Modern construction technologies allow the construction of various types of buildings, but the most promising option is roofs with several slopes. In the case when the building is built of wood, then deformations caused by shrinkage may occur, which means that a movable fastening will be required to maintain the strength of the roof. In such situations, a sliding support for rafters is usually used, which this article is devoted to.

Through the use of a compound with several degrees of freedom, a balanced design is obtained that can compensate for shrinkage and maintain the necessary strength to withstand snow and wind loads. Sometimes, these types of fasteners are also used in other situations when it is necessary to fix the elements so that they can move between themselves.

Mounts of this type can be used both in pairs or singly. The second option is preferable for areas where strong winds are rare and the mass of the roof is relatively small. In the case when the wind load on the roof is large enough, the fastenings are placed on both sides of the rafter legs.

Content

Production of sliding supports

These elements most often work in conditions of high humidity, and can also come in contact with condensate or water that has fallen under the roof slope. In order to avoid premature destruction of the metal, the sliding support of the rafters is made of steel protected by hot dip galvanizing.

The technology for manufacturing such fasteners is cold stamping. As a rule, low-carbon steel, for example, 08 ps grade, is used as a raw material. A small amount of carbon (0.08%) makes it easy to process this metal, and an increase in the strength characteristics of the finished product is carried out using the deoxidation method.

Types of sliding supports

All existing sliding supports can be divided into two categories:

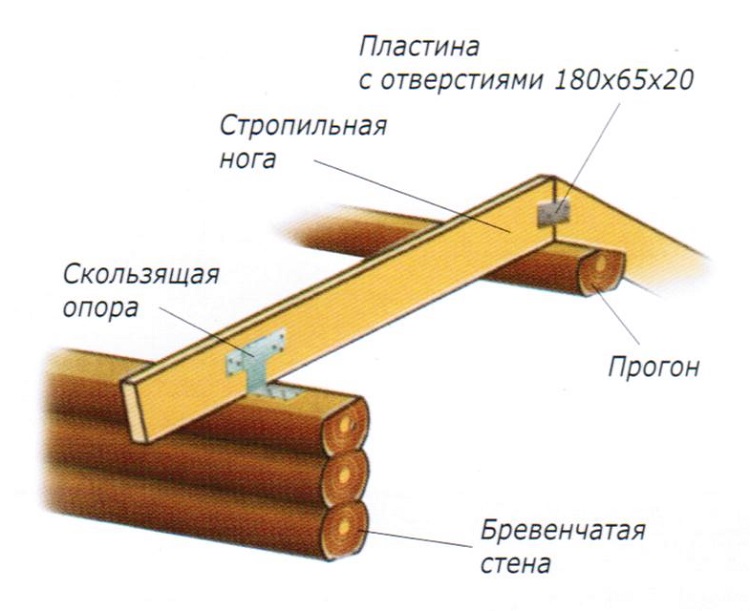

- Open type. This design is two separate elements. The first is the guide, which is attached to the rafter leg. It is a curved steel plate, the ends of which have holes. Depending on the manufacturer's company, their number may be 2 or 3 for each end of the plate. The stroke length of the movable element also varies. Its minimum value is 60 mm, and the maximum is 160 mm. Fixed part - the corner can have up to 5 holes.

- The railing sliding support is closed. Such supports are not disassembled into constituent elements and represent a single design. It is mounted already assembled. In this case, the fixed part is made in the form of a corner, the long side of which has a special holder into which the fastening strip is threaded.

To fix the plate in the case when a log is used instead of the Mauerlat, it is recommended to cut out a platform equal to the width of the L-shaped part of the sliding mount. If this moment is not taken into account, in the future the movement of the elements relative to each other will be difficult, and due to friction, excesses or damage can occur.

Operation of sliding bearings

Shrinkage of wooden elements is carried out due to humidity, temperature changes or other factors, however, all these reasons lead to the fact that the elements of the rafter system are set in motion, changing their position relative to others.The wall that is under the ridge settles the most, and the edges of the house, on the contrary, settle less.

Installation of sliding supports is carried out using self-tapping screws having a protective coating, otherwise they will become the weakest point of the entire structure, from which the destruction will begin. The sliding support for the rafters is installed so that the rafters can move freely in the direction perpendicular to the beam. To do this, cuts are made in the Mauerlat, which serve as guides and protect the movable structure from distortion.

Installation of sliding supports is carried out after the cuts are made in the Mauerlat, and the rafters are laid and fixed in the ridge. The choice of the length of the sliding supports is made in accordance with the estimated displacement of the rafter legs.

During installation, the guide rail is first fastened, which should be parallel to the rafter ribs, after which a fixed corner is fixed.

If the corner is attached to the Mauerlat by the insert method, should the depth not exceed? thickness of timber or log. Otherwise, the structural strength will be too low.

It should be noted that in addition to movable mounts, there are other ways to compensate for the shrinkage characteristic of wooden buildings. An example is the ridge connection, which is created in such a way as to allow the elements of the rafter system to move relative to each other. Of course, someone can say that they used to do without such elements, but the use of twisted wire is less convenient in installation, and in terms of reliability this option is somewhat inferior to the modern method.

Alas, no comments yet. Be the first!