Hot water in the apartment is a necessary condition for creating comfortable living conditions. However, in summer, public utilities cut off its supply for the time of preventive repair of boiler equipment, heating units or heating mains. In addition, there is a housing stock that is not connected to the centralized hot water supply system. This is the answer why a water heater is used to provide the house with hot coolant during the transition period. A rating of the best manufacturers will help you choose the right device.

Content

The main types of water heaters

The creation of an individual hot water supply system (DHW) begins with the selection of a heater. The type and capacity of the latter depend on the availability of energy resources. There are gas and electrical devices. The former need to be connected to a source of “blue fuel” and pose an increased danger due to the possibility of an explosion due to depressurization of pipelines. Electrical appliances operate on AC 220 or 380 V. Such heaters work quietly, are easy to maintain and repair, and are also safe to operate. Regardless of the source of energy, devices for heating water can be flowing, storage or combined.

Electric water heaters

In the private sector, among non-residential buildings in horticultural partnerships, in high-rise apartment buildings, it may not be possible to connect to the gas main. In this case, electricity is used to heat the water. Devices heat the liquid with the help of heating elements or induction elements. The first are a tubular electric heater located directly in the liquid. The induction element is placed outside the metal shell. The heating of the latter occurs due to eddy currents arising in the current-carrying part.

Electric storage heaters are called "boilers" (from the English boiler - boiler).

Flowing

Devices of this type are designed for instant heating of liquids. They are mainly used for one water-folding point. Flowing heaters are a steel vessel with a powerful heater. The liquid, flowing through the tank, is heated to the desired temperature, enters the mixer, where it is diluted with cold water. Advantage of flowing devices:

- Compact size. You can install the device under the sink or even on the mixer.

- Fast heating.

- Water heating if necessary. The inclusion in the work occurs when the tap is opened. When water does not flow, electricity is not consumed.

For fast heating, flowing devices must have a large power (from 3 to 27 kW). In an apartment with an internal electrical network of 220 V, a load of more than 8 kW cannot be used. However, such power is enough to heat 6 l in one minute to a temperature of 55 ° C. In a private house with a three-phase power system, you can install a more powerful heating device. Its performance is enough to create a complete DHW system. The disadvantages include:

- high power - in an old housing stock, the wiring may not withstand excessive loads;

- low productivity - with a strong drawdown, the device does not have time to heat the liquid;

- the possibility of overheating - if the device does not work properly, the protective mechanism will turn off the power to the heating element. To return to working condition, you need to drain cold water for some time.

Cumulative

Boilers are a steel thin-walled vessel with a heating element located in it. Hot water accumulates and is stored in the tank. To prevent heat loss through the walls of the vessel, they are covered with insulating material. Cold water enters the lower part of the boiler through a pressure pipe and is under constant pressure. The selection of hot liquid occurs at the top of the heater after opening the mixer. Due to the difference in density in the boiler, water is stratified. At the top is warm, at the bottom is cold. As the level of the latter increases, the thermostat turns on the heater for heating. The volume of the container is from 10 to 200 liters. Install boilers on the floor or hang on the wall.

There is a non-pressure type of boiler. It is used in the absence of a centralized water supply system: cold liquid is poured into the tank manually, when heated, it drains under its own weight.

When installing a hot water system in an apartment or a private house, it is important to choose the volume of the tank. The latter depends on the number of residents, the need for hot water, the number of points of analysis. On average, 50 liters per day are needed for one person. When choosing a heater, statistics are used:

- A boiler of 80 liters is enough for a family of three. This amount is enough to take a shower and wash the dishes.

- The volume of 100 liters is intended for four family members. Heated to the maximum water is enough to take a bath.

- Heaters with a capacity of more than 100 liters are used in private homes or large families. As a rule, they have a large capacity, and place them on the floor.

Heater volume - a parameter that affects the performance of the device and ease of use. When it is not enough, water is not enough for all needs. Excessive volume - excessive power and a long heating time. Boiler Advantages:

- Saving. On average, a heater for an apartment consumes 2-3 kW.

