The ceiling takes up to 40% of the heat transfer of the structure. Its insulation is a sore subject for many families. To make the ceiling insulation in a house with a cold roof, you need some knowledge and skills. This process is not always easy to carry out and it has features. But, modern materials facilitate insulation work for a ceiling with a cold roof, thanks to this, a novice builder can also manipulate.

Content

The difference between warm and cold roofs

A properly equipped roof is a system that includes a list of steam and waterproofing measures, protection from wind, snow load, noise, cold and other natural factors. The roof should play out not only a functional role, but also have a pleasant appearance. When there is a violation in the arrangement of the roofing cake, condensation accumulates under the coating, which provokes corrosion of the metal, wear of the wooden components and the waterlogging of the insulation.

An insulated roof is an additional useful space that is used for living quarters. For such attic floors, semi-hip roofs are often used. But, some owners prefer to build standard two- and four-slope constructions. The base of a thermally insulated roof is an eight-layer roofing cake, which consists of such elements:

- roofing material - tiles, slate, ondulin;

- crate;

- counter lath;

- waterproofing layer;

- truss farm;

- thermal insulation;

- interior decoration.

The key difference between a thermally insulated roof and a cold one is in the presence of heat-insulating materials that do not allow heat to escape from the attic floor. The reliability and quality of the roof does not depend on the coating used, but on the materials from which the layers of the roofing cake are made. The insulated roof has many advantages, but the 2 main disadvantages can block them - a longer construction period and the need to purchase an increased number of building materials.

Layers of insulation, coatings, finishes, hydro, wind protection, vapor barrier - this is a roofing pie.

The cold roof is chosen when the attic is used to store things. The uninsulated design is suitable for household buildings. The main thing is to make good waterproofing, which will increase the life span of the roof. But, the roof without thermal insulation is sometimes converted into insulated. The choice of an insulated design has a number of positive aspects, which are hidden in the following:

- ease of installation;

- low price;

- construction speed;

- reduced material consumption.

Cold roofs have more significant negative sides, which are enclosed in additional expenses when heating a house. In addition, such structures are characterized by low soundproofing parameters and an increased risk of deformation at sub-zero temperatures. A roof without insulation is built quickly, but without insulation, you can live in such a house with comfort only in the summer.

Thermal insulation of the area under the roof

The issue of thermal insulation must be addressed at the design stage of the house.But, this is permissible to perform after construction - when the house is old and thermal insulation was not originally provided. If the building is built with the expectation of permanent residence, then you must immediately take into account the thermal insulation of the roof. When they make the ceiling insulation in a house with a cold roof, which is especially true for buildings made of wood, they get a number of advantages:

- The insulation enhances sound insulation, which reduces the amount of noise from the street during bad weather.

- In the summer season, insulation material reduces the amount of heated air entering the house from the street. This facilitates climate control.

- In the winter, insulation reduces the amount of "lost" heat and reduces the cost of heating.

You can perform insulation work yourself or hire builders. But, when deciding to do it yourself, you need to carefully look at all the teaching materials that describe the process of roof insulation. In addition to studying the techniques of the insulation procedure, you need to carefully approach the selection of building materials, which determine the ease of work and the degree of final thermal insulation.

Insulation fasteners are performed in two ways - from the side of the lower floor or from the attic area. The right tactic is the fastening of insulating materials on the attic side. In most cases, the ceiling is constructed of wood, which also has good thermal insulation properties and therefore it is not necessary to additionally insulate it. After the end of the insulation fasteners, the surface of the subfloor is formed on the floors of the attic. During the insulation, which is done on the attic side, roll and fill materials can be used - unlike heat-insulating work from the living space.

The insulation made according to the standards will reduce the cost of heating the house by almost 30% due to the reduction of heat loss.

Types of insulation

Heat costs are reduced with the quality of thermal insulation measures in a house with a cold roof. This procedure increases the comfort of life in such a structure and allows you to more judiciously use the available space under the roof. Thermal insulation can be done using different materials that differ in characteristics and ease of mounting.

