For many years, metal roofs have enjoyed steady popularity. They are distinguished by reliability and high service life. Other positive aspects can affect the choice in favor of this material, including low cost, the ability to produce sheets of any thickness and shape, versatility. But the lack of colors can easily be corrected independently, using the tips for choosing paint for a galvanized roof.

Why do I need coloring

Manufacturers of galvanized sheets, of course, apply a protective layer in the form of oil, but, unfortunately, it can come off after a year, exposed to atmospheric influences. Therefore, after this period, it is best to coat the metal with special paint. This will avoid the following problems:

- When exposed to atmospheric precipitation, rust is often observed, and this is the first sign of the destruction of a galvanized roof.

- Improving the appearance of the roofing. Staining will help make the roof more suitable for the overall style of the house.

- Painting a galvanized roof is quite expensive, but it will still be cheaper than replacing it.

Under the condition of improper storage of the metal, water accumulation may occur, during the evaporation of which “white rust” often appears, which is a powdery white spot.

Paint selection

The paint will help not only make the coating more attractive, but also increase its service life.. You need to choose the material, focusing on the increased passivity of the metal surface. Effective elastic and adhesive properties - these are good qualities of paint for a galvanized roof. It is worth abandoning alkyd and oil. They are not suitable for our purposes because of their chemical reaction that occurs in the process of interaction with the metal, which leads to a decrease in adhesive properties. For this reason, such coatings can quickly peel off from the galvanized roof. They will last only one season. This is not only unprofitable from a material point of view, but also will lead to additional labor costs.

The most reasonable choice is to use a special paint. It is worth paying attention to acrylic primer-enamels. Justifying their high cost, they protect the galvanized roof for a long time, increasing its life. An additional bonus when applying primer-enamel will be an attractive appearance, unlike oil paints.

Consider the advantages and disadvantages of the most popular galvanized roof paints on the construction market today.:

- Hammerite. She has:

- the possibility of applying directly to rust;

- the creation of a wear-resistant coating that can last a long time;

- excellent grip with a metal coating;

- excellent anti-corrosion properties;

- excellent appearance of the roof;

- quick drying;

- a variety of colors;

- resistant to ultraviolet radiation.

But it’s worth considering:

- the possibility of the formation of salt deposits;

- the manifestation of rust after three to four years;

- Inadequate degreasing may cause cracks in the paint;

- When using the paint roller, air bubbles may appear.

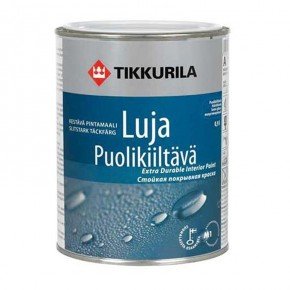

- "Tіkkurila". The positive properties of her are the same as that of the previous paint, but as an addition to the advantages, one can also name:

- good resistance to weathering and chemical environment;

- heat resistance (up to +80 degrees), so it can be used in hot weather - this condition will even improve the adhesion of the paint to hot galvanized steel;

- storage and transportation at low temperatures are possible.

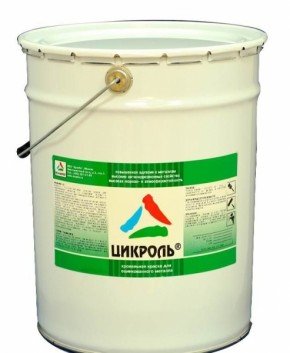

- "Tsikrol" - matte acrylic paint:

- it includes anticorrosive substances;

- it will help protect the galvanized roof from weathering;

- quickly adheres to metal and is evenly distributed on the surface;

- does not require a primer of galvanized sheets before application, because they are applied in one layer.

- does not fade;

- characterized by quick drying;

- hardy.

- "Unicom" - fire retardant paint. It will guarantee galvanized coating protection against accidental ignition.

- Serebrol is a one-component anticorrosive enamel. It is used for a galvanized roof or ferrous metal:

- Its main component is aluminum powder. It allows you to increase the protective properties, creating a barrier effect.

- it also contains epoxy and perchlorovinyl resins, a mixture of organic solvents and anti-corrosion additives;

- differs in high anticorrosive properties, resistance to atmospheric influences and wear resistance;

- characterized by oil and gas resistance and thixotropy.

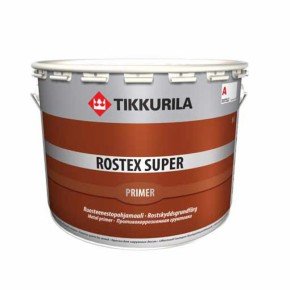

- Rostex Super is a special primer for galvanized roofs. It is well used to cover ventilation and drainpipes;

- "Passarimaali" - paint, which incorporates anti-corrosion components, is suitable for any metal construction. Consumption will be a liter per ten square meters of surface.

You will also need reliable tools to work.

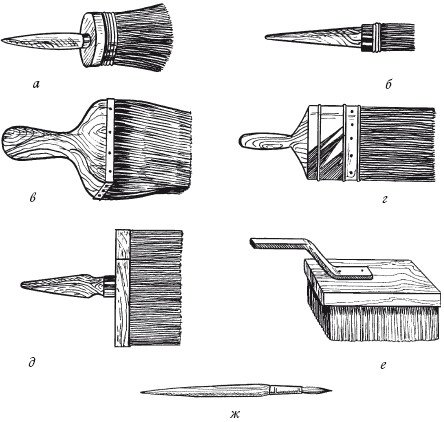

The use of the brush will ensure a good application, and its high quality will help to avoid hair loss. The painting tool should have a width of 75 mm or more.

Roof preparation

Whatever paint you choose, preparatory work must not be neglected:

- First you need to check the condition of the roof for rusty areas (some paints are not suitable for use on such surfaces), which must be replaced or cleaned with kerosene;

- Cracks and holes must be repaired with a soldering iron, special sealants or adhesives;

- Old paint must be cleaned, if, of course, it was applied;

- Clean the roof of dirt, salt, grease and other debris. To do this, first you need to sweep it, and then wash the surface. Dirt and grease can be washed off using alkaline solutions, such as washing powder, and the residues can be washed off with water;

- An important step is degreasing. This will ensure better adhesion of the paint to the surface;

- Sometimes for some paints it is necessary to primer the surface.

For painting the roof, cloudy, dry weather with a light wind is best suited. Working in the evening can lead to dew, which will spoil the surface covered with paint. To ensure its drying, the air temperature should be more than five degrees, and humidity should be below 80 percent.

The nuances of painting

Having eliminated all the defects and letting the galvanized roof dry, we proceed to painting. You can apply paint using a fly brush, roller or spray gun. When using acrylic primer-enamels, they are applied in two to three layers.

Renovation of coatings is usually carried out every eight to ten years, but a condition check should still be carried out periodically. This will prevent moisture from entering the resulting cracks, which can lead to rust formation. If this happens, then these areas are again covered with paint.

To enhance the staining efficiency, two types of primers can be used.. First, the surface is primed with a fleecy roller with a long handle. For hard-to-reach places, such as the seam of panels or screws, you can use a brush. It is important not to miss a single site.Next, you need to wait until complete drying, after which another layer of primer is applied, which has anti-corrosion properties. This method using primers of various kinds will eliminate the appearance of peeling on the paint. When the second layer is dry, go to the final stage - applying two or three layers of acrylic primer-enamel.

Alas, no comments yet. Be the first!