- Long service life. In the design of the device there are no moving parts that wear out quickly. The use of high-quality steels and protective coatings eliminates the corrosion of metal parts.

- Providing hot water to all points of analysis of the liquid. One boiler is enough to cover the needs of all residents.

Due to the design features, the boiler heats all the water at once. Therefore, after turning on the device, it needs time to raise the temperature to the desired level. The duration of heating depends on the volume and power of the device. Large dimensions of the water heater make it look for free space for its placement. Usually the device is hung in a bathroom or toilet. Some manufacturers produce models that can be placed in the cabinet under the sink.

Combined

The positive qualities of flowing and storage devices are combined in a separate device. Combined heaters have a small capacity (10-30 l) and low weight (no more than 6 kg). The flowing part works when the water in the tank heats up. After reaching the set temperature, the device switches to supply mode from the boiler. If warm water is not enough, the flow part is included in the work.

Gas water heaters

Owners of private houses and apartments connected to the gas main choose this energy source for heating water. The use of "blue fuel" is due to its availability, calorie content, price.Providing a home with heating and hot water is cheaper than using electricity. However, gas appliances have a more complex design. In addition, their operation is associated with the risk of the formation of an explosive mixture of fuel with air. This imposes restrictions on the use of heating appliances.

Gas water heaters are called "columns".

Cumulative

Capacitive devices heat water in advance. The advantage over boilers (in addition to the low energy price) is the ability to work in the absence of voltage. Ignition of the fuel is carried out automatically by a discharge from the piezoelectric element or manually by matches, igniter. Maintaining the desired temperature is carried out by electronics or a mechanical regulator. In this case, the combustion modes switch from small to large (with insufficient heating) and vice versa (when boiling).

The storage column consists of a metal tank with a volume of 50 to 300 liters. Heating occurs during the combustion of gas in the combustion chamber and the subsequent removal of combustion products. Distinguish between convective and radiation heat exchange zone. The latter is located in the combustion chamber at the bottom of the tank. Heat is transferred to the walls by means of radiation from burning gases. In this zone, the temperature reaches about 1200 ° C. Then, in the convective part, flue gases give off heat. The temperature of the latter at the outlet is in the range from 120 to 200 ° C (depending on the intensity of heating). A convective heat exchanger is placed along the axis of the tank for additional heating of the water.

Flowing

The flow-through column is a heating structure with a heat exchanger. The latter is placed above the combustion chamber in a protective casing. Heat from the combustion of gas is transferred to water through the walls of the heat exchanger. Ignition of the fuel is carried out with a pilot light when opening a hot water tap. Geysers have a number of locks to prevent failures or a possible explosion of the combustible mixture:

- control of the movement (flow) of the fluid through the heat exchanger;

- check for flame on the igniter and burner;

- monitoring the water pressure at the inlet to the column;

- protection against overheating (boiling).

Column installation is coordinated in the gas service and water utility. When installing, you must observe several rules:

- In the room where the device will be located, a chimney and exhaust ventilation are organized.

- Area - at least 7.5 m2, ceiling height - from 2 m.

- The wall at the mounting location must be made of non-combustible materials.

- The distance from the column to the stove is at least 0.5 m.

Due to the high temperature in the combustion chamber, the latter is placed in a liquid for good cooling and is made of heat-resistant steel.