In fact, in all residential buildings of a private nature, gas or electric heat-generating equipment is installed. These devices are installed even in those houses that are used as housing only seasonally. In such houses, the roof is almost always cold. Thermal insulation of the ceiling in a residential building is done when they decide to spend time in the house, not only during the warm season. This allows you to comfortably be in housing and in the cold.

Criterias of choice

In the construction market there are many materials with thermal insulation properties that can be used for warming cold roofs in residential buildings. In order to choose a good option, it is necessary to analyze the heaters that are on sale for compliance with the standard list of requirements. The key criteria when choosing thermal insulation materials are as follows:

- Thermal conductivity - heaters with the lowest this coefficient are recognized as the best.

- Durability - how insulating is susceptible to temperature extremes and whether it can withstand prolonged exposure to moisture.

- Environmental friendliness - the insulation must not pose a health hazard and do not vaporize harmful compounds.

- Moisture resistance is a significant parameter in the case of cold roofs, which were built a long time ago and have already partially worn out.

- Flammability - insulation for a cold roof must be either non-combustible or slightly combustible.

Sawdust, expanded clay, basalt cotton wool are the demanded types of thermal insulation materials for warming residential buildings in the private sector with a cold roofing pie.Expanded polystyrene, slag, polystyrene, ecowool, polyurethane foam, clay, hay and algae are also used. The insulation is laid on the side of the attic, filling the voids of the floor, or the materials are laid directly on it. The technology depends on the option chosen and the type of overlap.

For wooden floors, lightweight insulation should be used. Dense heat-insulating materials in the form of mats or slabs and heavy backfill can only be used when the floor is concrete.

Expanded clay

Lightweight, non-combustible, bulk material based on clay. This insulation is environmentally friendly, has absolute moisture resistance and sufficiently high thermal insulation parameters. Expanded clay - a material in which rodents or pests do not start. This insulation is used often, it has many positive aspects. The main advantages of using expanded clay are as follows:

- low price;

- availability;

- thermal insulation characteristics are above average.

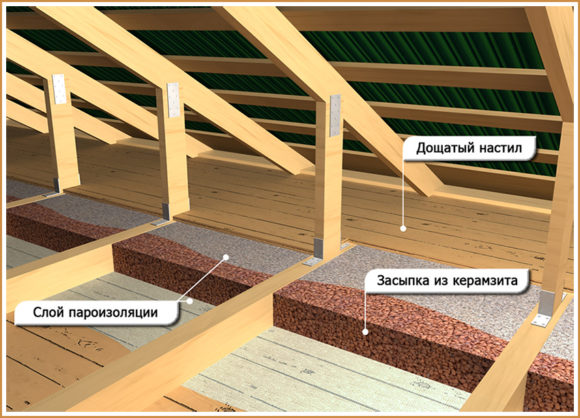

But, the use of expanded clay has a list of restrictions, the main of which is contained in the mass of insulation. To use such thermal insulation, it is better that the floors are made of concrete. For expanded clay, it is advisable to do additional vapor barrier. Expanded clay should be laid in a thick layer - at least 20 cm.In order to retain heat in large volumes or in the case of a harsh climate in the region, the expanded clay layer is brought to a thickness of 50 cm. Using this option of insulation, specialists mix small and large fractions to increase the percentage of filling voids. Cement mortar is poured over the expanded clay layer, the thickness of the screed is 5-10 cm.

Ecowool

Ecowool is a safe insulation that does not evaporate harmful compounds. This material is made on the basis of cellulose and it is characterized by decent thermal insulation properties. Ecowool is a modern insulation for residential buildings, it contains flame retardants that guarantee fire resistance, and boric acid prevents the development of fungal and pathogenic microorganisms. The main positive aspects of ecowool are in the moments:

- Closing the entire space of the attic, and thanks to the small mass of individual parts, it is easy to blow ecowool into small cracks.

