Perhaps the main element in the structure of the whole house is its roof. To build it, you need to know the roof structure, its main components, as well as choose the right and optimal roofing materials so that the roof structure lasts for many years and does not leak, and could also save the house from adverse weather conditions.

Most often, to erect a roof frame, use a rafter system. It is quite reliable, tested for centuries, in such a system you can use various types of materials. Of course, the most common rafters made of wood. They are very practical, quite easy to install, unlike metal or reinforced concrete structures. Therefore, even when building houses of brick, a roof device with a rafter system based on hardwood trees is used.

There is a huge variety of types of roofs: single-pitched, double-pitched and others. But most of all, in the construction of residential buildings or private houses, a gable roof structure is used. Therefore, this article will also consider materials and types of rafter systems specifically for this type of roof. Shed roofs are also, of course, used in construction. But they are used in farm buildings, such as sheds, stable and others.

Content

General principles for the installation of rafter systems

Before starting the installation of the rafter system in the roof structure, a block, the so-called Mauerlat, is installed along the perimeter of the building or under each rafter foot. It is laid so that later on top it would be possible to calmly install the rafter system. If the house is built of brick, then the Mauerlat is fixed with special pins.

Having decided on what the roof frame and the angle of inclination will be, you can begin to assemble the extreme rafters. Then you can install the ridge, which will connect the entire rafter structure, then it will be possible to attach intermediate slings to it.

It is very important to check the correctness of their installation in relation to the extreme pairs.

When installing the rafters, the distance between them can be set at your discretion, it can be 60 centimeters and all 90. For a more convenient installation of the entire roof frame, use a board that should be 50 millimeters thick and the width of the board should be from 150 to 200 millimeters . A board with a width of 200 millimeters, without a doubt, will give solidity and strength to the entire rafter system, even if they are built in the northern regions.

The wooden parts of the entire rafter system must be impregnated with special solutions that will ensure fire safety and the inability of the appearance of fungus on wood, as it is obvious that the roof structure must be protected.

The roof device does not have to be exclusively in the shape of a triangle. Simply, this is the most common option, acceptable for installing the rest of the roof elements.

Roof with hanging rafters

Why is this type of rafters called hanging? The answer lies in the fact that such a name appeared due to the fact that the lower part of the rafters sometimes crawls out of the wall and looks like it is “hanging in the air”. Well, so that the sling does not fall, it rests on a beam of wood, which should pass along the perimeter of the entire building.

This roof design allows you to balance all the elements of the roof. Under a load of snow, the roof can carry significant loads. Rafter legs can be compressed quite strongly, but due to the fact that the bottom of the rafters has an emphasis on the Mauerlat, a piece of the beam perfectly dampens the emerging stress under the pressure of snow masses.

If a strong crosswind suddenly blows, then some rafters work in tension, and the lower beam (Mauerlat) - in compression. Thus, the tension, as it were, goes all over the roof, at the same time, without giving out and without destroying the structure of the roof.

Such a roof device makes the walls practically free from the arising loads. The rafter system and the Mauerlat take on the bulk of the load. Only an insignificant part of the loads that are not critical and cannot destroy the structure of the entire building fall on the walls themselves.

If the log house is too large, then a situation may arise in which, without additional supports, the roof structure can be very bent. In tightening, emphasis is also not recommended. What to do in this case? Ancient builders used the so-called "grandmother". This is a special rafter system with a suspension that stretches. "Grandma" is the founder of the first farms.

Farms today, you can call any building structures that are created in order to cover the huge premises in the construction of not only buildings, but also bridges. All the nodes of the roof in this case work according to the principle of the compression process - decompression. This successfully allows the use of small sections in the roof structure in the entire structure of the truss.

Such an extraordinary solution was invented not by any scientist, but by practitioners - carpenters, who thus made some progress in the construction of the roof.

Roofing with rafters

The roof rafters are such a device of the roof of the house, which is quite well able to evenly distribute the load on all nodes of the roof.

Rafters of this type, which rely on a harness made of wood and consisting of a Mauerlat, as well as a rafter beam, can be successfully used for small buildings.

