A house made of wood suggests that the roof structures will be made of this material. Typically, such roofs are created with a slope, but their flat versions can also be used. It is also worth noting that flat roofs are inappropriate to use where a large amount of snow falls, and they also have a second drawback. This type of structure makes it impossible to build an attic, which means that the number of residential premises in a country wooden house will be less. When it is planned to build a roof for a wooden house, choose one of the following options:

- Single-handed. It is suitable for small buildings and is most often used for any household structures. Such a roof can be used for a bathhouse or garage. Its main advantage is that it requires a minimum amount of building materials.

- Gable. The attractiveness of this option is that it allows you to solve several problems that appear when you need to make a roof for a wooden house. The first feature of such structures is that they can be created taking into account the climatic features of the area of construction. For example, where a large amount of snow falls, it is best to use a significant slope angle. If the winter is warm, then the slopes are very steep are not required. The second positive point is the possibility of creating a warm attic. In fact, this room turns into another large room, expanding the living space.

- Four-slope. Such roofs are also called hip, because they have lateral slopes - hips. The first thing to say about roofs of this type is their complexity. A non-specialist can erect a wooden gable structure, however, it will not be easy to assemble a gable roof even with calculation and drawing. Of course, the difficulties in the installation process are offset by excellent appearance and sufficiently high reliability.

I must say that there are other options for the construction of roofs, for example, four-slope, which is a special case of a hip roof device. It has slopes of equal area and is suitable only for buildings with a square base.

Content

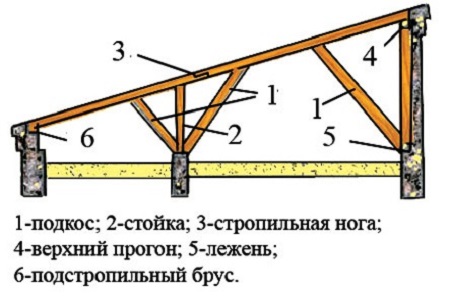

Shed roof truss system

For such structures, a slope should be maintained within 10-20 degrees if a profiled metal sheet is used, and 25 degrees for a metal tile. In the general case, for each material, the corresponding slope should be chosen, but it must also be remembered that the snow load depends on this parameter. The greater the slope, the faster the snow will come off the roof under its own weight.

We must not forget about the device of the gaps between the rafters and the roofing material, since it is they that make it possible to solve the problem caused by high humidity. These are ducts for natural ventilation, which creates suitable conditions for the removal of moisture condensed in the subroofing space.

The shed roof has the simplest rafter structure of all possible. In this case, the rafters rest on the Mauerlat from two sides. The timber is laid along the lower and upper walls, after which the wooden elements are firmly fixed. It must be said that the maximum length of the rafter leg is 4.5 m, if it was made of solid wood.When it is planned to erect roofs where a longer rafter is required, it is better to choose a gable variety or some other option.

Gable roof system

In addition to the division into types of roofs, there is also a breakdown by subspecies. So gable roofs can be:

- symmetrical;

- broken;

- asymmetrical.

Symmetric structures are created in different ways, the choice of one of which depends on the distance between the walls. If the width of the house is only 6 m, then it is enough to install the bolt and puff. The crossbar is usually performed closer to the ridge node, and the attic floor is laid on puffs. For a house whose walls are 10 meters apart, you will need to use struts and a stand called a grandmother. She props up the ridge knot, and the struts hold the rafters. These three elements (headstock and 2 struts) in the lower part are combined and rely on tightening strictly under the ridge node. Sometimes they do with the use of one rack, propping up the place of connection of the rafter legs with each other, but this approach is permissible only when between the walls no more than 7.5 m.

There is another kind of hanging rafters, which involves the use of sleepers. The latter are special wooden elements that are used as an alternative to puffs. In this case, runs are supported on the floor beam with which the sleepers are connected. Their length does not exceed 1/3 of the distance between the walls, so the lower part of the rafters does not require any additional clamp. Retention is due to the strut connecting the rafter leg and the sleepers.

All of the designs described above can only be used in conjunction with a Mauerlat. Of course, in the house of logs it is not necessary to mount an additional beam, since the last row of logs takes on its role.

Another option for attic building is the use of a broken gable roof. It allows you to get a lot of space for the attic, but its design will require more materials, time and skills. The upper part of the roof is formed through the use of hanging rafters. They are connected in the ridge and supported by a grandmother, which relies on a puff. The lower parts of the rafters are connected with a puff, and it rests on the racks. The height of the racks determines the height of the ceiling in the attic. The racks themselves are installed on the floor beam, which is the basis for creating the floor in the room.

