The roof is a very important stage in the construction and repair of any building. A correctly designed and assembled rafter system must not only withstand all significant roof loads, but also take into account local climatic conditions. There are two main types of load-bearing roof structures: layered and hanging rafters. In the construction of buildings that do not have bearing capital walls, hanging rafters are usually used, otherwise they are layered.

Content

Stage design rafter system

To solve the difficult task of designing a roof truss system, not only theoretical knowledge on this issue is required, but also practical experience. Only a professional can correctly determine the potential load on the roof, calculate the shape of the truss, the location of the rafters and their optimal cross-section. Therefore, in order to avoid mistakes and troubles, do not experiment, but rather entrust this important matter to specialists.

When designing roof structures, the following should be considered:

- angle of inclination and type of roof;

- material that will cover the roof;

- climatic conditions of the area (wind strength, rainfall and others).

Do not underestimate any seemingly unimportant load, as this can lead to an error in the calculations and, as a consequence, to deformation of the rafter system itself, as well as to the destruction of the roofing or even the entire roof. Only the right calculation and competent installation will give the necessary stability and strength of the entire roof structure during the construction of the pitched roof of the building.

Hanging rafters, application area

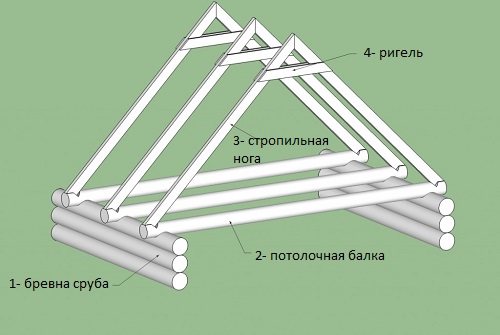

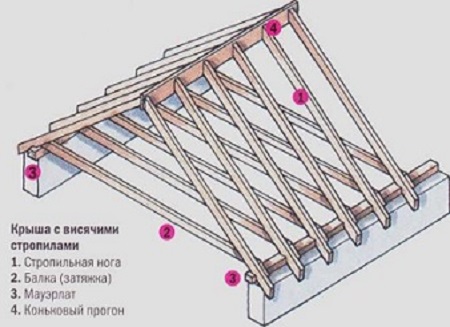

Hanging rafters are usually used in the construction of the roof of buildings in which there are no internal load-bearing walls. Such structures do not have supports inside, but rely only on two external main supports, which, for example, can be the outer wall of the building.

At the same time, the rafters do not create horizontal loads, but only work on compression and bending. To reduce the bursting forces exerted on the walls of the house by hanging rafters, a tightening should be used that connects all the elements into a single structure.

The puff can be made of metal or a solid wooden beam, and arranged based on the design features of the roof. For example, when erecting a mansard roof, you should use the suspension of the hanging rafters located at the base so that it also functions as a floor beam.

The greater the load the puff experiences, the higher it should be located in the rafter system.

It is very important to use powerful rafter structures and control the reliability of the fasteners, if you use the top location of the tightening. If hanging rafters are used, the span width should be 6 - 10 meters, and they are usually made of wood (logs, beams, boards), and when connecting the elements together, bolts, cuttings, pins, steel profiles and nails are used.

A little about rafters

The roof rafters are usually made of wood and are used in houses with a solid internal wall.The main difference between this design and the hanging rafters is the presence of internal elements (wall, column), on which the roof truss system is based.

In a design with layered rafters, loads are transmitted only to bending. Such roofs are obtained, firstly, lighter, and, secondly, cost-effective, since less timber is spent on its construction.

If you have not one, but several spans over which a common roof is being erected, then you can alternate the roof and hanging rafters: where there are internal supports, use the system of roof rafters, and where there are none - hanging.

The initial stage of installation of hanging rafters

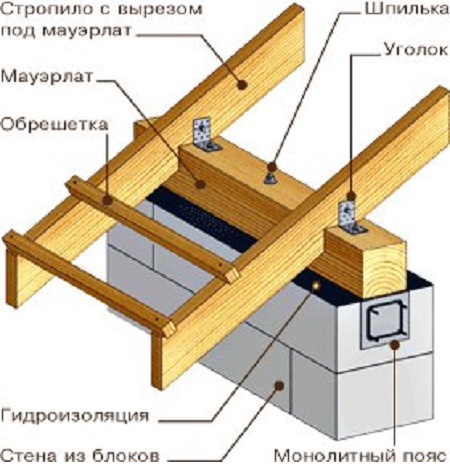

At the initial stages of the installation of the rafter system, after strengthening the Mauerlat, scaffolds (including mobile ones) should be constructed, which are a necessary element for lifting not only workers, but also materials that should always be at hand on the roof or other necessary height.