- High thermal insulation characteristics can reduce the consumption of insulation, which is needed.

- Ecowool is a lightweight insulation that can be used in the case of wooden floors.

But, there are also disadvantages of ecowool - it does not tolerate moisture well; it’s impossible to put quality insulation without special tools. This material is also subject to shrinkage (a margin of 15% is needed), and when compressed it loses its insulating properties. Due to the last parameter, it is necessary to lay boards on top of the heat-insulating layer of ecowool that will allow you to move around the attic space.

Flame retardants have been added to ecowool, but they are not recommended to use such insulation near chimneys and other heat sources. If laying is done in the immediate vicinity of heat sources, an additional fire-resistant fence must be equipped.

Mineral wool

Minerals have all the necessary characteristics that meet the criteria for determining high-quality thermal insulation materials. Minerals based on mineral wool are characterized by low flammability, a reduced coefficient of thermal conductivity and decent indicators of soundproof and vapor-proof properties. Mineral wool actually does not absorb moisture, has resistance to mechanical stress and a long period of operation - up to 50 years. Insulating a cold roof with mineral wool has a number of positive aspects:

- insulation is cheap;

- masonry speed is high;

- thermal insulation parameters are high.

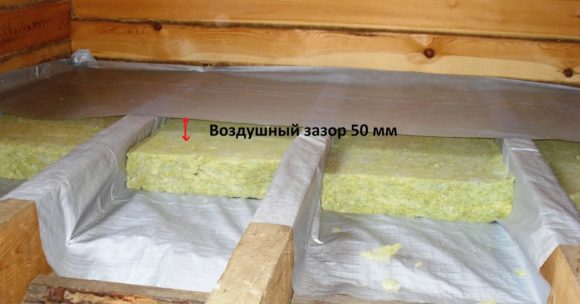

But, mineral wool has drawbacks, the main of which is the degree of shrinkage - 15-20%. Because of this, it is necessary to lay the insulation with a margin.It is recommended to equip an additional layer of waterproofing, which will reduce the thermal conductivity of mineral wool. In addition, crushing mineral wool is undesirable, since the degree of thermal insulation properties is directly dependent on the air present between the fibers. Because of this, it is necessary to lay the floor covering, which will not put pressure on the insulation. It is necessary to put wooden logs that delimit sectors and are a support for the future floor.

Penoizol

Depending on the installation technique, penoizol is poured or sprayed. But, this insulation can only be used with specialized equipment and in protective suits. In addition to protective clothing and construction equipment, the use of penoizol requires certain skills. Nevertheless, the insulating material has a fairly impressive list of positive aspects, the main of which are:

- Ease of filling all cracks with penoizol, including microcracks.

- The complete lack of combustibility allows the use of insulation near chimneys and other sources of high temperatures.

- After solidification, the insulating material is harmless to health.

- Rodents do not start in the penoizol layer.

- The construction composition contains a large content of air bubbles, which guarantee reduced thermal conductivity.

The use of penoizol also has negative aspects. The two key disadvantages are the fragility of the insulating material and its high price. This insulation after mechanical damage is not able to restore its original shape on its own and loses most of its insulating properties. Because of this, in the attic you need to equip a protective floor covering.

Expanded polystyrene

Expanded polystyrene is a relative novelty in the construction market. But, this is the main competitor of traditional materials for insulation, which is made on the basis of extruded polystyrene foam. The positive aspects of such a heat-insulating agent are the reduced coefficient of thermal conductivity, low weight and relatively low price.

But, polystyrene foam also has negative qualities and the main drawback is a small vapor permeability, which forces us to pay more attention to ventilation. In addition, insulation is difficult to use when it is necessary to perform thermal insulation of ceiling structures of complex configurations. But, for flat structures, extruded polystyrene foam is a good option, since its mechanical strength is quite high.