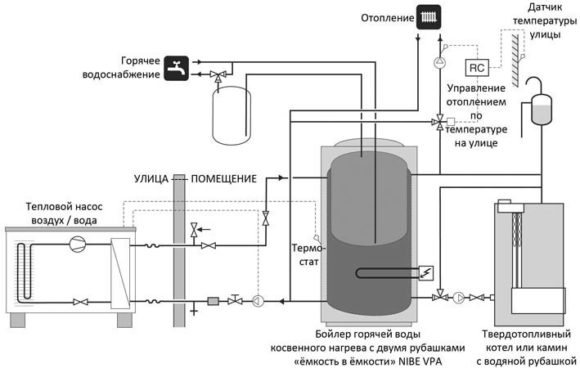

Indirect Water Heaters

An indirect heating boiler uses a heat carrier from a heating system or other source as an energy source. The principle of operation is to separate the contours of the fluid. The heating system has a closed chain in which purified (softened) water circulates. The latter is a heat source for heating. And also it heats the DHW system. The high temperature of the water in the indirect heating device is maintained by the circulation of the hot heat carrier.

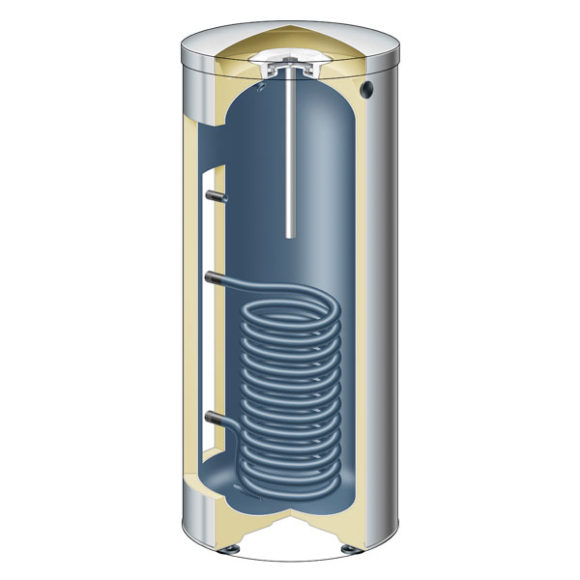

The water heater consists of a metal tank with a capacity of 10 l to several thousand and an integrated heat exchanger. The latter is connected to the heating system together with a thermostat to adjust the heating temperature. The tank is made of stainless steel or coated from the inside with anticorrosive materials. Outside, the container is covered with several layers of thermal insulation and a decorative case made of plastic or thin metal. Depending on the installation option, the heater has one or two pumps for circulating the coolant and heated water.

The advantage of an indirect water heater, in comparison with an electric or gas one, is the use of a heated coolant.However, such designs have large dimensions and weight. This is necessary to increase the contact area between the heating fluid and cold water. Other advantages of indirect heating:

- No connection to the electrical network or gas main.

- Low maintenance.

- Use of third-party heat sources.

- No need for clearance permits.

- Operational safety.

Type of heating element

Convert electrical energy into heat tubular or spiral heating elements. The working element in them is a thin metal wire twisted into a spiral, made of an alloy of nickel with chrome. To protect against contact with water and mechanical damage, the heating element is placed in a metal tube, filled with ceramic filler. Additionally, a temperature regulator and a magnesium anode are placed in the heating elements. The latter is needed to prevent internal corrosion of metal parts, as well as to prevent the formation of scale.

"Wet" TEN

A tubular heating element is conventionally considered “wet” because it is completely immersed in water. Due to this, the conversion of electric current to heat occurs with maximum efficiency. However, direct contact with water leads to the formation of scale on the surface of the heating element and intense corrosion of the metal shell. The appearance of dense deposits of sludge affects the heat transfer between the heating element and the liquid. As a result, the TENA shell is destroyed. The disadvantages of the "wet" heating element:

- When replacing, completely drain the water from the boiler.

- The destruction of the metal shell leads to electrical breakdown, which increases the risk of electric shock.

Simplicity of design and low price are the reasons for the mass use of tubular electric heaters. However, this also reduces the life of the element.

"Dry" heating element

The disadvantages of the “wet” heating element were eliminated in the new design. For this, an open heating element was placed in a ceramic case. A “dry” heater is inserted into a metal flask, which is welded to the boiler shell. This made it possible to exclude contact of water with the surface of the heater. However, the efficiency of the system decreased by 5-7% due to a decrease in heat transfer - the “dry” heater became much more heated.

