During construction or other land improvement work, holes in the ground often need to be prepared. Such pits are necessary for the construction of light household structures and structures - arches, fences, etc. The TISE drill can be used in individual construction to prepare a pile foundation, it is more difficult to make it than making a drill for drilling holes under poles, but there are enough drawings.

Content

Using a Hand Drill

The main task of the drill for home and professional use is the preparation of holes in the soil of a given diameter. This method is much easier to use than preparing the onions with a shovel and then backfilling the excess space. For example, when preparing a well for water intake, the use of a shovel is completely unsuitable. This is due to the fact that the depth of the aquifer is far and such work cannot be done without a tool. The drill at home is also used for such purposes:

- pile foundation casting;

- preparation of holes for planting vegetation;

- deep loosening of the soil;

- digging straight and sloping tunnels;

- compost pit preparation.

A feature of such a tool is its simplicity of design. If necessary, make such a design at home, the process takes almost no time. The list of main parts includes - the central (axial) rod, blades and handle. However, depending on the intended purpose, structural modifications are possible - a spoon-shaped drill with a split pipe or TISE.

Some craftsmen make a fully collapsible drill, in such cases, you can change the diameter of the hole simply by fastening parts of a different size.

Tool making

Hand drill can be made at home from metal parts. Depending on the intended direction of its application, you can choose different options. If you intend to drill a deep well for water with a manual tool, you need a detachable drill pipe, and you can make a drill for drilling holes under the posts with your own hands according to a simplified design:

- The circular saw blade is cut into 2 halves and welded at different angles to axial reinforcement or pipe from different angles.

- The tip of the axis is sharpened in the shape of a spear, if the pipe can be welded an old drill of the corresponding diameter or flattened.

- The handle is welded on top of the axial column of the same material or fixed in a welded ring.

The cutting edges of the working part of the drill can be sharpened and hardened in a muffle furnace. As an alternative, you can make a spiral drill. In order to weld several cut steel circles in a given shape. At the ends of the resulting spiral, they are mounted in a ring and the resulting spiral is stretched along the pin. In this position in the center it needs to be welded.

Do-it-yourself spoon-shaped drill

A spoon-shaped drill for the preparation of mines or wells is used in areas with loose and easily crumbling soil. The shape of the working part resembles a cylinder - inside the soil accumulates during drilling. The length of the drill part of the tool is not more than 70 cm, with a diameter of the intended hole.The easiest way for the working part in the manufacture of such a drill is to use a finished steel pipe with a diameter of 15-20 cm, depending on the expected diameter of the well. Additionally needed:

- angle grinder (grinder);

- electric welding machine;

- axis from reinforcement or pipe;

- old thick drill for metal;

- 2-3 metal cuts 3-5 mm thick.

As a replacement for the pipe, you can use a used gas cylinder or rolled steel sheet.

At the end of the steel pipe, slots are made on opposite sides. The cut parts must be bent so that the angle between them is obtained, as in the propeller. The edges of the cutting elements are sharpened. An axle mount is welded in the middle at the top. The rod or wheelhouse for the axis is located inside the drill part and welded. To release the tubular drive of the spoon-shaped drill, you need to make a longitudinal section with a width of 3 to 6 cm.

Making a pen for a drill

In the manufacture of a drill for household chores do-it-yourself need to consider the design features of the handle. The simplicity of using the tool and its capabilities when drilling different types of soil at different depths depends on this. The handle and the upper part of the axis are recommended to be joined by welding or to make an annular connection.

The length of the handle must be determined by the estimated effort and number of people when drilling. If it is short, then it will be possible to work only one, and the depth of drilling will not exceed 1.5 meters. In the case of the removable option, there is no difficulty in building. As a material for the manufacture of the handle of the drill, you can use rebar or old scrap.

Split type drill pipe

The detachable drill pipe is a type of axis for a hand drill. This structure allows, if necessary, to increase and reduce the depth of the well. If 1.5 m is enough to install a support pillar for a fence on a garden plot, then a great depth is needed when preparing a well. Split pipe - the ability to make a universal tool. To make such an axis you need to take into account a number of nuances:

- The length of each individual element is not more than 1 m. Thus, the tool will be more compact during transportation.