Isospan

This material has the ability to prevent corrosion of metals, and in the case of wooden structures - rot. Isospan prevents the passage of air currents and does not allow heat to go outside. When selecting isospan, one must take into account the quality of modifications that have certain features. Isospan has many advantages, the key of which are:

- Strength - during fastening, the isospan does not break, and the service life is high.

- Reliability - during laying of a heater other materials keep dry.

- Versatility - you can use a heat-insulating agent on any structure.

- Environmental safety - does not emit substances harmful to health in the air.

- Refractoriness, practicality and convenience of fixture.

But, isospan has its negative sides - wooden structures must be treated with antiseptic solutions. In case of deviations from the fastener technology, condensation may occur at the joints. You can not use isospan rolls immediately - they need to acquire the temperature of the room. During fog or other precipitation it is forbidden to fix the insulation.

Isospan evaporates condensate well, which enhances its thermal insulation characteristics.

Penoplex

This insulation has many positive properties.The main advantage of penoplex is a small percentage of moisture absorption, which is 0.4-0.5% of the volume for 1 month. Thermal conductivity is lower in comparison with the characteristics of mineral wool, but it is always the same and does not change when the plates get wet. In addition to the described, penoplex has such advantages:

- The long period of operation is 50 years or more. This was established during the frost resistance tests of the insulation. At the end of multiple freezing and thawing cycles, the characteristics of the foam remain the same.

- The uniformity of the structure of the extruded polystyrene foam, which consists of uniformly distributed cells and increases the resistance of the insulation to mechanical stress.

- Penoplex does not have zero chemical activity, but most of the building compounds do not react with these heat-insulating plates. It is only necessary to prevent the contact of this insulation with gasoline, epoxy hardeners, formalin, acetone, kerosene, oil painting compounds.

- Foam foam has high frost resistance, but high temperatures are harmful to plates - under the influence of heat they lose their original shape and structure. But, flammability is minimal.

Plates of foam are not subject to decay. The environmental friendliness of the insulating material, subject to the technology of its production, is in order. Insulation plates are safe for health and do not emit harmful fumes. Penoplex is a universal thermal insulation tool that can be used not only for warming cold roofs of private houses.

Polyurethane foam

The use of polyurethane foam as a heat-insulating agent avoids the use of additional waterproofing agents, primers, fasteners. This reduces the cost of warming the cold roof. Polyurethane foam, as a heat-insulating agent, has a certain list of positive aspects, which are as follows:

- good performance;

- resistance to mechanical damage;

- moisture resistance;

- high sealing characteristics;

- ease of processing after hardening.

Polyurethane foam spraying is an expensive type of thermal insulation. Basically, this composition is used not in private construction, but for the insulation of hangars, garages, warehouses and other office premises.

Polyurethane foam is the basis of polyurethane foam, this substance has a high price, so it is better to trust the warming process to specialists. The application of the polyurethane layer is performed by operators in protective suits using specialized equipment for spraying the thermal insulation composition. For the correct distribution of the insulating substance, certain skills are needed.

Basalt wool

Such insulating material is made of solid basaltic rocks. The insulation has high strength, moisture resistance and ductility. Mats are made from basalt cotton wool or sold in foil rolls, which increases the thermal insulation characteristics. Basalt cotton wool can be used without restrictions if it is necessary to insulate the enclosed space. This insulation is the best type of thermal insulation building wool for a private house.

But, basalt wool has a significant drawback - phenol-formaldehyde resins in the composition. These substances decompose over time and are released into the air in the form of unhealthy compounds, which are classified as carcinogens. When fastening basalt wool in rolls, the foil side should be on the bottom. Mats are easy to lay, but safety precautions must be kept in mind. Cut the roll on a hard surface. The best thermal insulation characteristics of basalt wool are preserved if the material was not wrinkled during installation.

Slaggy

This material is another representative of building heat-insulating watts, which are used for warming structures for various purposes. The main attractive point for owners of private houses who need to perform cold roof insulation is the low price of this material. But, it is not recommended to use slag in private construction of residential premises.