Without internal supports, the layered system is capable of covering only small spans, only no more than 6 meters. In the presence of supporting additional walls, racks can be additionally installed on them, as additional roof elements.

If you use a crossbar during the construction of the layered system, which will tighten the rafters, then in this case the span will increase significantly and can already reach 8 meters or more. And if you use two supports, then the span coverage can be increased to 16 meters.

When constructing a residential building, large-sized spans are not so common, in which case layered structures can be used in almost every private house.

In this type of construction, a roof unit such as a Mauerlat is important. This element protects against the formation of condensation, and also prevents decay of the roof structure where the roof is adjacent to the wall. Therefore, it is important to remember that the Mauerlat must be covered with an insulating layer.

Not only Mauerlat should be isolated. If the wooden floors are in contact with the metal or concrete components of the building, then they also need to be waterproofed. An excellent way out of this situation is the use of roofing material in two layers. The material is not very expensive, but quite practical.

Installation of a layered rafter system

The correct fixing of the rafters on the rafter beam is one of the most important points in the installation work of the entire roof device.

The Mauerlat itself must be very securely attached. Usually, these roof elements are fixed with metal pins that are concrete in the wall. The landing depth should be at least 40 centimeters.In other cases, bolts are used, which are also concreted into the walls.

The way rafters are correctly fixed to the rafter beam is a very important point when installing an overhead roofing system.

First of all, the Mauerlat itself must be securely fixed, for this they use either metal pins concreted into the wall to a depth of at least 40 cm, or bolts fixed in the same way.

Roofing elements such as staples that attach the rafters themselves to the Mauerlat are often used. Mauerlat is a bar, the sides of which are 140-160 millimeters.

Most often in the construction of houses and the construction of rafter systems, it is wood that is used as the material. It is easy to install material. The construction of a house roof using concrete or metal rafter systems in private construction is an extremely rare phenomenon.

To fasten the elements of the roof, as well as slings, use compounds such as spikes, teeth and baking sheets.

To install the rafters as correctly as possible, you need to carefully calculate all the loads that will affect the roof, and only then approach the installation.

When erecting a roof on damp log cabins, installing rafter systems in the roof frame requires special attention.

If the log house is wet, then you need to pay attention to the so-called shrinkage coefficient. It can in different cases be from 4 to 6 percent or more. This must be taken into account when installing the roof, since in a year such a frame can dry out and decrease by 15 - 20 centimeters.

Many construction companies usually take this information into account and propose house designs where the roof device has several options, including “shrink”. To find the necessary information on this issue, it is enough to search the Internet using a query, for example, “operated roofing device”.

There are several ways to solve this problem. You can install rafters, in the design of which there will be "sliding" supports. In other cases, install shrink compensators under all supports based on jack bolts.

Everything is clear about the shortcomings of the first method, too long a wait. Bolted jacks are a good option, but they require, if not surgical accuracy, then very close to this. In this case, the most advantageous is the installation of sliding mounts.

Sliding fastenings are also good because even after shrinkage occurs, a tree is such a material that it will still gradually change over time. And although these changes will be very minor, but they will be permanent, and therefore the installation of sliding structures will be very welcome.

Here's what this mount looks like in general terms. On the Mauerlat, which ensures that the roof adjoins the wall, a bar is stuffed at a certain angle, or the Mauerlat itself is made of the desired shape. Then fix the corner, which has some bend. A special embossed plate is installed under this curved structure.

Since it is assumed that the sliding path will be directed outward, this relief plate is best secured to the rafters so that there is as much free distance as possible for the course towards the building ridge.

It is worth considering the fact that the rafters must rest on a beam, the structure can be movable, but another movable element should be a hinge in the ridge.

Rafter rafters may have a butt joint with each other, it is necessary to use metal plates. The roof device should be such that there is a certain angle at the ends. This is necessary in the case when the rafters need to be moved so that they would not be too close to each other. With the second mounting option in the pad, you can connect the rafters and fasten them to the bolts.