The cause of overheating is the deposition of a large amount of scale on the walls of the flask. As a rule, there are two “dry” elements in the boiler. If one burns out, the second will allow the heater to be operated until the scheduled repair. Electrical breakdown is possible if the bulb is damaged. In this case, the liquid enters the heating coil, which is energized. It is also possible for hot water to leak out of the housing. To prevent breakage, you need to monitor the quality of cold water and timely change the magnesium anode.

Boiler inner cover

Aggressive aqueous medium, under the influence of high temperature, intensively oxidizes the surface of the metal. In storage heaters, the coating of the inner walls performs the function of protecting the housing material from corrosion. The use of inert materials resistant to the effects of the aquatic environment allowed several times to increase the life of the boiler. The internal cavity of the tank is covered with enamel, glass ceramics, titanium spraying.

Stainless steel

The stainless steel case does not require additional materials. Alloyed with a high chromium content, the metal is not susceptible to corrosion, but its price is several times higher than ordinary metal. Steel for its characteristics has spread in the post-Soviet space. In the West, they refused to use highly alloyed material in the production of heating tanks due to the complexity of the assembly process. Only a few Scandinavian firms produce stainless steel boilers.The steel used in their construction meets the most stringent sanitary standards, and the functionality meets any request.

During the intense flow of hot water, stainless steel is not susceptible to cracking and deformation during sudden changes in temperature. In addition, the absence of brittle materials in the lining makes the heater shockproof. The main disadvantage is corrosion of welds. The metal of the latter is oxidized in the aquatic environment. As the material is thinning, fistulas or partial damage to the main body may appear at the joints.

The magnesium anode in stainless steel housings is placed during assembly. You can replace it only by cutting the shell.

Glass porcelain

Steel tanks with a protective coating - a large class of water heaters. Initially, an ordinary enamel was applied to the inner surface, similar to that of steel bathtubs. But during operation, the coating cracked and peeled off. Upon contact of steel with water, the first began to intensely corrode. The service life of such devices was 3-4 years. At the end of the working period, the heater body could not be restored.

Damage analysis showed that for the durability of the coating, it is necessary to select the coefficient of thermal expansion of the protective coating similar to the metal of the vessel. Glass porcelain corresponds to the required characteristics. It tolerates large fluctuations in temperature, has high hardness and elasticity. In addition, water does not interact with glass porcelain, remains clean and fresh for a long time, and scale does not form on the walls of the vessel.

The coating is applied in two ways: “dry” and “wet”. The first option is to spray a glass-ceramic protective layer using electrostatic deposition. Fine powder is sprayed inside the tank, a negative potential is applied to the body, and charged particles of the material are attracted to the metal surface. The thickness of the protective layer is several micrometers.

The second method is more economical, it is used to produce inexpensive models of heaters. A glass-ceramic coating is formed by spraying an emulsion. When applied, it flows down the walls, forming thin sections in the upper part or tearing of the film. Defective places during operation do not protect the metal surface well. In addition, corrosion in the upper part of the boiler proceeds more intensively due to the formation of an air gap there.

Titanium coating

The protective layer is applied only by electrochemical spraying. Titanium forms a thin, inert film on the surface, which is resistant to high temperatures and aggressive environments. However, due to the high cost of the protective material and the complexity of applying the model with such a coating are not widely used among users. In addition, it has weaknesses - welds. Most often, corrosion manifests itself there, and water heaters with this type of tank are several times larger than enameled ones.

Boiler tank shape

The most common cylindrical apparatus. Round shells are easier to make, they withstand greater water pressure with a smaller wall thickness. Thanks to this, the boilers are compact and lightweight. However, they have two drawbacks:

- Round water heaters take up a lot of space.

- It can be very difficult to integrate them into the interior of a kitchen or bathroom.

Cylindrical models can be hung on the wall or mounted on the floor.

