The roof is a significant construction of any home. It, together with the roofing, is designed to reliably protect the building from the surprises that the weather presents to us. It is not surprising that she needs to pay special attention and, taking into account the particularities of the installation of all its constituent elements, carry out work in strict technological order. One of the important elements of the roof is the counter grill.

Many people and even unprofessional builders often take it for an ordinary crate. But there are differences in these two elements of the roofing cake, they are slightly different and perform different functions. Both components are very important and their presence is necessary for the construction and functioning of almost any roof. Therefore, briefly dwell on each of them.

Content

Distinctive features of lathing and counter lathing

Most of the materials that are attached to the walling of the roof are not installed directly on them, but with the help of an “intermediary”. This method of attachment is convenient because it allows repair work without special difficulties. Often it is negotiated as a prerequisite for the installation of the roof. With the help of such a specialized frame, many technical problems are solved, and the structural element itself has a name - roof lathing.

Most often it is used on pitched roofs. The material for it, as a rule, is wood, but metal structures can also be used.

So what is a crate? This is a series of boards that are nailed to the rafter system (on it, in turn, a roof covering is attached). It can be of two types: continuous and discharged.

In the first case, a gap of less than 1 cm is made between the boards. Such a roof is mounted in two layers:

- the first layer is discharged;

- the second is made continuous using moisture-proof plywood or oriented particle boards laid in relation to the first layer at an angle of 45 degrees.

A continuous crate performs additional sound and heat insulating functions.

A continuous crate is performed under roofs having a small angle of inclination of the roof slope:

- soft tiles and metal tiles;

- asbestos flat slate;

- asbestos-free flat slate.

The discharged crate is used on roofs covered with steel and corrugated sheets, clay and cement-sand tiles.

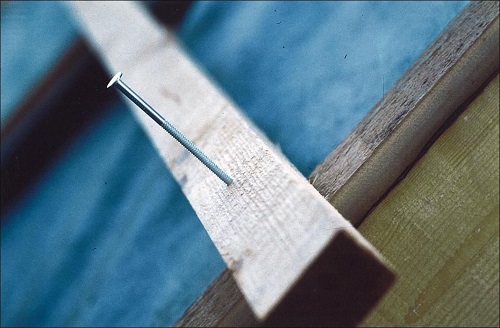

The installation of the crate is carried out using a beam measuring 50x50 or 60x60 mm. To the counter-lattice, the lathing boards are nailed with nails with a length equal to the double thickness of the bars.

Wooden bars are usually called a counter-lattice or counter bars, which are stacked directly on the hydro-barrier material to the rafters.

They mount it with the goal of providing ventilation for the waterproofing layer, which can be different materials - films, roofing felt, hydro-barrier membranes.

Carrying out a counter-grill for a metal tile, they want to create a ventilation duct that would separate the crate, waterproofing and finish.

During roof operation, condensation often forms on the inside of the roofing. With a large amount of condensate moisture, rotting of the wooden elements of the roof structure may begin.

The counter-lattice, which, first of all, is arranged as a frame for the lathing, simultaneously provides an influx of air currents that remove excess moisture.

Counter bars are made using workpieces having a cross section of 30x50 mm. For roofs with complex geometry and long rafter legs, workpieces with a cross section of 50x50 mm are used.

Installation of counter-lattice

When installing all types of pitched roofs, it is recommended to make a counterbasket. As already mentioned, the counter bars are nailed along the rafters directly onto the waterproofing material. In this way, the structure of the lathing is raised to the height of the beam, which, in turn, provides effective ventilation of the roof space. The height of the counter-lattice ranges from 2-5 cm.

Install the counter-lattice already after a layer of waterproofing material is laid on top of the rafters. Until recently, roofing material was mainly used in this capacity. Currently, more advanced materials are used in this purpose, which are distinguished by better quality and reliability. We are talking about membranes and waterproofing films.