Slag wool is a heat-insulating agent that is made from metallurgical waste. The main “ingredient” of the insulation is blast furnace slag. This material absorbs moisture well, and then begins to evaporate acid, which negatively affects other structural components, especially metal parts.

Acid, which is secreted by slag after wetting, corrodes metals and leads to an accelerated flow of corrosion.

Styrofoam

Polyfoam as a heat-insulating material in private construction has many positive aspects - low weight, a large selection of plates of different thicknesses. The insulation is easy to fix and easy to handle with construction tools. Polyfoam has high resistance to temperature shocks and certain types of mechanical stress. This thermal insulation material also has the following properties:

- long service life;

- preservation of shape and properties when in a humid environment;

- low price;

- environmental friendliness;

- hypoallergenicity;

- Fire safety.

But, the foam also has significant drawbacks - when exposed to open flame, the material releases harmful compounds. A small amount of moisture can accumulate in foam slabs, which leads to the development of fungi, mold on the crate, rafters and finishing materials. Foam plates cannot completely cover the gap between the rafters due to stiffness, which reduces the quality of thermal insulation. Rodents can live in the insulation and it is actually airtight. Polyfoam reacts poorly to alcohols, solvents, refined products and sunlight.

Natural heaters

In addition to thermal insulation materials, which are made on the basis of natural and artificial substances, other means are also used to warm the cold roofs of private houses. Materials of natural origin are quite popular as a means of thermal insulation, since their price is low, and thermal insulation works with their participation are simple. The main options for natural insulation are:

- clay;

- sawdust;

- dry leaf litter, grass;

- seaweed;

- straw;

- needles;

- hay;

- reeds;

- moss.

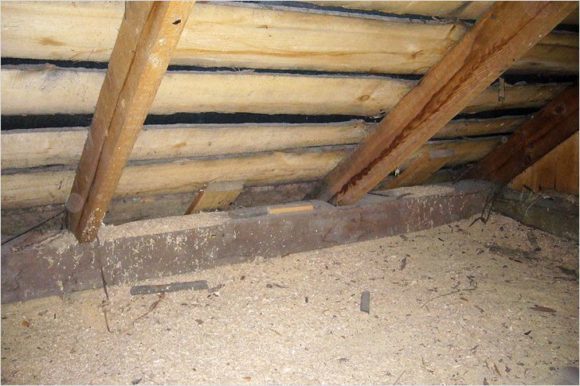

Sawdust, reeds and more have been used for several hundred years. Thermal insulation using natural means is recognized as a good and cheap material. Sawdust can be bought at any enterprise that is associated with the woodworking industry, other materials can be collected independently. The main negative point is that these materials absorb moisture and are very combustible.

Any natural insulation is susceptible to decay, so the life of such materials without treatment with special compounds is up to 5 years.

Sawdust

The cheapest thermal insulation material among all bulk heaters. The total cost of thermal insulation work using sawdust is the lowest among all materials. But, the quality of wood chips or sawdust for use as a heat-insulating material has a number of requirements. If the raw materials do not correspond to them, it is impossible to insulate the roof with sawdust or shavings. The main criteria for determining the permissible use of sawdust are as follows:

- The minimum moisture content of the raw material, in another case, mold fungi will rapidly develop. Sawdust for insulation must lie in a dry room for 1 year.

- To reduce flammability, it is necessary to treat wood chips with flame retardants.

- It is necessary to mix sawdust with fungicides, antiseptics and slaked lime - to protect the material from rodents, fungi, mold.

The cold roof is insulated using sawdust in two ways. In the first embodiment, the natural insulating material is mixed with dry cement and then some water is added. Cement is a bonding component that does not allow sawdust to crumble. The second way - dry falling asleep sawdust without a binder component. But, sawdust has a high degree of shrinkage and their volume must be regularly supplemented with new portions.