Structures of rafters

Rafter systems, the roof units of which contain hinged elements or a floating connection, can be attributed to such a type of joints as non-supported.

In such joints, the load does not completely fall on the Mauerlat and other wall structures. Another thing is spacer systems. Here, the ridge connection is usually very firmly fixed, while the support, which is attached to the Mauerlat with a hinge, as an option, can be a “tooth” connection, then the load also falls on the walls.

A rafter system of this type can be considered hybrid, because it uses elements of both layered and hanging systems.

But since the legs of the rafters take on all the main load, in this method of fastening the ridge beam becomes an almost optional element of the system.

When installing the system on spacers, the holes in the joints of the bolts should be few millimeters smaller than the diameter of the bolts to be fixed. If the holes are too large, then it may happen that under the influence of the loads the Mauerlat will be damaged, and this can adversely affect the entire roof frame.

In those times when there is no snow and other harmful weather influences, with an unloaded condition and with the correct installation of rafter systems, the load on all nodes of the roof should be approximately the same. But in winter, the load on each of the slopes can vary significantly, and this is also important to remember.

With improper installation of rafters, a shift of the entire roof structure can occur, and in some cases lead to complete collapse.

Variety of materials for roofing

A variety of roofing materials on the market, with which the roof is finished, can amaze anyone inexperienced in building people, because depending on the type of structure you can use certain materials that are optimally suited for the tasks to be solved. It is necessary to carefully approach the issue of material selection, while taking into account factors such as the type of roof structure, roof structure, expected loads, and also know the abilities of load-bearing walls and floors.

At the moment, there are two divisions of roofing materials:

- soft roofing materials;

- hard roofing materials.

In each of these categories there are dozens of names of names and firms, which are easy to get confused in. Let us consider only the most basic materials from two groups, and the areas of their application for the tasks to be solved.

Soft roofing materials firms, manufacturers of rolled types, a great many. It is important to remember only that these materials, as a rule, serve for waterproofing. These are excellent materials for concrete or other types of solid roofs when building a house roof.

Soft materials are also subdivided into two types, depending on the basis of which they consist:

- bituminous;

- polymer;

- bitumen-polymer.

Whatever basis they contain, they have one property common to all, namely, the method of application. Exceptionally all soft materials are applied by welding to the entire roof frame, but before this process, the entire roof must be treated with mastics special for these cases.

This type of material has significant drawbacks. Finishing the roof with such materials makes it unstable to various weather conditions, for example, to sunlight or to high temperatures. From adverse effects, the material can dry out and crack, and this, naturally, adversely affects the entire roof, as its tightness is violated.

The main soft roofing materials include roofing material, ondulin, flexible tiles.

Rigid roofing materials are more reliable in operation, and, perhaps, one of the best advantages of this type of materials is that they have a very long service life.

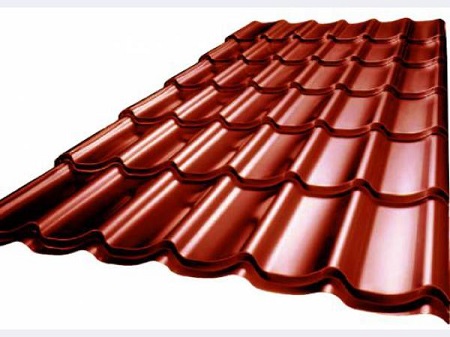

Such materials, with proper installation and care, can last at least 30 years, and in some cases, much more. The most striking representatives of this type of roofing materials include metal tiles, seam roofs, corrugated roofing, copper roofing.

When deciding on what type of roofing material is required for installation on the roof frame, you should not buy only those materials that are the most expensive. A high price is not always an indicator of the quality of a product. You need to choose the ratio of price - quality according to the criteria, and in order to make the right and informed choice, you need to study the full range of goods on the market.

It is worth noting that, depending on the choice of a building material for building the roof of the house, you can calculate the estimated load in advance, determine the type and type of roof systems, and then the erected roof will be a reliable protector from any weather, creating coziness and warmth of the family hearth!

Alas, no comments yet. Be the first!