The counter-lattice is stuffed after the fixing of the waterproofing to the roof rafters is completed.

We want to note some important points in the device of the counter bars:

- On roofs with a slope of 30 degrees, bars are used that have a cross section of 25x50 mm. When the counter-lattice is arranged on roofs with a lower slope, it is not recommended to save on material.

- The fixing of the counter bars with a length of 135 cm and a thickness of 30x50 mm on the roof rafters is carried out with a step of 300 mm. This is done using galvanized nails.

- In the case when during work on the waterproofing device there is a need to move around the counter-lattice, then a draft crate should be mounted.

The development of counter rails in the field of valleys and skates deserves special attention:

- During the correct installation of the skates, the intersection of the upper planes of the counter bars should occur at one point. This can be achieved if the bars of the counter-lattice of the opposite slopes are filed at the required angle. If the installation of the crate is correctly made in the area of the ridge, this will contribute to the accuracy of calculating the pitch of the bars of the crate and the laying of the upper row, for example, of tiled elements.

- In the area of the valleys, the main counter bars are nailed to the longitudinal bars of the valley or ridge. They do this with a step of 10 cm. This design allows you to freely remove dust, condensate, snow, as well as produce effective ventilation of the roof space under the roof covering.

When installing a counter-lattice for valleys, an error is often encountered when during the installation process the bars are laid tightly to the valleys. With a distance between them and the support of the valley of 5-10 cm, a free flow of water will be ensured. When the bars are tight, there is a significant deterioration in the ventilation of the valleys, since it is difficult to remove condensate through the eaves.

In addition, the debris will accumulate construction debris, which is invariably generated during installation. At the same time, the counter-lattice from the ends under the influence of moisture will deteriorate. When flattened gates are arranged, sealing tapes are used as counter lattices, which help to eliminate leaks.

If you do not adhere to the above recommendations, the construction of the ridge and valleys may be disrupted over time.

Fixation of waterproofing with counter bars

It must be taken into account that the fastening of the rails on the waterproofing material is carried out using nails, which are 1 square meter. A meter can be about 10 pieces. And this means that in these places tightness is broken and moisture can penetrate, especially in rain.This situation arises at a time when workers did not have time to install a crate and a finish on the counter-lattice.

Such leaks are temporary. They disappear as soon as the roofing material is laid. Moisture that gets into the roof structure will surely disappear, since the space under the roof is well ventilated.

The material for the counter-lattice is oak or pine, which is used for roofs with a large weight. For light coatings, softer grades are used.

The device of the lathing under the soft roof

Currently, soft roofs are especially popular. The base or crate for a soft roof is an important detail of this type of coating. It is made in two layers so that the resulting coating is continuous.

After completing the first layer, a smooth layer is laid on it and bends and friction of soft tiles are not allowed. That is why it is more correct to start installing the lathing from the frame itself.

After the crate is installed on the frame, a layer of roofing plywood is laid on it, which is pre-impregnated with a special waterproofing composition. After completing all these works, we can assume that the crate for the soft roof is completely ready and capable of performing the functions assigned to it.

Slate lathing device

For this type of coating, the crate for slate is made of two types - single-layer and two-layer. The first is laid on the rafters in increments of 0.5 - 1.0 meters parallel to the ridge. However, a continuous crate is more common when the boards are nailed onto dry boards previously soaked with an antiseptic.

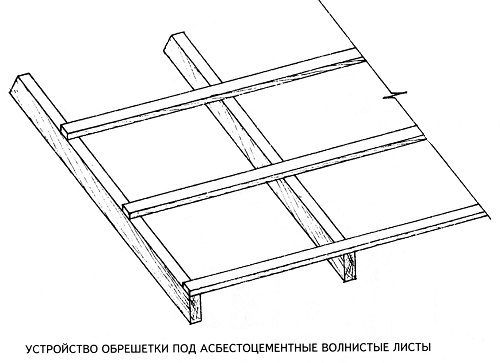

This crate is correctly made of wooden bars in a position across the rafters. When roofing from ordinary wavy sheets, the distance between the bars of the crate should be half a meter.