The cross section of the beam for the rafters should be at least 200 mm? 50 mm. If the cross-section of the beam is smaller, then the rafters may sag during further operation. All wooden structural elements should also be treated with a solution of a special antiseptic, which will protect the wood from destruction.

When arranging scaffolding, be sure to solve all the problems of convenience and safety of work, and only after that begin installation of the rafter hanging systems.

The procedure for installing rafters from a wooden beam

When installing rafters from a wooden beam, you should adhere to the following order:

- with the help of the previously constructed scaffolding, we raise two beams up and connect them;

- on the rafter's foot we cut a notch, which will be required to create a stable support on a strong Mauerlat.

- you need to cut a similar recess on the second leg of the rafters;

- we mark both the right and left rafter legs;

- we install wooden rafters, connecting them;

- we make recesses in the upper part of the marked rafter legs in such a way that the joining of the beam was with an emphasis, and not with an overlap (the overlap joint is considered unreliable even with good nailing);

To correctly make the upper recess, you need to connect the bars to each other and outline a cut line with a marker. Then make a notch and reconnect the rafters.

- when the first two rafter legs are already ready, they should be well measured and patterns should be performed separately for the left and right “legs” (using the templates you can prepare all subsequent boards on the ground, that is, without raising them to the level of the roof);

- Having installed the rafters in their place, we attach them with nails to the Mauerlat;

- like all subsequent ones, we prepare the second pair of legs directly on the ground with the help of previously made patterns;

- after that we install the finished second pair on the opposite edge of the roof;

- Next, between the installed pairs of legs, stretch the rope, which will become the working level during the installation and fastening of the remaining pairs.

We install all rafters at a distance determined by the created project. For example, if the angle of the roof is 30 degrees, then the distance will be somewhere around 70 cm.

Installation work on the installation of bars hanging rafters

It is recommended for convenience to pre-mark the required distance and make notes on the Mauerlat, after which, according to the markings, install the rafters.

The height of the rafters is regulated by the twine, which was pulled earlier between the first two pairs. Wooden spacers can be used if the height is not enough.

According to the markings previously applied to the Mauerlat, we adjust the distance between the pairs of neighboring rafters at the bottom, and at the top we select the distance using the installed temporary board, the marking on which is applied similarly to the bottom.

The assembled structure will not be stable if the distance between the wall supports is large enough.Therefore, in order to tie the rafters, you need to use a special tightening (located horizontally beam).

In the case when the width of the house is quite large, then you have to tighten so that several boards fit together. The boards are usually fastened with nails, and they are screwed to the legs of the installed rafters with studs or bolts.

Do not forget to monitor and constantly measure the distance between the puffs, which should be consistent with that which is installed between the legs of the rafters. For these purposes, we suggest using small planks with markings applied similarly to the markings on the Mauerlat.

We recommend additionally connecting the ridge of the pair of rafters and the tightening to impart the required rigidity to the structure, otherwise the tightening under its weight can be significantly deformed. Such actions must be performed with each of the rafter pairs!

If at the beginning of the construction of the roof truss structure the legs were attached to the Mauerlat using nails, then at the final stage of assembly it is necessary to strengthen more carefully and reliably with the help of fastening strips of thin steel (splints).

This is done as follows: the rafter leg is wrapped with a tire, and then nails are driven in or screwed into the Mauerlat from the inside from two sides through a strip of metal to a depth of 30 cm. All these actions will help prevent the risk of destruction of the erected roof in the event of a strong gusty wind.

DIY roofing: the intricacies of the eaves overhang device

You should also know that no roof can have an eaves overhang. It is necessary so that water (precipitation) that has fallen on the roof does not flow inside the structure created, but is completely safely removed.

When creating a rafter system, it sometimes turns out that there is not enough length of the beam for the device of such an overhang (the beam is designed only for the legs of the rafters). Then they resort to building up the raised rafters.

It is recommended to make the length of the overhang of the roof not less than 40 centimeters, and sometimes it is increased to 60. Therefore, it is precisely by this amount that the rafters need to be lengthened using a board of the required length for this purpose.

And such a solution is considered more profitable and convenient than the use of a long beam: it is easier to work with smaller parts, the beam is more expensive, and if there is a need to repair the overhang, then the board is easier to replace without significant interference with the main structure.

So, we learned that the hanging rafter systems are the supporting structure of the roof and are widely used in the construction of buildings without internal supports (main walls, columns). Observing the installation rules, you can get a very durable and reliable roof!

Alas, no comments yet. Be the first!