A chimney is a chimney designed to remove smoke from stoves, fireplaces and other heating systems. In addition, a chimney is necessary to ensure the flow of air, without it, fuel will not burn. The chimney device used in modern buildings is very difficult, therefore, it requires careful preparation, design and installation. For the correct installation of chimneys, many factors should be taken into account: pipe material, its height, cross-section, etc.

Content

Chimney Overview

The optimal length of the chimney is about 5-10 m. If it is less than the lower boundary of the specified range, then the draft will be difficult, and a length of more than 10 meters will lead to too much burning and, as a result, to rapid combustion of fuel, and this is completely disadvantageous.

The smoothness of the inner surface of the chimney and the shape of its cross section also significantly affects the draft created. Almost all modern pipes are made of metal, ceramics or combine both materials and have a round cross-section. Importantly, they initially have perfectly smooth walls, while brick chimneys need to be further processed from the inside to achieve the same smoothness.

The chimney device also includes a spark-proof grate, necessary for safety, and a lid that protects against penetration of sediment into the pipe. The desired diameter of the pipe is calculated in accordance with the dimensions of the furnace furnace, fireplace. Do not forget that great attention must be paid to ensuring fire safety and verticality of the channel. Chimneys built into the walls are laid during the construction of the house, and in other versions the pipe is usually laid already along the finished wall.

Chimney construction: features and functionality

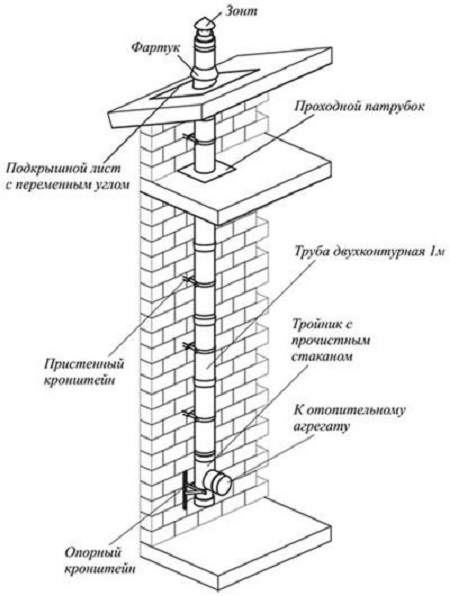

If the chimney adjoins the wall inside or outside the building, use a two-layer pipe (one inside the other, and between them an insulation layer). In addition, it must be bricked or protected with a plasterboard structure, previously insulated.

An outer pipe installed at a distance of 0.1 m from the facade wall does not require insulation.

Ceramic chimneys are now quite popular. They are three-layer structures, consisting of a smooth ceramic pipe with a circular cross-section, protected by heat-insulating plates and external blocks of lightweight concrete. Strength and durability of ceramic pipes should not be questioned (they are resistant to high temperatures and condensate). Such a chimney under proper operating conditions will serve you for at least a quarter of a century.

Ceramic and steel chimneys have the following advantage over brick counterparts: the resistance coefficient of round and smooth pipes is much lower, which means that at the moment of the exit of the flue gases there will be no turbulence.

Chimneys for stoves and fireplaces are built on the basis of the following basic parameters required for calculations. In open brick hearths with a pipe height of 5 m, the internal section should be at least 15% of the cross section of the combustion chamber, and at a height of 10 m - at least 10%. For closed models, manufacturers immediately provide an exit under a standard section (usually 20–25 cm in diameter).

A pipe located within 1.5 m from the ridge should be 0.5 m above it, with a distance of 1.5 to 3 m at the level of the ridge.It is worth noting, thanks to modern devices that reliably protect against external weather conditions, it is not always necessary to adhere to these parameters. For example, it is possible to install a deflector in the chimney, which protects the pipe from precipitation and does not allow the wind to interfere with the exit of flue gases.

Characteristics and installation of chimneys through the wall and roof

Where the chimney is located through the wall, there should be no pipe joints through which communications are passed. The first stage of installation - bringing the chimney pipe to the heating boilers.

The chimney pipe is output at an angle of 90 °.

The next part of the chimney is connected perpendicularly to the installed pipe. A condenser tank is located in its lower section, and the rest of the chimney mass is connected to the upper one.

The passage at the chimney through the wall must be insulated. Best of all with thermal insulation materials. Places where pipes enter and exit are preferably plastered or covered with a protective cover.

The chimney through the wall involves the use of corner joints to better adapt to the architecture of the building. All joints must be fixed with clamps.

Remember, the chimney fasteners must be installed at regular intervals (no more than 1 m; the optimum distance is 60 cm). After installation is complete, caps are installed above the chimney necks. And the pipe itself is necessarily isolated from the wall of the house, for example, with basalt fiber.

Installation of a chimney through a wooden wall has some features. Let's consider them a little more in detail.

First, the pipe will need to be lined with some kind of fireproof material, for example, asbestos or brick.

Secondly, dual-circuit chimney systems are commonly used. That is, they place the pipe in a pipe with a layer of heat-insulating material. Such a system is better protected from mechanical stress and has good thermal insulation.

Thirdly, the chimney, consisting of one long and straight pipe, is best placed vertically and without changing the contour.

Fourthly, it is necessary to use a gate - a special valve to regulate traction.

The chimney through the wall is not the only solution, they also equip the chimney through the roof.

The location of the chimney on a pitched roof is not regulated by the rules. Heating equipment experts advise installing the chimney as close to the ridge as in this case, only a relatively small section of the pipe will be located in the cold zone, which, in turn, will reduce the likelihood of condensation.

Do not install chimneys near the dormers, as flue gases will enter the attic and adversely affect the well-being of the residents of the house.

According to many roofers, it is best to bring the chimney pipe to the roof through the ridge. Since it will not be difficult to make a unit for closing the pipe and cover, and also, there will be no snow pockets. But in this case, it is necessary to build a rafter system without a supporting main ridge beam or to tear the beam with a chimney, mounting supports in places of rupture (and this can not always be done if there is an attic).

Remember, the chimney should not be displayed in the valley. It will be difficult to achieve a tight closure of the pipe and the roofing, and in addition, precipitation collected from the slopes will fall on the pipe. Also, in order to position the chimney in the valley, you will have to greatly complicate the entire roof truss system.

Chimneys for stoves horizontal construction

Unlike vertical, multi-turn horizontal chimneys warm up much more efficiently. The explanation is simple: heated gases rise up, and the horizontal chimney has a larger upper area. That is why when using the same amount of fuel, heating improves. They make such chimneys of brick.

In such chimneys you need to get rid of sharp corners, otherwise there will be turbulences.Use a grinder to smooth.

It is very important to strictly observe the thickness of the seams. In a chimney, even a small difference often leads to a change in its internal section.

Regardless of the shape and material of the pipe, clogging of the chimney fumes is not allowed, otherwise the system will have difficulties with traction. Brick chimneys need to be cleaned and inspected more often than others. Knowing all the nuances of such an action as the installation of the chimney and carefully observing them will help you ensure long uninterrupted operation of the pipe itself and the heating system as a whole.

Alas, no comments yet. Be the first!