The production of almost all goods in our country is carried out in accordance with established quality standards, and the I-beam is no exception - GOST 8239 89 governs the production of hot-rolled steel I-beams. There are several more GOSTs for the production of I-beams, they will also be discussed in today's article. Before proceeding to describe the requirements of GOSTs and enumerate the necessary parameters for these metal products, we should briefly talk about I-beams and their fields of application.

Content

Briefly about the I-beam and its assortment

I-beams are the most common type of steel beams. They are extremely widely used in both industrial and civil engineering. That's why it is not surprising that modern manufacturers offer such a huge assortment of I-beams. A distinctive feature of the I-beam is the cross section, which consists of two shelves and a wall located between them. This type of section allows the I-beams to create an increased level of mechanical rigidity. Due to this, I-beams are an ideal structural element for solving various problems where significant resistance to bending and loads is required. For example, I-beams are used in the construction of ceilings, bridges, columns of metal structures and other complex elements. The vast scope of application led to the presence of a wide range of I-beams.

The assortment of the I-beam is very strictly regulated by the state and is the same for all manufacturers. That is, regardless of the manufacturing plant, the beams must comply with certain established requirements, and its parameters must be within the existing regulatory values.

GOST 8231-89: modern requirements for I-beams

The first mentioned standard, GOST 8283-89 with the official name “Hot-rolled I-Beams,” was developed back in the USSR and is currently in force in our country, that is, all manufacturers of I-beams should focus on it. It entered into force on July 1, 1990.

In accordance with the decree, the cross-section of the I-beam should be as in the drawing below, and the slope of the internal faces should be in the range from 6 to 12%.

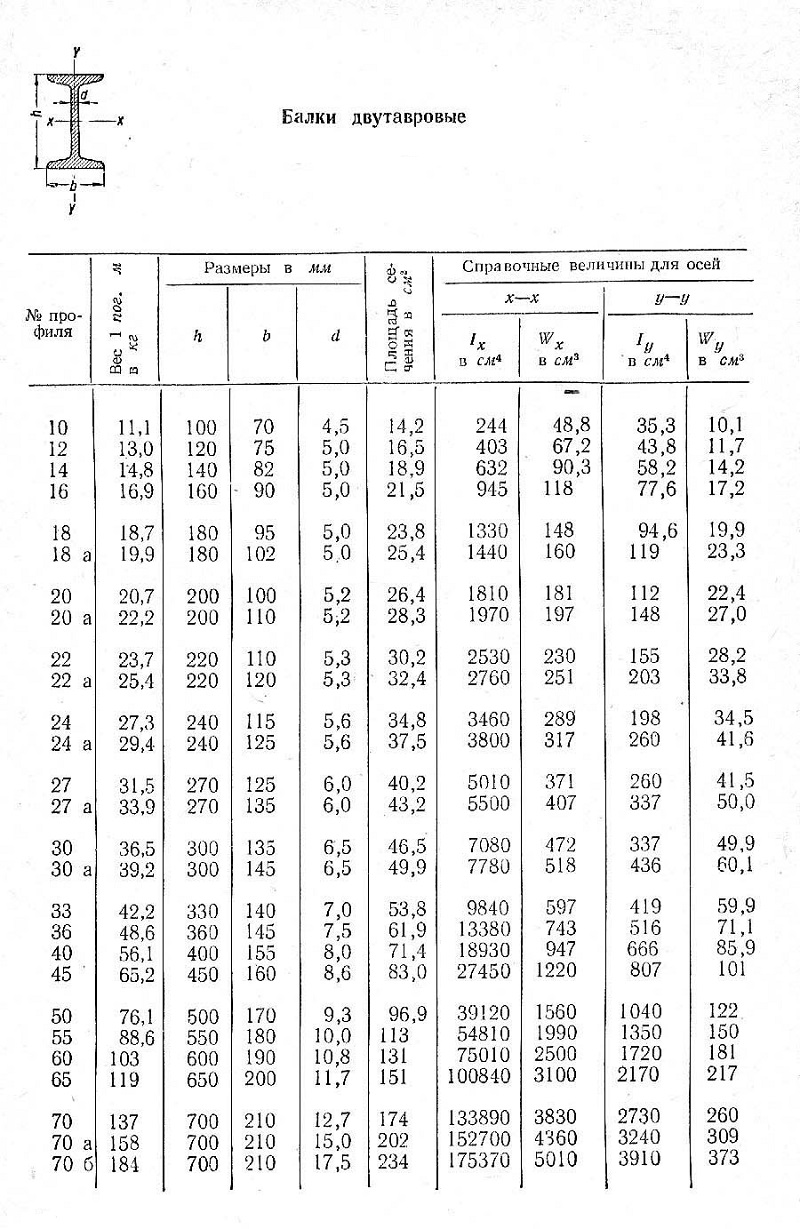

A table with the main parameters (the height of the I-beam, the width of its shelf, the thickness of the walls and the shelf, the moment of inertia, the moment of resistance, the static moment of half section, the radius of inertia) is given. You can see for yourself what characteristics correspond to each profile number.