Clay

It is a material with high thermal insulation properties. The only drawback of the insulation is the mass. Because of this, various lightweight versions of the material are often used. Straw or sawdust is added to the liquid clay solution. The proportion is determined so that the solution does not lose plasticity and easily penetrates into cracks and cracks. The positive side of clay - its prevalence and this material does not need additional processing - just dilute with water.

More often clay is bred in a construction container with a wide opening, from which it is convenient to get the mixture and distribute it over the insulated area. After solidification, the cracks that have appeared are re-treated with a liquid clay solution with the addition of sand. The clay layer is determined on the basis of climatic conditions, usually it is performed with a thickness of 15-30 cm.

The main advantage of clay as a heater is fire safety.

Straw and hay

These natural thermal insulation materials are now practically not used for warming cold roofs. This is a consequence of the high flammability of straw and hay. But, when combined with a liquid clay mortar, pressed straw loses combustibility almost completely. In some cases, straw is the most affordable insulation, for example, when there is an enterprise in the district that cultivates rye or wheat. Rye is preferred.

You can buy pressed straw in bales of the desired parameters. Laying heat-insulating material in place does not take a lot of time and does not involve the use of specialized tools. The heat-saving effect of hay and straw is quite high. A layer sufficient for good insulation is 25-30 cm. Before laying it is recommended to process the material with flame retardants.

Seaweed and reeds

Each year, many tons of algae are thrown ashore by the sea. Residents of coastal areas often use this material as insulation. Mainly used for thermal insulation cam - branched durable long algae. Dried and collected in an armful of algae evenly cover the insulated space. This material can be used for thermal insulation even in an under-dried form. Algae are not susceptible to mold, do not respond to humidity changes and rodents do not start in them. In this case, the material releases accumulated iodine, which purifies the air of bacteria.

Reeds are near many bodies of water. But, the procurement of this material is a painstaking task. To use reeds as thermal insulation, it is tied into mats using metal wire. These ligaments are placed between the lags in several layers so that the seams and crevices are filled as much as possible. Like algae, rodents do not start in reed insulation, it is resistant to moisture and does not rot.

The ignition temperature of reed mats is much higher than that of wood sawdust.

Dry foliage, grass and moss

These materials are rarely used now - this method of insulation is considered exotic. But, dry foliage, grass and live moss are often used to warm houses in rural areas. In addition, these materials are common for thermal insulation of forest cordons and hunting houses. The best thermal insulation properties are characterized by the leaves of such tree species:

- coniferous;

- oak;

- hornbeam.

When lining moss as a heater, they prefer to use reindeer moss. Any grass is suitable. The main condition for the use of this natural heat-insulating material is dryness and shelter, the performance of a coating of non-combustible materials - slag or clay. Grass and foliage are gradually compacted into a solid mass, which is virtually completely fireproof. The initial thickness of the embankment is 20 cm.

Features of insulation from the lower floor

Work on the insulation of the ceiling from the lower floor is carried out in cases of inaccessibility of the attic or during the reconstruction of buildings with finished ceilings from above. This technique involves performing work inside the room under the ceiling. Therefore, you need to free up space inside the room for the installation of scaffolding and their free movement. The stages of the procedure include:

- Installation of the frame type construction from a wooden bar or metal profile.

- Fixation of insulating material in the form of plates, multilayer panels, spraying or mattresses.

- Covering the gap with drywall, boards (particleboard / fiberboard) or plywood sheets.

- Plastering, puttying and decoration of the ceiling plate in accordance with cosmetic repairs.

The disadvantage of this technique is that the insulation layer selects significant volumes from the room space from the ceiling. Compared with the attic option of laying insulation materials, the method is less efficient and more complicated due to high-altitude work. It is often used when attic floors are not available for analysis.

To determine the points of heat outflow from a residential building, you can scan the building from the outside using a thermal imager. Red and yellow marks in the image will indicate where isolation is needed.

