile. Such sheets having a decorative and protective coating can be used on slopes above 20%. Their use in the range from 10 to 20% is also allowed, but then it is necessary to seal the transverse and longitudinal joints of the elements.

- Asbestos-cement or bitumen wavy sheets. Such materials are suitable for simple forms, for example, a gable or gable roof. The SNiP discusses the features of the installation of these coatings, and in the annex to it (Appendix 11) there is a detailed description of the details of the roofs.

- Asbestos-cement and slate tiles. They can be mounted on a continuous crate of boards, and a waterproofing layer is laid on top of the rafter structures.

Profiled metal sheet

According to SNiP, roofs from corrugated board are created using profiles having aluminum or zinc coating. Metal sheet can be used when you need to create cold roofs or roofs, assembled in layers. Most design solutions are recommended to be selected from the same group that is used for the installation of metal tiles.

The roof from a profiled sheet is excellent for buildings in which the slope is up to 12 m, and the angle of inclination is above 20%. If the slope of the ramps is 10..20 degrees, it is necessary to perform mandatory sealing of the joints located between the sheets.

As a base for the roof, a wooden beam should be used when an insulated roof is created, or metal structures for a cold roof. In the first case, it is necessary to avoid the occurrence of "cold bridges" and use thermal profiles or gaskets made of Bakelized plywood (at least 10 mm thick). Additional protection of the insulating material is carried out by applying pentaphthalic or vinyl enamels. The fastening of the profiled sheets themselves should be performed using special self-tapping screws having a sealing washer. Seals made of 1 mm neoprene rubber have proven their best.

Sheet Metal Roofs

For such cases, SNiP recommends the use of roofing steel or copper tapes. Fasteners in the first case should be galvanized (for steel coating), and in the second - copper.

Appendix 14 SNiP II-26-76 * contains the main structural solutions for roof coatings made of materials such as sheet steel, copper or zinc-titanium.

When using galvanized steel, it is recommended to use a wooden crate: a beam of 50x50 mm or boards 50x120, 50x140 mm. The construction of the overhang is performed without gaps, and the width of the resulting flooring should be at least 70 cm. Then, parallel to the overhang, the bars of the battens are placed, which are at a distance of up to 20 cm. The battens should be alternated with the board, which is used to place the folds.

SNiP "Wooden structures"

Building materials from wood today are in great demand, since many different impregnations have appeared that protect them from fire and biological damage. In the case of the creation of such structures, they are guided by the provisions of the code of rules 64.13330.2011, which in fact is a revised SNiP II-25-80.

The action of the joint venture extends to methods that allow you to calculate and design structures of wood (solid or glued), which are used in any construction industry. The exception is hydraulic structures, bridges, foundations and piles, technologies, the implementation of which is not included in this set of rules.

When creating wood structures, due attention should be paid to their protection against biological damage. According to SNiP, a soft roof is created using wood rafters, however, the issue of fireproof processing and ensuring the safety of the material is not considered in it.

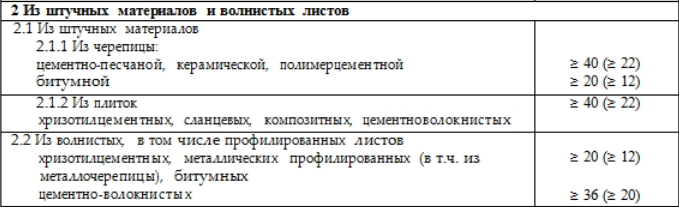

The quality of wood for creating roof structures must comply with the requirements listed in Appendix B to the joint venture. The strength characteristics of the tree are indicated in Appendix B.

When using glued structures, there is a restriction in the prohibition of using them if the air humidity is less than 45% and the temperature is lower than 35 ° C.

A tree should not have any defects to create loose leaves, nails and other elements, and its moisture content is recommended to choose less than 12%. If wood that is not resistant to decay, such as birch or beech, is used, then they must be treated with antiseptics.

For gluing individual elements, only those adhesives should be used that are indicated for each situation in the set of rules, because otherwise the strength of the joint and its reliability may be insufficient. Tables of characteristic values and corresponding coefficients for materials are also given here:

- working under constant load;

- experiencing strong short-term loads (wind, etc.);

- for various climatic zones;

- for elements that have been impregnated with flame retardants;

The set of rules also contains methods for calculating various structures made of wood. Here are formulas for calculating the parameters of centrally-stretched elements, centrally-compressed, longitudinal bending coefficient and a number of other important indicators.