Notes to the drawing and table:

- when calculating the cross-sectional area and mass of 1 m of the I-beam, the nominal dimensions were used, and the density was taken equal to 7.85 g / cm3;

- the radius of curvature of the I-beam, the slope of the inner faces, the thickness of the shelves are given for the correct construction of calibers, but are not controlled at the box office;

- Profile numbers from 24 to 60 are not recommended for use in new designs.

According to the accuracy of rolling, the I-beams are classified into: beams with increased (B) and ordinary (C) accuracy. Accuracy is selected depending on the scope of the I-beam (the GOST range requires this). So, for house building, you can choose type B, but, for example, for the construction of mines it is better to stop on type B.The maximum possible deviations in size and cross-sectional shapes should correspond to those indicated in the table below.

The deflection of the beam wall cannot exceed 0.15 of its area, and the curvature of 0.2% of its length. The blunting of the outer edges of the I-beam shelves with increased accuracy should not be more than 2.2 mm, and for I-beams with normal accuracy this parameter is not controlled.

The length of the manufactured profiles varies from 4 to 12 meters. Beams with a length of more than 12 meters are less reliable. Classification of I-beams according to the length of the beam: I-beams with measured, multiple measured and unmeasured lengths.

At the request of the consumer and the corresponding capabilities of the manufacturer, the profiles can be more than 12 m.

Deviations in the mass are also strictly regulated. The declared mass may be exceeded by no more than 3%, but may be less than not more than 5%. By agreement with the consumer, the mass can also be slightly changed (if this does not go to the detriment of the rigidity and reliability of the structure). The size, geometric shape of the beam is controlled at a distance of at least 5 cm from its end.

Range of rolled steel in accordance with GOST 8239-72

The I-beam in accordance with this standard should not differ much from the above, since the latter is its immediate predecessor. GOST 8239-72 was adopted in 1972, also back in Soviet times. That is why the standards are largely preserved. A table with typical parameters is shown below.

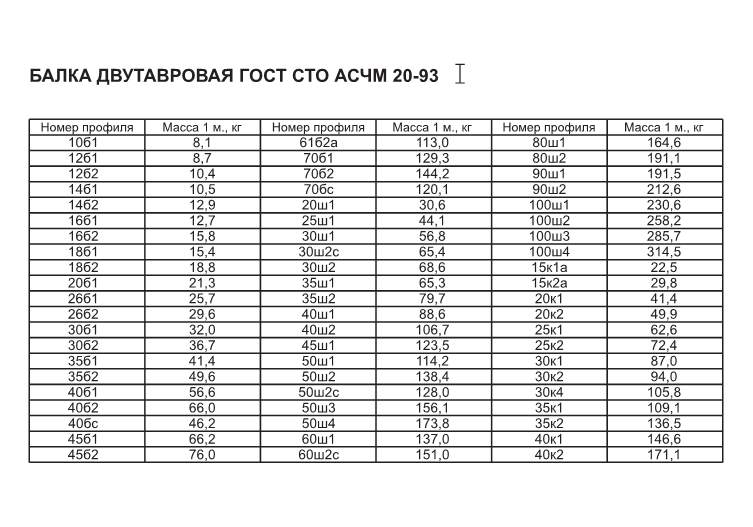

I-beam STO AISU 20 93: main parameters and requirements

STO ASChM 20-93 “Rolled steel high-quality shaped profile. Hot-rolled I-beams with parallel flange faces ”is no longer a GOST, but introduces certain technical conditions for the production of products made of unalloyed and low alloy steel. The beginning of action is January 1, 1994.

The main regulatory acts on which this regulation is based are as follows:

- GOST 535-88 "Long products and shapes from carbon steel of ordinary quality." General specifications.

- GOST 19281-89 "Rolled steel of high strength." General specifications.

- GOST 27772-88 "Hire for building steel structures." General specifications.

- GOST 7566-81 "Hire and products of further processing". Rules for acceptance, labeling, packaging, transportation and storage.

In accordance with STO AISU 20-93, the following assortment is distinguished. By ratio The sizes and shapes of the profile of the I-beams are divided into 3 types: normal (B) with parallel faces of the shelves; broad-shelled (W) with parallel flange faces (have a longer flange length than normal); columned (K) with parallel flange flanges (have a larger flange thickness; the heaviest type of beams, but also the most wear-resistant).

A drawing of a typical I-beam, described in the regulations, you can see in the diagram. Designations are used the same as in GOST 8239-89. Notes also match (except for the last paragraph). Tables with values are given.

