The solar battery is a device that allows the direct conversion of solar energy into electricity. DIY panels are often inferior to factory models. The current strength of one photocell is equal to hundredths of an ampere. To obtain sufficient power, the photocells must be combined into interconnected modules. Creating a solar panel with your own hands is a simple but painstaking task.

Preliminary calculations

The average electricity consumption per family per month is 300 kW. Per day consumption is 10 kWh. Solar radiation is most intense between 9 a.m. and 4 p.m. If during these 7 hours you get 10 kW each, the module power will be 1.43 kW. Such an amount of energy can be obtained only under ideal conditions. Below are the data, guided by which you can easily calculate the number of elements and sizes of the solar panel of the required power.

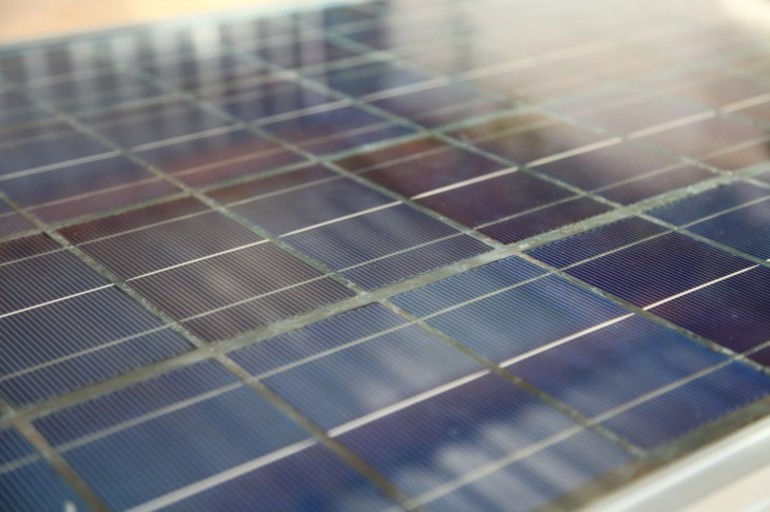

The dimensions of the panel depend on the required voltage and power. Polycrystalline cells 3 × 6 inches (7.6 × 15.2 cm) in size are suitable for creating a solar battery in their properties and availability. Such items are freely available. on many internet marketplaces. It is better and cheaper to purchase category B modules - products that have minor chips and damage. The service life of polycrystalline cells is 25 years.

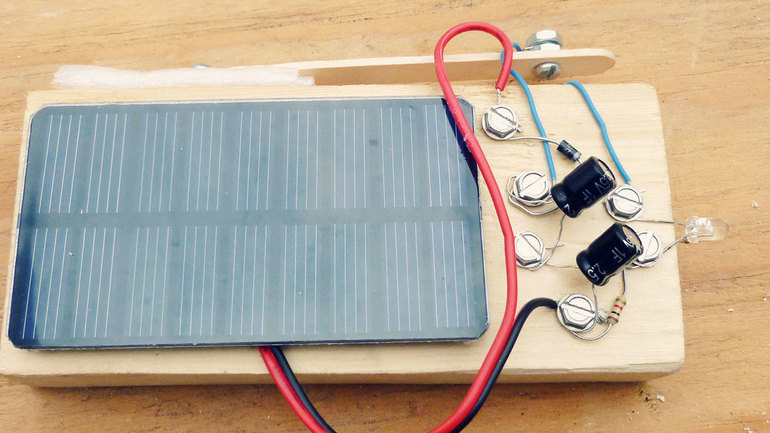

One such cell produces a voltage of 0.5 V. To get a collector for charging a mobile phone, you need 9 of these modules.

To make a solar battery you need to cook:

- 9 photocells.

- Copper wire (stranded).

- Transparent material with anti-reflective coating.

- Wooden beam 3 × 3 cm.

- Sheet of plywood and fiberboard.

- Sealant.