If the internal ceiling of the ceiling is wooden, then the surface is treated with antiseptic compounds before work and the slotted holes are closed with foam. When the floors are concrete, the surface of the ceiling is cleaned of decorative coatings and plastered. After that, the slab is coated with primers suitable for cement.

Glue installation of heat insulators

Only those heaters that are made in the form of plates are mounted on adhesive compositions. For attaching to the ceiling, use foam or “liquid nails”. High-speed products are kneaded in small quantities in order to avoid cost overruns and securely fasten the thermal insulation. The glue installation algorithm is as follows:

- The adhesive composition is applied directly to the insulator boards. The surface can be covered completely (for heavy varieties of insulation) or spot (lightweight boards of polystyrene or expanded polystyrene).

- Lay the plates, smeared with glue on the ceiling, alternately, holding in place for 20-30 seconds. When the adhesive solution sets, you can start laying the next sheet.

- For additional strengthening after installation of several insulation plates, they are fixed with dowel nails with a wide hat. This method of mounting significantly increases the reliability of the placement of insulation on the ceiling.

There are gaps between the individual insulator plates. To close them, use foam or putty. Cosmetic closure of the surface includes the installation of reinforcing mesh and plaster or fastening of ceiling sheets. In some cases, preference is given to stretch ceilings. But, we must not forget about the placement of electrical wiring for mounting lighting fixtures.

Before applying the adhesive composition, you need to make sure the compatibility of the insulation material with the components.

Insulation along the guides of the lathing

When it is planned to put a suspended ceiling made of drywall, plywood or lining on top of the insulation, it is recommended to install heat-insulating materials between the frame structure - wooden blocks or metal profiles. Insulation work begins with the marking of the ceiling plate to fix the guides. The further process involves the following algorithm:

- Fastening a wooden or metal frame to the dowel system or suspensions. Between the guides there should be an indent smaller than the width of the insulation plate by 7-10 mm.

- Thermal insulation material is laid end-to-end to the frame. When taking into account the reduced space of the plate, it will jam between the guides on the ceiling. When mineral wool is used as an insulator in mattresses, they are fastened with dowels with a wide hat - umbrellas.

- The gaps between the insulation plates are filled with mounting foam or synthetic filler based on polyester resins - it all depends on the exposure of the insulation material to the compositions of the filling agent.

The vapor barrier film is attached to the ceiling with brackets to the wooden crate and whether double-sided tape to the metal profile. After that, you can start redecorating with laying ceiling structures made of drywall, plywood or lining. If the ceiling is concrete, there are differences in the fixtures of the retaining structure - the option is chosen locally.

The method of laying insulators on top

When laying insulation on the upper side, the choice in materials is wider. This technique has the advantage that it is possible to lay several layers of a heat insulator and additionally provide wind and water protection. When it is decided to use plates made of synthetic material or mineral wool in the form of mattresses, the algorithm of work should correspond to:

- vapor barrier coating;

- laying of plates or mattresses of insulation;

- closing with a waterproofing film;

- closing space with wooden flooring.

If you use mineral wool selected for the size of the gaps, then there are no problems with the issue of gaps. When the slabs are laid, all the remaining slots are filled with mounting foam and cut.

A waterproofing film is laid on top of the insulation coating. Joints in the material are covered with tape or bitumen mastic. The vapor barrier coating is fixed to the surface using an adhesive or construction stapler. The location depends on the type of ceiling structure - for a false ceiling, the best location is indoors, and for a roll-in ceiling between the ceiling and the insulating material. Insulators are laid between the beams of the ceiling, with the expectation of the absence of gaps.

Sprayable heaters

The use of sprayed materials for insulation of ceilings in the house is a quick technique. Polyurethane foam and ecowool are suitable for this procedure from heat insulators. In the case of polyurethane foam, you can lay it on your own only with plates - for liquid spraying you need specialized equipment. Ecowool can be laid without a spray, but the layer will be uneven. The advantages of polyurethane foam are as follows:

- no hydro-steam insulation is needed;

- the material sticks to the surface;

- the coating layer is uniform and dense.