Possible blunting of the corners of the shelves should be no more than 3 mm, which is ensured by a special rolling technology. Already on the profile, this indicator is not checked, since it is not fundamental in construction.

For maximum deviations in size and cross-sectional shape, a table with calculated values is also compiled.

The length of an I-beam is the length of a conditionally cut beam with perpendicular ends. I-beams of measured length are as follows: 9, 10, 12, 15, 18, 24 meters, but, at the request of the customer, it is possible to produce beams with a different measured length ranging from 8 to 24 m, the interval of intermediate sizes should be 0.1 m . Beams of unmeasured length or of a length limited to unmeasured are made in the range from 4 to 24 m. Large sizes of beams are unreliable and therefore are not produced.

The curvature of an I-beam cannot exceed 0.2% of its total length. At the request of the client, I-beams with a height of more than 300 mm are produced with a curvature not exceeding 0.1% of the beam length. Such orders are discussed individually.

If the consumer requires, it is possible to produce beams with a mass having deviations from the standard by no more than 4%.

It is very important that the product does not have defects on the surface, which may interfere with their further use, as well as spoil the appearance of the product. Damage greater than 1.5 cm is not allowed.2; pollution; deep cracks and chips; sunsets with a depth of more than 1 mm, if the thickness of the profile element is less than 10 mm, and a depth of more than 2 mm - with a thickness of the profile element over 10 mm.

The surface can be cleaned of defects or cut down with the obligatory ensuring a smooth transition (that is, sudden contour changes are not allowed). The depth of stripping or cutting cannot exceed:

- 1 mm - for a profile with a thickness of up to 10 mm;

- 2 mm - for a profile with a thickness of more than 10 mm.

There may be nicks at the ends of the beams, but they should not exceed half the actual length deviation, as well as burrs.

If required by the consumer, the manufacturer must remove the burrs from the surface.

At the request of the client, marking on the product is carried out with indelible paint of various colors (permissible colors are given in the position itself).

There should be no delamination at the ends of the beams, otherwise the quality of the structure as a whole may suffer!

The size of the beams is checked at a distance of at least 5 cm from the ends of the profiles. Wall thickness is measured at the end of the product.

In order to carry out mechanical properties control, as well as cold bending tests, various statistical non-destructive methods can be used, agreed and approved by certification authorities.

I-beam standard with parallel flange faces

There are a great many metal products for construction, but since today we are only talking about an I-beam, GOST 26020 83 is the last, which will be considered in this article. This GOST came into force on January 1, 1986. As you already noticed, all the standards currently in force were adopted back in the USSR, which is a guarantee of quality and reliability.

This standard applies to hot-rolled steel I-beams with parallel flange faces with a height of 100 to 1000 mm and a shelf width of 55 to 400 mm.

According to the ratio of parameters and conditions for the use of beams, it is customary to subdivide into the following types: normal (B), wide-shelf (W), columned (K) I-beams. All of these varieties have already been mentioned above, so we will not repeat.

The cross-section of the beams is indicated in the diagram above.

All acceptable beam sizes, cross-sectional areas, linear density, other reference values are given in a special table.

The maximum permissible deviations in size, geometric shape of products cannot exceed the values given in the following table.

The notes to the tables and designations indicated in the very first described GOST are also valid for the one considered in this section.

The curvature of the profiles in the vertical and horizontal planes cannot exceed 0.001 for a height greater than 310 mm.

The lengths of the I-beams can be the same as described in the paragraph above.

In this GOST there is a new concept of “length” of length. So, beams with a length of at least: 3 m are considered a segment (for profiles with a linear density of up to 20 kg / m); 4 m (for products with a linear density of over 20 kg / m.).

For I-beams with a measured length with a segment and with a multiple measured length with a segment, segments in the following volumes are allowed:

- up to 5% of the total mass of the batch (for products with a linear density of up to 20 kg / m);

- up to 8% (linear density from 20 to 50 kg / m);

- up to 12% (density from 50 to 150 kg / m);

- up to 20% (density more than 150 kg / m).

Assume that beams of limited length within unmeasured can be made.

The maximum possible deviations in the length of the measured and multiple measured length profiles in no case may exceed the values indicated in the special table.

Kosina reza cannot derive the length of an I-beam beyond the limit deviations along its length.

The blunting surface must be convex and have no ledges. The blunting radius is not more than 0.2 of the thickness of the shelf and not more than 3 mm.

Verification of compliance with the dimensions should be carried out at a distance of at least 5 cm from the ends of the profile.

This article talked about a huge number of technical specifications per I-beam. GOST and its description require this. Do not be alarmed if you come across many previously unfamiliar words. Everything is quite simple, you just want to understand the topic better.

Alas, no comments yet. Be the first!