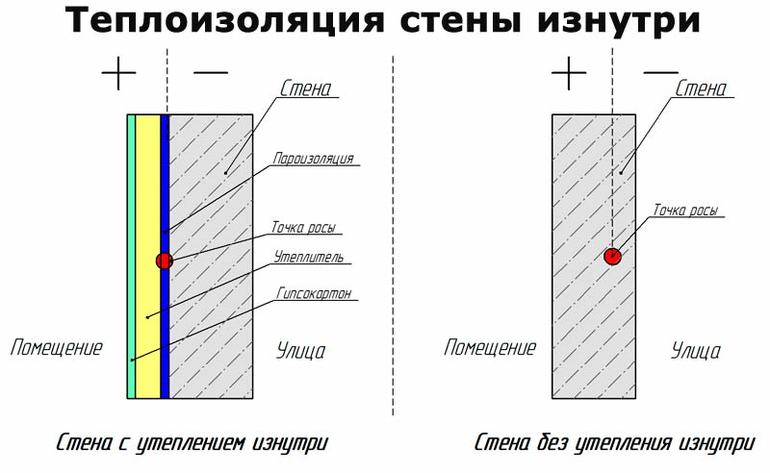

Insulation of the house from the outside helps to save heat indoors and create a cozy and comfortable atmosphere for living. But sometimes it is impossible to do this, so you have to carry out wall insulation from the inside. To prevent the formation of fungus in multi-storey buildings, it is this method of thermal insulation that is used.

Content

Types of thermal insulation materials

There are many inexpensive insulation materials on sale. Each of them has its own characteristics, which allows you to choose a heater for any surface. To insulate walls from the inside, the materials use the following:

- Polyfoam and foam. These are effective and inexpensive materials that are easy to install without the use of a professional tool. They are used for insulation of apartments in high-rise buildings, as well as structures made of foam concrete, brick, concrete. Since these materials do not pass air well, they are not used for wooden structures. Disadvantages: brittleness, increased combustibility, vapor impermeability. So that the apartment, insulated with foam or polystyrene, does not turn into a greenhouse, it is better to install working ventilation.

- Mineral wool. This is a non-combustible material with not only heat-insulating properties, but also sound and vapor barrier. It is used for wall insulation inside the house, in production, as well as as a filler of drywall partitions in rooms. Since mineral wool has the ability to accumulate moisture, it is not worth it to insulate walls subject to periodic dampening. The first layer of waterproofing is laid and only then mineral wool.

- Foil Insulator. It consists of foamed polyester and an aluminum foil layer that reflects heat. The material is easy to use, thanks to a self-adhesive base.

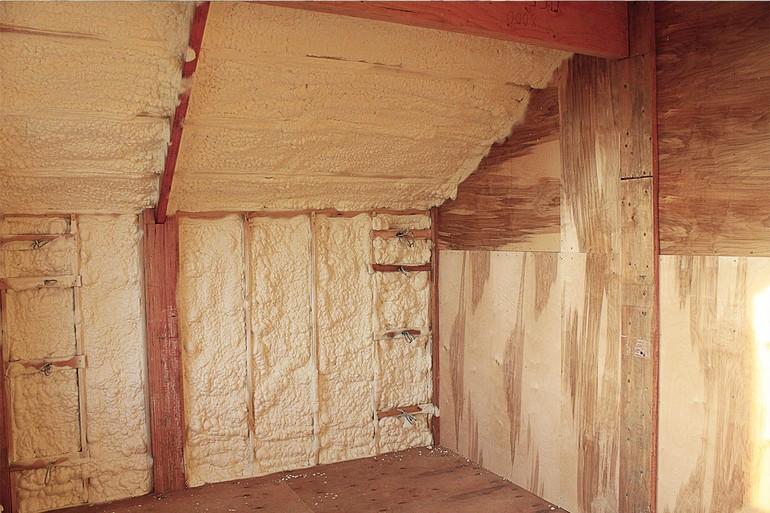

- Ecowool. Natural and safe heat insulator based on recycled recycled cellulose. Ecowool has a fine fiber structure, non-toxic, does not shrink. For its installation, special equipment is necessary, so there is no way to carry out the work yourself. When warming the house from the inside with ecowool, it is necessary to build a wooden crate. It will hold the material on a vertical surface, preventing it from sliding.