- The connecting element should be simple and reliable, since the drill needs to be lifted to remove the soil.

- When using a detachable pipe, the handle must be removable to allow attachment to any section.

The easiest way to secure individual elements is by welding the coupler on one side on each section. To fix the joints, prepare holes for the bolts. With increasing drilling depth, it is enough to disconnect the handle, insert the next section and fix it with a bolt. The handle is then put in place and drilling continues.

It is better to choose sections no more than 1 m, so during assembly it is possible to measure the depth of the shaft and calculate drilling by the number of elements.

The structure of the drill TISE and method of its manufacture

TISE is a technology by which mines are prepared in the ground for further pouring the pile foundation. Such a hole in the ground along the upper part corresponds to a classical cylinder, but at the base it is expanded. The foundation cast by this technology is durable and lasts longer than the classic. Piles cast using TISE technology are distinguished by the following qualities:

- low price with high stability;

- the possibility of casting on different soils;

- speed of preparation of supports during construction;

- resistance to sharp and smooth temperature changes.

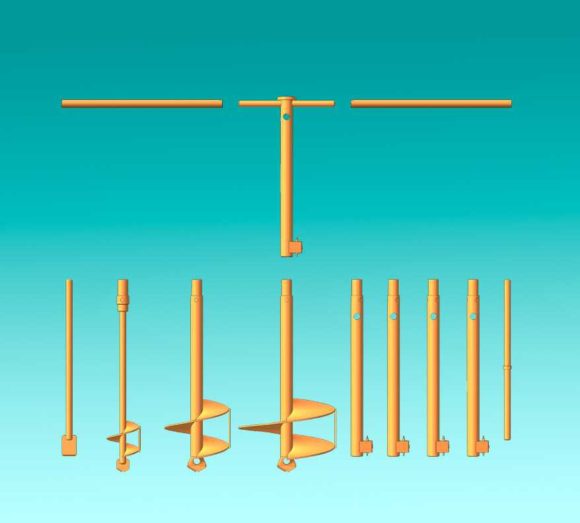

To make a TISE drill with your own hands, you need to prepare a pipe with a diameter of at least 15-20 cm. A long segment is not needed - this part will act as a drive for removing soil. It is better to use reinforcement 1.5-2 cm thick as the central axis. In addition, you need to take the workpiece on the side plow and the worked blade of the circular saw along the diameter of the pipe.The assembly procedure of the TISE tool according to the drawings is as follows:

- The drill axis at the end is sharpened in the shape of a spear or an old drill is welded in diameter.

- At a distance of 15-20 cm from the lower end, the halves of the disk are welded at an angle relative to each other.

- It is necessary to weld 2-3 plates to the fittings, based on the diameter of the drive. The axis is located in the middle.

- The drive is put on a resistant design, with the calculation of the location of the cutting part inside.

- On the axial part, slightly above the drive, an eye is welded for threading the cable from the plow.

- On the upper part of the pipe also have 2 eyes for fixing the side plow.

- The plow must be mounted so that it can be freely released to the side and pulled back to the axis.

To the finished structure in the upper part, a connector for the handle is attached or completely welded. On the handle for rotation, you can place a loop for the plow cord, which will simplify its fixation in the inoperative position. If you plan to drill holes deeper than your height, it is best to choose a split drill pipe option as an axial element.

To extend the life of the tool, it is recommended to clean the metal surfaces, degrease and coat the TISE drill with anti-corrosion paint.

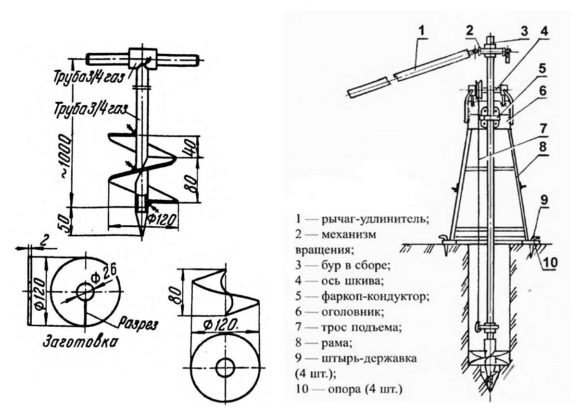

Shock-rope technique

Drilling a hole in the ground for a well or for installing a column can be not only a rotary type tool. To perform similar work also apply the shock-rope technique. Drilling work in this way can be done independently, and the depth may be suitable for the well. A drilling rig can be bought or made from improvised materials. It consists of the following parts:

- a tripod 2.5-3 m high;

- projectile (flap);

- cable;

- winch.