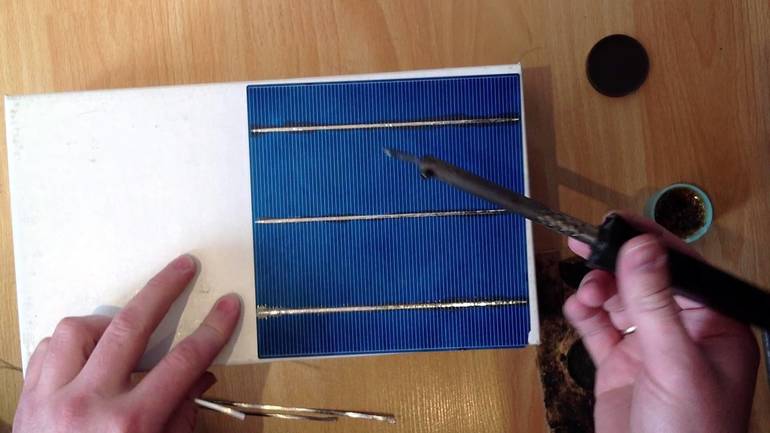

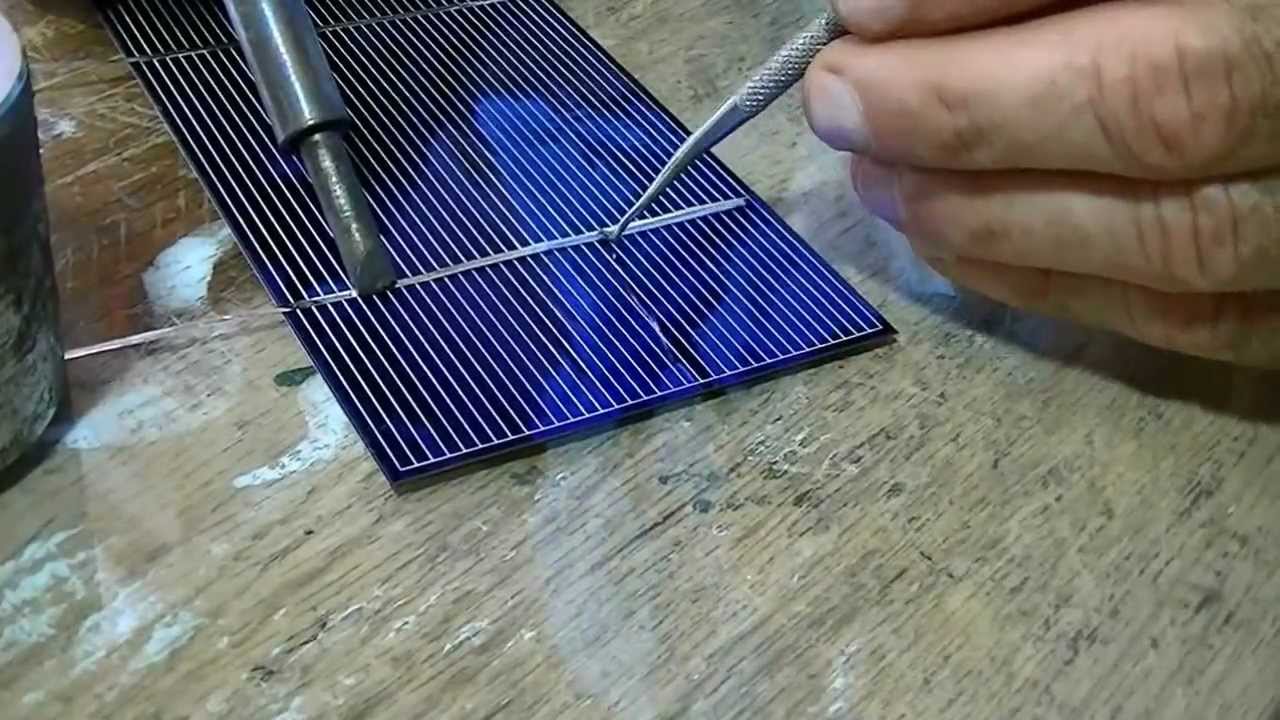

Of the tools should be stocked with a soldering iron, screwdrivers and a saw. For soldering, it is recommended to use a soldering iron with a capacity of not more than 40 watts. This will help to avoid overheating of parts.