The joint venture includes algorithms that allow you to calculate the most different types of compounds: glue, nail, on the notches, etc. It also provides methods for attaching wooden elements using glued rods or plate nails.

This set of rules is an indispensable tool when you need to design or calculate a crate, girder or flooring. It provides technologies for creating composite beams, as well as beams from solid and glued wood, trusses and composite materials.

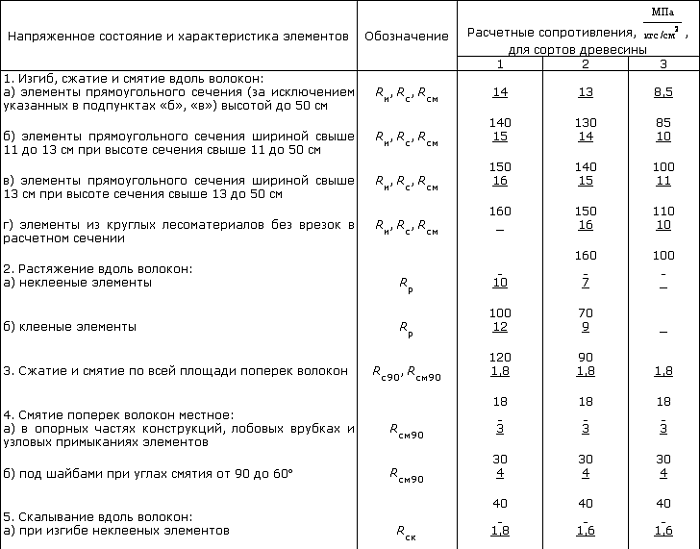

Load calculation

A construction of any type experiences various influences, and even its roof is even more so. This element is constantly exposed to wind, water, and in winter it can be damaged by snow or the formed layer of thick ice. You can get around this problem only by calculating all the possible loads and adding them to the project. For this, the specialist is guided by the provisions of SNiP “Loads and Impacts” under the number 2.01.07-85 *.

This standard provides an algorithm that allows you to predetermine the value of the snow load on the horizontal projection of the roof, and therefore, take the necessary measures before the roof begins to be embodied in the material. For calculations, the calculated values of the coefficients used for various regions of the Russian Federation are used. Appendix 5 to SNiP contains a map containing the corresponding marks.

When a soft roof device is manufactured, SNiP 2.01.07-85 * recommends taking into account the wind load, which depends on the region and roof structure. In general, this parameter can be represented as a combination:

- The normal pressure that is applied to the outside of the roof, and the frictional force directed along the tangent.

- The projections of external forces due to the general resistance of the roof structure.

The wind load consists of an averaged component and the magnitude of the ripple. The calculated value is composed of these terms.

Thermal protection

The quality of a building is determined not only by its reliability, but also by its ease of use. Few people want to live in a house where walls let heat out, acting as a kind of heaters. The energy costs for heating such a room will be simply astronomical, and the effect of a typical heating system will be minimal.

Roof insulation is carried out in accordance with SNiP "Thermal protection of buildings" 23-02-2003. Soon, this document is expected to be replaced by a set of rules, but at the moment it is still valid. SNiP does not apply to the following buildings:

- places of worship;

- greenhouses, hotbeds and refrigerated buildings;

- temporary structures in operation no more than two heating seasons;

- transformer substations, as well as boiler rooms and other engineering structures;

- buildings that are heated seasonally for less than three months a year or less than 3 days a week.

An exception is also made by various objects that relate to cultural heritage and historical objects that are under restoration.

For carrying out heat engineering calculations, special data will be required, the tabular values of which are given in the appendix to SNiP 23-02-2003. This document also has an example of designing a residential building.

It should be noted that SNiP not only considers the issues of reducing heat loss, but also methods to increase the service life and efficiency of using heat-insulating material. This moment is important for the roof, because if it is not taken into account, the air saturated with water vapor will reduce the quality of insulation day after day, saturating the insulating layer with water.

The most optimal way to protect against waterlogging is to use vapor barrier materials. The code of practice contains an example of calculating the resistance to vapor permeation, as well as a table of incremental moisture increments in the material, necessary for the calculations.

Above, we examined most of the documents that are fundamental in the construction of a roof. According to SNiP, roofing from corrugated board is a simple and reliable solution that can be implemented based on the information and articles provided in the codes of practice on our website. It should be noted that this contains only theoretical knowledge, which may not replace the presence of practical experience, therefore, everyone must decide for himself how to build a roof.

Alas, no comments yet. Be the first!