Boilers with a rectangular body look neat, they can be placed in a small niche or behind decorative panels. However, the high load on flat walls limits the volume of the apparatus to 0.15 m3. For mounting the heater near wooden structures or furniture, its walls are covered with insulating material.The heater maintains a high temperature of the water even after a power outage.

Vertical and horizontal water heaters

The most common heating devices are vertical models. The supply of cold water in them is made in the lower part of the housing. When heated, its density decreases, and the hot liquid rises. This is the formation of layers with different water temperatures. The outlet of the heated fluid is located at the top of the boiler. The physical process of temperature distribution eliminates the addition of cold water to hot.

Horizontal units save space, they can be fixed so that they do not interfere in the bathroom or kitchen. This arrangement of the heating device gives the user certain benefits:

- Small boilers are usually used in kitchens. They are small in size, and therefore do not take up much space and do not create any problems for residents. They can be hidden in the kitchen.

- Larger models after installation on the wall are covered with decorative panels.

Boiler control system

The temperature of the hot water in the storage water heater is maintained by a mechanical or electronic thermostat. The regulator turns off the heating elements when the liquid warms up to the set value. The mechanical thermostat has a movable copper rod, which lengthens or shortens when the temperature changes. The movement of the sensing element is perceived by the contact group, which commutes the connection of the heater to the mains. The mechanical regulator has a simple design and high reliability.

The electronic controller is arranged somewhat differently. It contains the measurement of temperature, comparing it with the set values and issuing a control signal to the switching device. The mechanism is noteworthy in that the user can set any value from 0 to 100 ° C. In addition, the digital display shows the current water temperature in the boiler.

The electronic controller has an option to save energy. On specified days or hours, the automation will reduce the temperature of the water in the drive, reducing energy consumption.

Additional functions, equipment, installation

Together with the main equipment, the boilers supply an additional set of fittings and fittings for mounting the device and connecting it to the water supply network. The number of components depends on the manufacturer and model of the heater. Typically, parts are purchased separately. To connect to the water supply you need:

- shutoff valves (ball valve or valve);

- safety valve;

- strainer;

- hoses;

- residual current device (RCD).

Shutoff valves are installed on the cold water pipeline to turn off the device in emergency situations or for repair. Then the remaining consumers will be connected to the highway. After the crane install a safety valve. It is necessary to relieve excess pressure. The latter is formed in a closed container when heating cold water and its temperature expansion. If there is no valve, or it does not work, excessive pressure can destroy the boiler body. RCD is necessary to protect the user from electric shock. Danger arises from damage to the heating element. When there is even a slight leakage current, the protective device will instantly de-energize the device.

Rating of manufacturers of electric water heaters

Recently, electric boilers are gaining popularity. The reason is the deterioration of the utilities system or the complete absence of a centralized hot water supply. The owners of the heater are independent of external factors: hot water of a given temperature flows from the tap at any time. A huge number of heaters of various shapes and designs. A brief overview of popular electrical appliances will help you choose a manufacturer and model.

The design of the DHW system begins with determining the characteristics of the water heater. Popular models are listed below.

Table.Rating of manufacturers of water heaters

| Category | A place | Title | Rating | Average price, rub. |

| Budget segment | 1 | Ariston | 9,8/10 | 8300 |

| 2 | Thermex | 9,6/10 | 5800 | |

| Middle niche | 1 | Gorenje | 9,9/10 | 13700 |

| 2 | Timberk | 9,7/10 | 6700 | |

| 3 | Electrolux | 9,7/10 | 14100 | |

| Premium models | 1 | Stiebel eltron | 9,9/10 | 13200 |

| 2 | Aeg | 9,8/10 | 23500 |

The boiler market is crowded with models with different characteristics. A beginner can get confused and buy an unreliable water heater, which will last 1-2 years at best. To avoid this, it is necessary to take into account the design consumption of hot water, the availability of energy resources, and the rating of manufacturers.

Alas, no comments yet. Be the first!