Battery manufacturing process

The process of manufacturing solar panels should begin with the manufacture of boxes for the future device. Its dimensions: 7.6 × 15.2 × 9 cm, which corresponds to 1.04 m². This is the internal size of the structure. It is necessary to make a frame of timber and attach on one side a sheet of plywood with drilled ventilation holes to fit the frame. To cover wooden details with a varnish or paint for protection against influence of external factors.

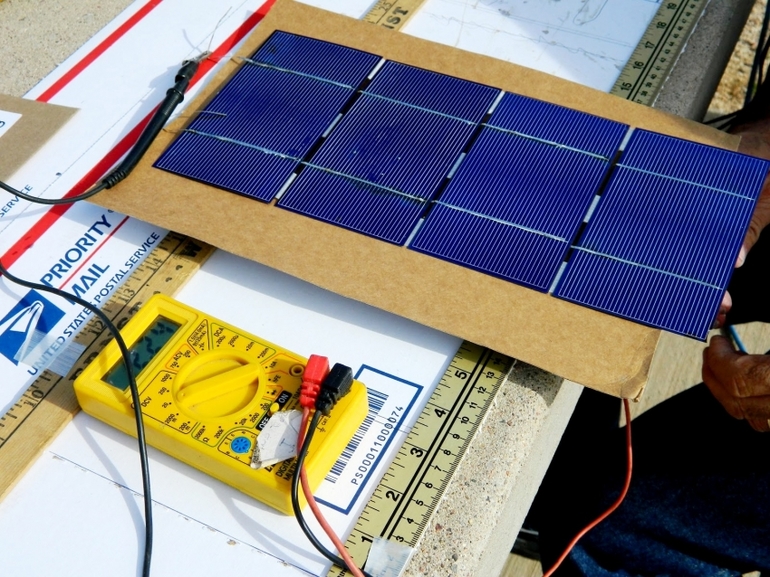

Now the solar cells must be assembled in one design. It is most convenient to assemble on a pre-cut fiberboard sheet. Cells should be placed one below the other. Only then can you start soldering them into a common block. Each photocell is connected to the other in sequential order.

After connecting the parts, it is necessary to leave the conclusions of the copper wires for further connection. Apply sealant to the resulting block and press it against the fiberboard substrate. In the manufacture of a solar panel do it yourself laying and soldering work should be done with extreme cautionbecause the battery modules are very fragile.

The finished structure must be laid in the prepared box and secured with screws. Using the same parameters, cut out the glass, which will be mounted on top of the photocells. Carefully apply a layer of sealant around the perimeter of the frame and glue the glass. The assembly of the solar panel is completed.

For output, it is advisable to use wires with different colorsso as not to confuse plus and minus. It is better to install the structure on the ground, choosing a place where the nearest buildings and objects do not cast a shadow. This will facilitate maintenance during operation.

The general scheme for connecting the solar module to consumers is as follows. The electric current from the battery through the charging controller enters the accumulating elements, from which it passes to the inverter, converting to the desired voltage, and then feeds household appliances. This scheme is used for large power solar panels. In simpler cases, it is enough to connect the module to the battery or to the consumer directly.

Making solar panels at home is a doable task. However, a home-made panel will be inferior in all characteristics to analogues produced by large enterprises or factories.

Sergey Anoschenkov

Nothing but a guide to masochism .... and obviously not a permanent street option.

Alexander

“Its dimensions: 7.6 × 15.2 × 9 cm, which corresponds to 1.04 m².”

This is how the volume turned into an area ???

Oleg

He was engaged in a similar topic. It is cheaper to buy ready-made from the same Ali.

ALX666

... it remains to lay out the instructions - how to remove the appendix yourself

Alexei

It is better and cheaper to make a solar reflector by focusing the reflection of sunlight on a tank of water. The resulting steam should be directed to the turbine and immediately generate alternating current from the generator. It can then be straightened and stored in batteries if you want to spend money on batteries. On non-sunny days, you can also just heat water with wood, coal, gas, fuel oil and get electricity. Of course, any system requires maintenance costs (repair), but this one will be the cheapest system. While there are no real BTGs (fuel-free generators) and even if they appear, their maintenance and repair are still required.