It is not so easy to make a water heated floor with your own hands, but still this technology does not require special knowledge. You just need to understand some of the nuances. In rooms whose heating is performed in this way, it is much more comfortable to be located than where the radiator system was used. With this heating, the temperature in the room is distributed most optimally.

Content

Principle of operation

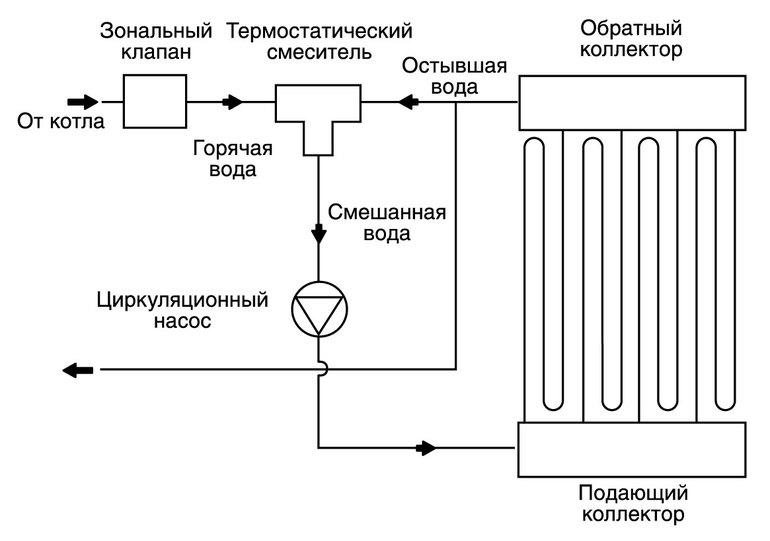

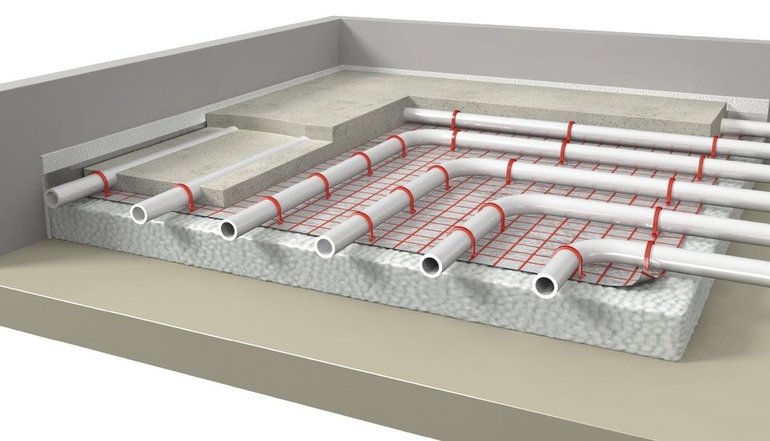

The device of a warm water floor is a stove. A heating circuit made in the form of a rubber pipe is installed in it. A thermal carrier circulates through it, heated by a heating element installed in the boiler.

The functioning of water floors is carried out according to this scheme:

- From the heating unit, a hot fluid flows through the wiring, which gives off most of the heat energy to the screed.

- Water temperature drops to about 30 degrees Celsius.

- The cooled coolant returns to the boiler through the return and is heated again.

Quite often, various sensors should be introduced into the circuit, which limit the amount of water in the circuit. This is done in order to control the heating power. For example, for floors covered with laminate, the temperature should not exceed 27 degrees.

Advantages and disadvantages

One of the main advantages of installing a warm floor is the uniform heating of the entire area. The heated air spreads vertically, so that the legs are always comfortable, and the head remains in relative coolness.

The greatest efficiency laying such a system shows in rooms with high ceilings. The air does not get excessively dry, and the whole apartment is heated evenly. Installation of a water heated floor is economically viable in the future, since it consumes less energy than radiators.

Pipe installation in bathrooms has its own difficulties. Most often they are associated with a heated towel rail, which leads to excessive floor heating.

Also, difficulties appear in apartments with low ceilings. This is due to the fact that the thickness of the screed must be substantial.