The principle of operation of this technique involves dropping a tubular projectile in place of the well. Due to its own mass, the bailer enters the soil and captures it. At the lower end of the working part of the installation there is a valve that holds the soil produced from the well. After removing the projectile, it is deployed with a technical hole down and the accumulated soil is shaken out by blows of a heavy tool - a hammer or crowbar.

Manufacturing installation

To prepare the drilling rig for the shock-rope technique, you need to put a high tripod at the drilling site. It is made of high strength metal, but it is recommended to make struts. At the top point of the tripod, a cable block is attached, it should be designed for the maximum mass of a shell filled with wet soil, taking into account a stock of about 50 kg.

To remove the bailer from the hole in the soil, you need to use a winch with a cable. They are also selected based on mass. It is fashionable to use a manual or automatic winch for drilling, but the fasteners must match. To fix the lifting device, an object that is larger than the mass, and loaded with soil, a projectile or a static object, for example, a tree, is suitable.

The structure of the flap

Zhelonka - a tubular projectile for shock-rope drilling. The main part contains the soil worked out while drilling the well. For capture, in the lower part of the projectile, a flap or ball type valve is made. The distance from the cutting part is not less than 5-7 cm. The diameter of the billet for the bobbin should correspond to the estimated size of the well.

The depth of the well with the shock-rope method of drilling increases by 40-50 cm in one approach. But, it is not worthwhile to focus on this parameter with independent manufacture of the bailer.

The drilling speed depends on the mass of the working part of the tool. To increase that parameter, it is recommended to place a load at the top of the projectile. As such, use pancakes with holes in the middle or fill the upper part of the choke with lead. When pouring along the length of the workpiece, it is necessary to take into account the place with the partition. The manufacturing algorithm of the bobbin is as follows:

- In the upper part of the pipe along the axial line you need to position the cable fastener.To do this, weld a transverse strip and drill a hole in it along the diameter of the cord used.

- The lower end of the pipe must be sharpened. Depending on the softness of the soil, you can choose the ring type (for hard soils) or toothed (for loose and soft soil) the type of sharpening. In the presence of a muffle furnace, the edge is quenched.

- To clean the internal cavity of the projectile in the upper third, a longitudinal hole 3-4 cm wide is cut. The soil during impact-rope drilling dense clogs the projectile - it can be loosened with a crowbar and shaken out.

In the process of working with the bailer, you need to pay attention to the condition of the cutting edge - when that part splashes, other drilling methods must be used. This is due to the fact that large cobblestones are easier to select from the well with a screw tool. With a dense and viscous soil, it is better to fix a bell-shaped collar at the end of the chipper, with the extension down.

General recommendations and tips

A manual drill for home use is not difficult to manufacture, since the design of this device is simple. If we take into account the general design features of the drills, adjustment may become necessary in matters of hole diameter, drilling depth, the need for expansion below and soil features. Some craftsmen also recommend paying attention to a number of factors:

- When working on mixed soils, the teeth of the working part of the drill should not be sharpened.

- To work with clay soil, it is better to weld several teeth for loosening at the end.

- The soil crumbles less when working with a tool with a small clearance of the working part.

If you decide to purchase a drill in a specialized store, you need to pay attention to the strength of the metal. The handle should be comfortable, but with the possibility of extension, to increase rotational force. The diameter of the working part must be suitable for the intended use. The mass of the drill does not have to be large - it is easier to work with a light tool.

If the tool is intended for single use - it is better to rent it or order a job from professionals.

Conclusion

Automatic rigs for drilling wells are used for professional drilling, but for home use an expensive unit is not needed. For domestic use, a do-it-yourself drill is suitable. To do this, you need materials and rough drawings of devices of the necessary configuration - to fix the pillars or form a pile foundation.

Alas, no comments yet. Be the first!