For laying ecowool, you need to use a blowing machine - the material adheres tightly to the floor surface, gradually thickening with a thick layer. If you use such an insulator without equipment, you need to evenly distribute along the ceilings with a layer of at least 10 cm and compact. The procedure is repeated until the desired result is obtained. For ecowool hydro-vapor isolation is obligatory.

To prevent material from getting inside the premises, it is imperative that all slots of the ceiling be covered before application. If polyurethane foam is used, personal protective equipment is needed - a respirator, a chemical suit with a hood, protective gloves and glasses.When laying ecowool, such protective equipment is not required, but you can not inhale the material - it can get into the pulmonary system.

The sprayed compounds, regardless of the speed of application and high thermal insulation qualities, are high in price in comparison with most alternative heaters.

Bulk insulation

Use bulk materials in their state of aggregation is possible only from the attic. Expanded clay, vermiculite, sawdust and other friable substances act as a heat insulator. If natural components are used as an insulator, for example, sawdust, additional measures must be taken to protect them from insects and rodents. You can insulate the ceiling according to this algorithm:

- Analysis of the floor from the attic - if there is a floor covering in such a room, it must be carefully removed. If the boards are pinned with nails, a nail clipper is required.

- Installation of a steam-hydro-insulating layer on the surface. In the process, the film is attached not only to the ceiling, but also to the intermediate beams, taking into account bends.

- Loose heaters are laid in a uniform layer, filling the cells of the ceiling structure to the top - sawdust is treated with flame retardants before that.

- A waterproofing material is mounted on top of the heat insulator. The joints are closed with bitumen mortar and the attic flooring is laid to use the room under the roof.

To protect natural materials from rodent infestation, slaked lime can be added in an amount 5 times smaller than a heat insulator. As an alternative to the bulk method of laying - sawdust can be used as part of a lightweight cement mortar. The mixture is prepared in proportions of 1 part cement to 10 parts sawdust and water is added so that water does not flow out from the resulting composition upon compression.

When there is a choice between types of bulk materials, you need to proceed from the state of overlappings. Sawdust is lightweight, but in the absence of waterproofing it is better to pay attention to synthetic compounds. Expanded clay can be used for a strong wooden house, but this material gives an increased load - there is a risk of damage to the boards before the ceiling breaks down. This insulator is best used on concrete with a cement screed.

Natural bulk materials retain heat better, but most of them carry an increased fire hazard. Non-combustible impregnations are used for protection.

Useful Tips

Insulation of the ceiling can be carried out with various materials of natural and synthetic origin. The most economical option is laying expanded clay (a large load on the floor) or sawdust (fragility), and the best in terms of price to quality ratio is mineral wool. But, regardless of the group of materials and methods of laying the insulation, there are standards that must be strictly observed:

- Hydro-steam insulation is a must when warming the ceiling. If the material is exposed to moisture, then the insulating layer is laid on both sides.

- The insulation layer is calculated based on regional climatic features and thermal insulation properties of materials.

- Heat insulators are laid only on cleaned surfaces, especially when choosing a natural insulation.

To avoid rats or mice becoming overwhelmed, it is recommended to order a disinfestation service before laying heaters. Most synthetic materials are not attacked by rodents, but natural varieties are a convenient place to plant them. If the insulation is placed above the bathroom or kitchen, it is necessary to supplement the system of additional vapor barrier.

Conclusion

In houses of individual construction, they put a cold type of roof, are guided by the principles of economy. There are no problems with heating the house in such cases, especially when warming the ceiling.Experienced builders recommend laying insulating materials from the attic, so there will be no loss of space in the room, and the heat will remain longer. When it is not possible to put insulation from the roof, it is laid from the inside.

Alas, no comments yet. Be the first!