Side slopes are formed by layered rafters. The rafters are connected with the upper part to the angle of the structure formed by the tie and the uprights, and the lower with the floor beam. To increase the reliability of the roof, struts can be used that reinforce the lower pair of slopes.

Fights are often used as an alternative to struts. So they call horizontally placed wooden bars connecting the construction site and the rafter leg. Another option is additional racks that rest on the floor beam in those places where there are load-bearing walls under it. This approach provides the ability to unload the floor.

Rafters for a four-pitched roof

A hip roof is more complicated than usual, since several types of rafters are used here, and their connection is not always simple. Moreover, in some cases, the length of the finished elements is not enough, therefore, prefabricated structures are created that require additional reinforcement. The roof is supported by a Mauerlat, into which a beam and rafters cut into. The rafter system consists of:

- Diagonal rafters. They are also called nasal. They are directed to the corners of the building and act as a support for the upper parts of the hip rafters.

- Narozhnikov. These are shortened rafters that are used on parts of the main slopes for the device of the hips.

- Racks and struts.Here they perform the same function as in the remaining cases: they ensure the reliability of the roof and protect against accidental damage while increasing the load on the structure.

- Lodges, runs and crossbars. These elements are also necessary. Without them, the installation of the roof of a wooden house would be very difficult.

A run is a support beam that will be parallel to the Mauerlat. This element is an additional support for rafters, so it is positioned so that it allows you to remove part of the load. In the case of a hip roof, the girder can be installed during the creation of the ridge unit, however, tent structures can already be erected without it.

The optimal distance between the runs and the Mauerlat is only 4.5 m. Compliance with this rule allows you to do without additional racks. Sprengels or structures called truss trusses can also be used. In the latter case, we are talking about a spreel, which is connected to the base not only with a steel pin and a pair of straight staples, but also with two wooden elements.

When installing a four-pitched roof, a number of simple rules should be observed:

- To create slant rafters, it is necessary to use a double structure of the same material that goes to create all the other elements.

- It is best to merge the upper parts of the rafters where the greatest load is applied, and also to strengthen them with the help of struts and vertical racks. The racks themselves are positioned so that they are perpendicular to the direction of the rafter leg.

- Rafter rafters need to be made with a small margin of length. In the event that it turned out to be too large, the structure is easier to trim. It is not recommended to build up such elements, since each joint is a potential weak point.

- The most critical nodes need to be strengthened by perforated metal fasteners or fixed with a wire rod.

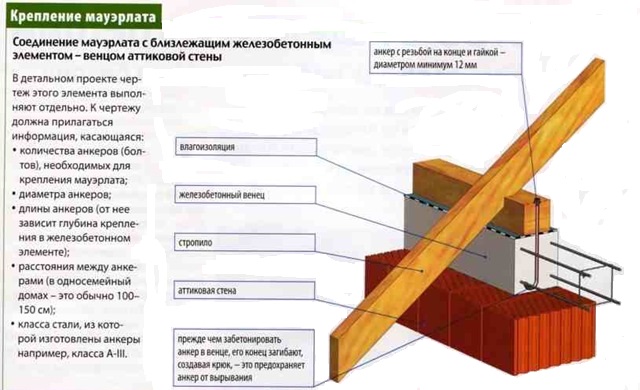

One of the important elements of the rafter system is the Mauerlat, which we will discuss below.

Mauerlat and its installation

The objective of this element is to distribute the total weight of the roof along the wall of the building. To achieve a positive result, it will be necessary to securely fasten the beam. It is best to use a cross section of 15x15 cm, however, you can choose 15x10 or even 50x150 boards.

Rafter legs can be fixed in several ways:

- using pins;

- staples;

- corners;

- wire rod.

Each of these options is used together with cuts in the Mauerlat, due to which a strong connection of the two elements is achieved.

Often a combined installation method is also used, involving the use of two types of fasteners, one of which is wire rod. Such a roof can easily withstand even strong winds, so it can be used in areas with a rather harsh climate.

The rafters themselves can be rigid or movable. The tough option involves the lack of the ability to move the rafters. The movable connection, on the contrary, allows the rafter leg to move along any line. For this, special fasteners are used.

Building a roof for a house made of wood is not an easy task, but if it is solved, then the construction will last a very long time, since it is the problems with the roof that are one of the most common reasons for major repairs.

Alas, no comments yet. Be the first!