Pipe distribution

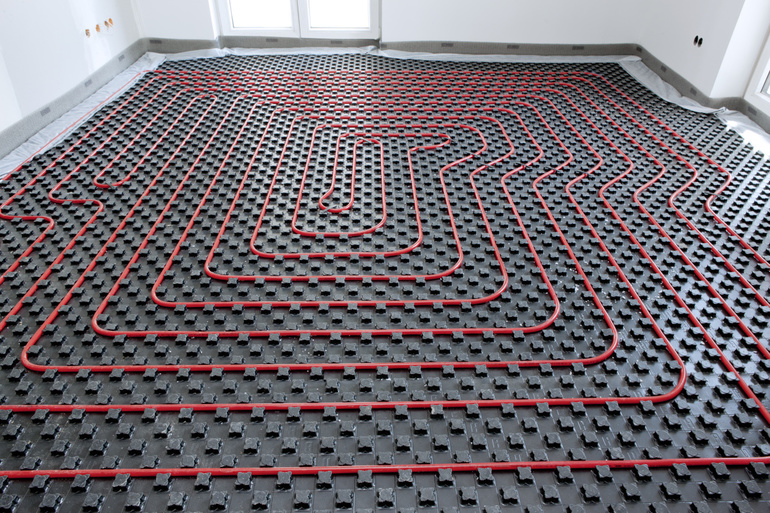

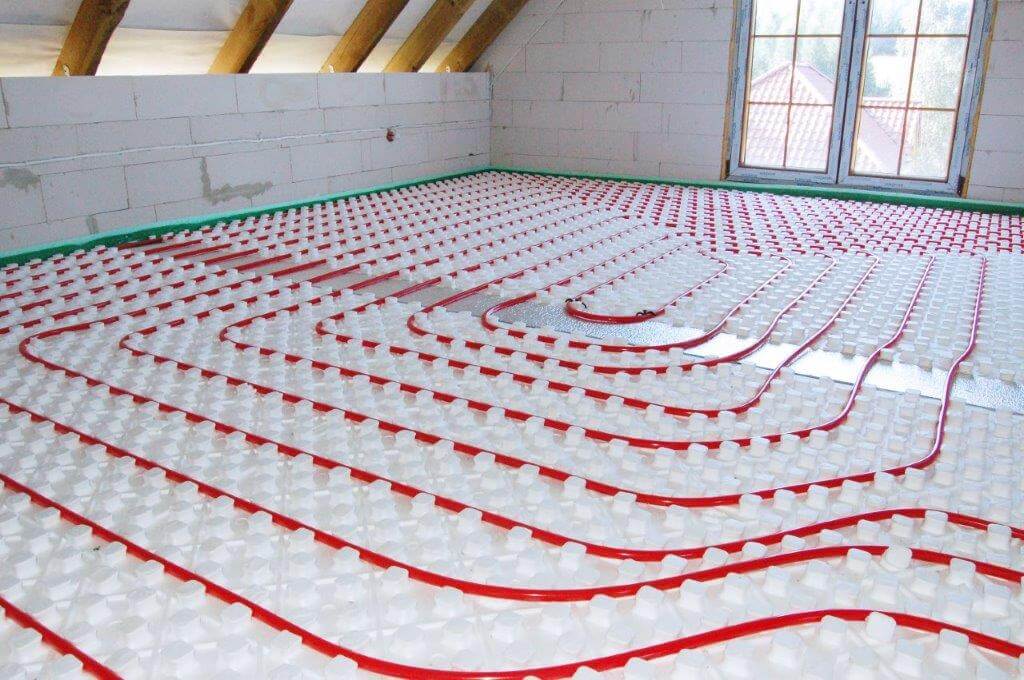

The cooling of the water passing through the pipes must be taken into account during the distribution of the circuit. It is necessary to correctly lay the laying route. When installing, you should remember some rules:

- It is always necessary to start the route from the coldest sections, for example, external walls, windows.

- It is necessary to lay "snake". So you can provide greater warming of the cold zones.

- In rooms with only internal walls, pipes lay in a spiral. Between turns it is necessary to double the distance.

- It is worth remembering the hydraulic resistance. It increases as the length of the pipe increases. Bends also affect. You should try to achieve approximately the same resistance.

- There should be no joints on the circuit. Couplings and other devices must not be used. This will significantly reduce the efficiency of the system and complicate its repair. Therefore, the purchase of materials must be completed only after the final settlement.

- Each room should have a separate circuit.

You also need to remember that cold rooms (verandas, balconies) should have their own line. Combining them in one circuit with living rooms is not worth it, since the heat transfer in different parts of the circuit will differ.

Installation and screed

For fixing and securing the contour, special fixing profiles are needed. They are screwed to the base of the floor with dowels. To perform this task you will need a hammer drill.

After this, the underfloor heating pipes are pressed to the screed net with plastic clamps. Tighten and pinch the pipe is not necessary.The loop must be made free.

During installation, you should be careful. It is impossible that the pipe breaks during bending. This is especially true for PVC material.

If a bright spot appears at a bend, then such a pipe no longer fits. Deformation has occurred, due to which an emergency situation may occur during operation.

After laying, the circuit must be brought to the collector. Before entering the floor, the pipe should be wrapped with thermal insulation, for example, foamed polyethylene.

The minimum screed thickness in living rooms and in the kitchen should be 10 cm. For bathrooms, this value increases to 15 cm.

Alas, no comments yet. Be the first!