The need to install a supply valve on plastic windows is to ensure constant air circulation in the room. PVC products are inserted into the window opening. The material does not allow noise from the street and has low thermal conductivity. However, it does not provide ventilation. Thanks to the supply valve, the need for manual ventilation is eliminated, since the air masses come in automatically in the right amount.

Types of devices

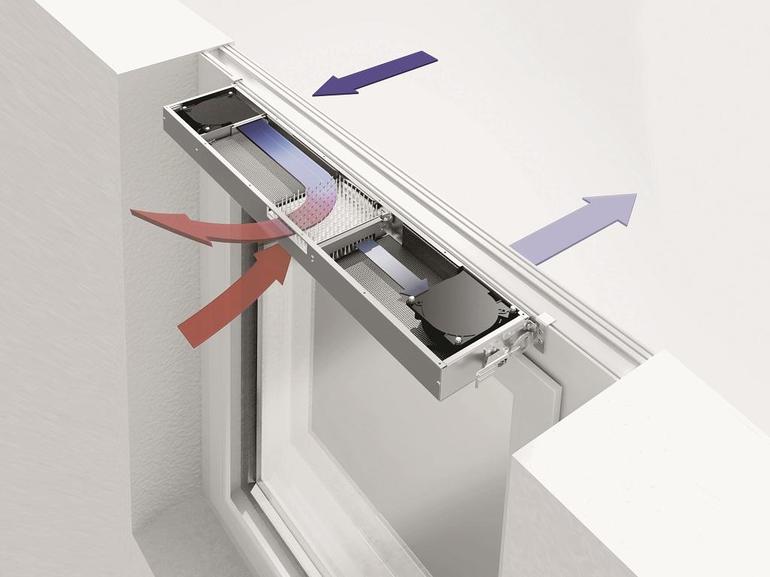

The differential pressure between the inside of the room and the outside provides ventilation in the plastic windows. The supply valve is the main component of this system. It is a gap through which air flows. The design consists of three components:

- air intake;

- channel for air passage;

- a filter;

- nozzles.

Depending on the device mechanism of the system differ in design. The ventilation valves for plastic windows come in the following varieties.

- Tame. Airing is carried out through the valve, which opens a little in the manual mode.

- Automatic. Equipped with a sensor that detects the degree of humidity of the air entering the room. A command is sent from him to reduce or increase the opening of the gap.

- Folded. Installation is carried out in the hole made in the sash or frame.

- Slotted. Consist of outdoor and indoor units. They have high bandwidth.

- A pen with a device inserted into it.

- Overhead.

Advantages and disadvantages

The air valve on plastic windows has several advantages and disadvantages.

Benefits include:

- when installing such a device in the apartment there are no drafts;

- there is a constant influx of fresh air, which stabilizes the humidity level in the room;

- simplicity in operation;

- lack of condensation on the windows.

Ventilation also has disadvantages.

They consist of the following points:

- in severe frosts, ice forms on them;

- inconvenient location - at the top of the window;

- not all varieties are equipped with filters, so dust may come from the street.

Installation process

To install the system yourself, you need to prepare tools and materials in advance.

These include:

- electric drill;

- file;

- jigsaw;

- screwdriver;

- sealant;

- supply valve with a set of components.

A template is being prepared in advance that facilitates the work.

Installation consists of several stages:

- A template is worn on top of the window. With it, the attachment points of the device are marked.

- A difficult operation is to drill holes in the sash, which are then connected to each other. A jigsaw is used for this purpose.

- The same operation is carried out on the influx of the frame, which overlaps the sash.

- The bar with the valve is attached. To do this, the inner part of the plank is treated with sealant, applied to the sash and fixed with screws.

- The same fastener secures a protective visor.

- At the last stage of installation, the sash and fittings are installed.

If the work is carried out by fixing the patch valve, the process is facilitated.

It consists of steps:

- A knife removes part of the seal on the sash and frame.

- The kit comes with a new seal, which is glued instead of the old.

- On the sash, in the place where the old seal is still left, are placed the caps included in the kit.

- The valve is fixed at the top of the sash using self-tapping screws.

The installation of forced ventilation cannot fully fulfill the function of an air conditioner. However, it is so able to refresh the air that there is no longer any need to ventilate the room with the help of window leaves or an open window.

The installation process itself is not difficult, and almost everyone can perform it.

Alas, no comments yet. Be the first!