- Glass wool. The material has an affordable price and is widely used in construction. It is made on the basis of fiberglass, flexible, has high sound and air insulation properties, flame retardant. Disadvantages: it is subject to shrinkage, under the influence of ultraviolet rays it is destroyed, subject to mechanical stress, the warranty period is not more than 10 years.

The choice of insulation for the internal walls of a private house depends on personal wishes and financial capabilities.

Methods for insulating walls from the inside

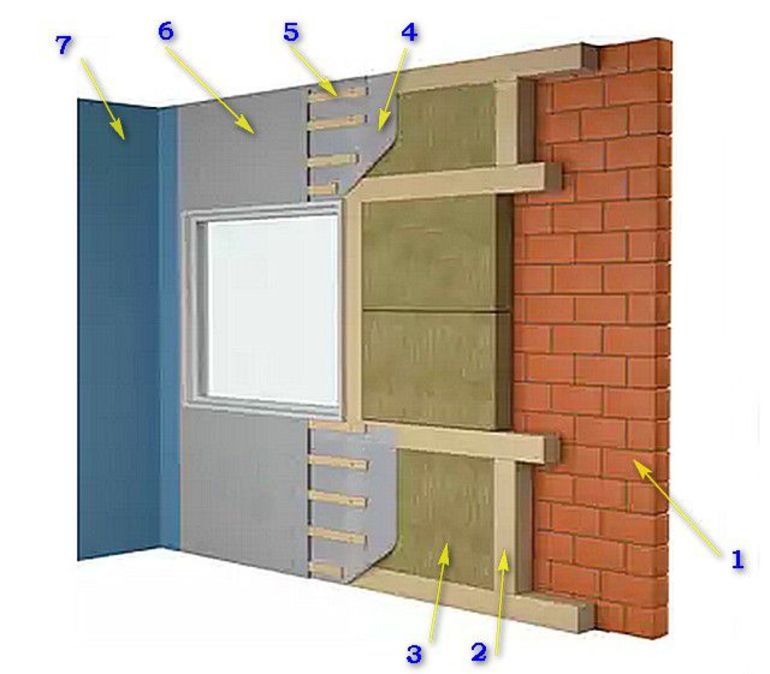

In order to properly make internal thermal insulation with your own hands, you need to choose a method of insulation. This can be done in 2 ways: on the frame and on the glue. But experts recommend that such work be carried out only if it is impossible to do this from the outside of the building.

Frame mount

If the foam is selected as a heater, then its installation is done on a frame that protects the material from mechanical influences. Work order:

- During installation, alignment of the wall is not required. It is enough to remove exfoliated plaster from the surface and clean the dirt.

- On top you need to apply an antiseptic substance.

- The frame is preferable to assemble on the basis of bars or profiles with a step of racks corresponding to the width of the material. For foam, the distance between the posts is 60 cm. When laying a soft insulation - 58 cm. Self-tapping screws or dowels are used as fasteners.

- The heat insulator is placed in the cells of the frame, and the seams are filled with foam. The final finish is carried out after the foam completely hardens.

In addition to polystyrene foam, glass wool, wood fiber, balsamic insulation can be attached to the frame.

Glue mounting

Not all types of insulation can be mounted on glue. For this, only dense material is used. Installation is as follows:

- Before insulating the walls of the house from the inside, they must be carefully leveled, putty all cracks, cleaned from dirt and degreased.

- Additionally, the surface is treated with an antiseptic, 2 layers of soil are applied.

- The insulation is mounted after the walls have completely dried, having previously lubricated it and the material with glue. After three days, when the glue is completely dry, the insulation is additionally strengthened with dowels.

Before installing the insulation, it is necessary to waterproof the base. And after installing it - vapor barrier. Finishing work is commenced when all thermal insulation work is completed.

Alas, no comments yet. Be the first!