With a wavy uniform profile, the pitch should be 0.8 meters. In the first case, the cross-section of the beam is 50x50 mm, and in the second 77x75 mm.

The crate for the slate provides that the support of each sheet of slate falls on 3 beams. The cornice beam is either made much thicker, or it rises to a height with the help of special gaskets.

In order to maximize the tight overlap of the sheets, the odd bars make 30 mm thinner than the even ones. This measure allows you to evenly distribute the load on each slate sheet.

Solid wood flooring is done on roof elements such as skate, overhangs and grooves.

Overlapping of sheets is made from bottom to top and, as a rule, from right to left. The top row 12-15 cm should overlap the bottom. The overflow can be changed in the direction of increase so as not to cut the sheets, while choosing the entire distance from the overhang to the ridge.

It is recommended that you first make the overhang of roofing steel, and then lay the slate sheets. They are fixed on overhangs using anti-wind steel brackets.

In the case when the roof structure has an inclination of 30 degrees in places of overlap, the sheets are laid on a special mastic.

The device of the crate for ondulin

The crate for ondulin is carried out according to the following rules:

- In the case when the angle of the roof slope is in the range of 5-10 degrees, the crate is made in the form of a continuous flooring from boards or moisture-proof plywood. The overlapping of successive rows is made in 300 mm, and the lateral overlap is carried out with an overlap of two waves.

- When the angle of inclination of the roof is 10-15 degrees, then the crate of beams of 45x50 mm is arranged parallel to the cornice with a pitch of 450 mm. The overlap of the ondulin sheets, which are located in successive rows, is 200 mm, and the lateral overlap is in one wave.

- When the angle of inclination of the roof is more than 15 degrees, the crate is also made of beams of 45x50 mm, but with a step between the axes of the beams of 600 mm. The upper row is stacked, making an overlap of at least 170 mm. Lateral overlapping of sheets is made in one wave.

- When it is necessary to withstand a certain interval between the bars of the base, the crate for ondulin may need to use a wooden template.

- In the places of fastening of the roof ridge and valley, additional bars of the crate are installed. In places of vertical contact of roofing sheets, installation of a board 50x100mm is carried out.

The device of the crate for siding

Such a facing coating as siding is widely used in the decoration of buildings. It is a set of panels made of wood-polymer composites. The preparatory work that precedes the installation of these panels also includes the installation of a crate for siding.

It is a frame made of aluminum or wood, which is installed on the walls of the building in front of the siding. When the walls are so even that they do not have bulges and bevels, the use of the crate is not necessary - in this case, the panels are mounted directly on the wall. True, this installation method cannot be attributed to reliable and durable.

Wooden crate is preferred due to its low cost. The bars are pre-dried and saturated with antiseptic substances that prevent early decay and protect against insects. Other impregnations protect the bars from the effects of fire. Apply rails that have a cross section from 30-40 mm to 50-60 mm. The length of the bars corresponds to the length of the wall, and the width is two distances between the mounting grooves.

Installation of the battens for siding is carried out along the perimeter of all walls of the building, the basement and on the openings of windows and doors. Reiki, depending on the area of construction, are located at a distance of 20-40 cm. From the wall, the frame moves 20-60 cm, which allows filling the space with heat-insulating material.

Wooden beams are often replaced with galvanized metal profiles. Compared to wood, they are stronger, do not need special processing and leveling. They are easier to mount on the wall surface.

The crate is always located in the direction perpendicular to the location of the siding. If the siding panels are placed horizontally, then the profiles or bars will be placed vertically. Installation begins with “beacons”, i.e. extreme lattices along which a longitudinal row of bars is built. The correct location of the crate can be checked by the building level.

Victor

Now I see my mistakes, thanks for the site.