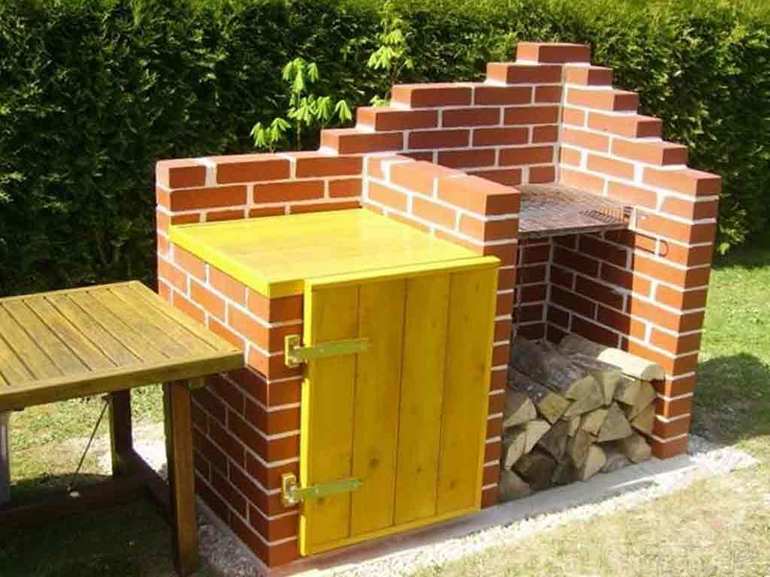

Building a furnace on the site is a snap even for those who do not understand its intricacies. If you build a barbecue out of brick with your own hands, it will save money and give pleasure to the owner and family members. And after construction is complete, friends will probably be photographed against the backdrop of a magnificent brick hearth.

Content

Barbecue Features

The lid of the heating surface is made of metal rings of different diameters, therefore, utensils of various sizes are used. A variety of dishes are prepared in the grill, baked fish, vegetables, and barbecue. A home-made structure is a center in which open fire is present, so the working surface is located at a height of about 80 cm. Raising the slab increases the risk of burns if you have to reach for distant products. A low furnace makes the owner bend, which is also inconvenient.

Quality food is obtained when laying the right fuel. More commonly used birch firewoodthat give dishes a delicate aroma. Similarly used apple tree, maple, alder, cherry, grape whips. The barbecue grill made of bricks is not melted by spruce and pine logs: they emit tarry substances that clog the firebox and chimney. Also, plywood trimmings, pressed chipboard sheets cannot be used.

Material selection

The outdoor barbecue in the country is built from refractory ceramic bricks, and the inner firebox must be made using fireclay bricks. The solution is prepared independently or mixtures are used for laying furnaces in a powder state. Dry solutions are purchased at points of sale. The walls are reinforced with iron wire, which is placed between the rows to increase strength.

For the preparation of concrete, quarry and river sand are taken, and the clay mixture for masonry is kneaded on the ravine form of the material. Sand is pre-washed from impurities with a water stream. The amount of sand in the mass depends on the clay content. When laying the initial rows, cement is added to the solution in the amount of 1 kg per bucket of the prepared mixture. Clay is pre-kneaded for 10-14 days to get wet, while being mixed daily.

The first rows are made of ceramic bricks without defects, cracks. The second grade of material, which is burned or not burned in the production process, is not suitable for a brick grill. With their own hands, a arch and arch are placed, which is made of blade brick or turned to the required shape of a standard material.

Construction of the country center

First, a place is determined on the garden plot for placing the barbecue. The furnace is not located near residential and farm buildings. The direction of the wind is provided so that the smoke does not interfere with the inhabitants of the country. The project of the future building is done on paper, taking into account all sizes. This drawing can be done by hand in the form of a sketch. Marking is required for accurate material counting and dimensions.

The step-by-step instruction for the construction includes the main stages:

- foundation construction;

- concrete waterproofing;

- barbecue masonry;

- installation of accessories;

- implementation of the arch with a jumper.

Foundation and waterproofing

Digging a pit, the size of which in width and length is greater than the dimensions of the brazier by 5 cm on each side. Soil is selected exactly according to the required values, so concrete is laid out in the pit. No need to do formwork.

The base device has its own characteristics:

- Crushed stone is placed at the bottom of the pit, which connects to the sand. The layer is rammed and spilled with water.

- Before adding water, the concrete components are mixed dry using a concrete mixer or manually.

- The surface after pouring is sprinkled with a layer of sawdust. In hot weather, it is poured with water to prevent cracking.

- The base gains 100% strength only after 28 days, but masonry is completed after 10 days.

Waterproofing is designed to prevent the transfer of moisture from the concrete base to the walls of the brickwork, which enters the foundation body from the soil. The insulation is carried out with 2 layers of building roofing or roofing felt, each of which is glued to resin or special mastic.

Brickwork and fittings

A sheet of felt or asbestos is placed on the hydroisol layer, which is wetted with liquid cement milk. Bricks of the first row are installed dry without mortar. The result of all the work depends on the correctness of the initial layer bookmark, therefore the drawing dimensions are clearly maintained, the horizontalness is checked, the order is established.

Two rows are carried out by continuous masonry, and from the third begins the formation of a place under the firebox, which is made with fireclay bricks. In the process, the protruding solution is removed inside and outside the masonry to maintain an attractive appearance and create a smooth surface in the furnace.

Blower doors and fireboxes are sold in the store or are cooked from metal yourself. Iron expands due to heat, so a gap is made between the box and the brick. Asbestos cord is used to fill the shrink gap or silicon based material.

Arched bridge

The arch not only performs a decorative function, but also distributes the load from the upper masonry. The arch is made in the form of a brick row, which is laid out in the form of an arch. First, a castle is placed (a brick in the center of the arc), then the remaining stones are collected.

The vault is laid using plywood or a metal template, which is fixed in the opening with spacers. The support is removed after the masonry has dried, and the protruding solution is repelled. Brazier can be covered with ceramic tiles to give attractiveness.

Alas, no comments yet. Be the first!