Proper arrangement of the ventilation system (CB) in apartment buildings and private residential buildings ensures a normal atmosphere and clean air, with minimal heat loss in winter. To carry out calculations on ventilation, knowledge about the features of the systems and the general rules and norms of the device according to SNiP are necessary. It will not work out independently to develop and install a ventilation system - it is easier to make an exhaust through a wall in a private house with your own hands.

Content

What is ventilation for?

Air quality in residential premises according to state standards and norms of SNiP should ensure normal human habitation. In order for the microclimate indicators in a private house to comply with the norm, it is necessary to provide a ventilation system. To do this, take into account the total area of housing, types of thermal household appliances, temperature indicators, humidity and environmental pollution in the territory of the building. SV should provide such a number of factors:

- The removal of polluted air into the street along with dust, combustion products and carbon dioxide.

- An influx of fresh clean air saturated with oxygen from the side of the street instead of the withdrawn one.

- Preservation of temperature and total humidity in the room as part of the norm.

There are no alternative devices for observing such conditions for a residential building. Cleaning filter systems built into air conditioners, ionizers and humidifiers cannot ensure the condition of the air in the house according to the standards of sanitary rules. In addition to the expended and polluted air in the room there are also exhaust gases from the boiler, oven and stove in the kitchen. With a constant stay at home, the air undergoes such a series of changes:

- The composition contains an admixture of toxic components - fumes from certain types of coatings and materials.

- Burning oxygen during the breathing of residents, including pets, and the production of carbon dioxide with an increase in total humidity.

- Open and closed heat sources burn oxygen and fill the surrounding space with combustion products.

- Woolen and textile household items are also dangerous due to the accumulation of the smallest particles of material in the air.

- The presence of animals and vegetation in the room leads to the presence of particles of wool and toxins from individual colors in the air.

Individual inclusions carry an indirect danger - allergic reactions may develop.

These points are not a reason for refusing to keep pets or the use of heaters and stoves. Danger to humans arises only with a significant concentration of foreign matter in the air. To maintain cleanliness, it is enough to equip the housing with an appropriate ventilation system, for which you need to follow the norms.

Types of hoods in a private house

To provide residential buildings with ventilation, different systems are used.The main division is carried out on the supply and output, as well as natural and forced. The supply air supply means only the supply of fresh air to the room, and the exhaust provides air purification. A separate version of the system is ventilation with recirculation. These types of ventilation supply air to the house from the exhaust channel when mixed with outdoor, so heating to the desired temperature occurs.

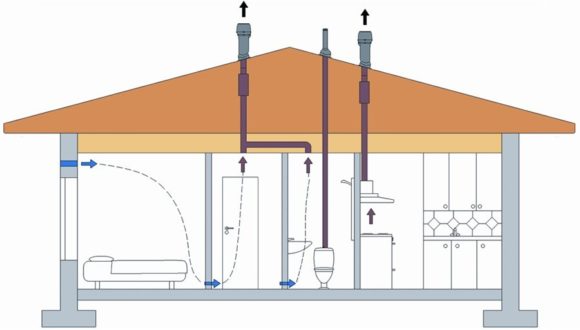

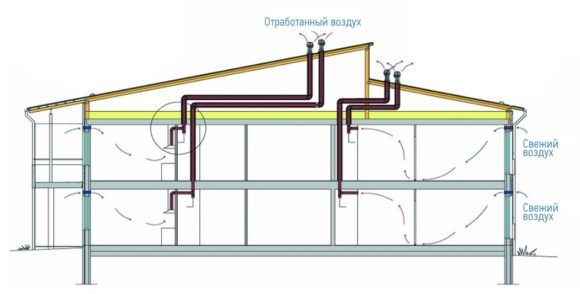

To maintain established standards according to GOST, the ventilation system of a private house should provide continuous circulation of air masses with replacement. For example, for a bedroom or a living room, a classification is assigned a value of 1. This means that the ventilation system for the room should provide a complete change in air volumes in 1 hour. According to the air replacement system, 2 types are considered - with natural traction and forced CB.

A separate kind of room ventilation system is a chimney, which should ensure the removal of combustion products from heating appliances - a stove or boiler, both solid fuel and gas. With a natural outflow system, substitution occurs due to the greater density and severity of the cold air, which displaces the heated indoor. The rate of substitution in such a SW is negligible. If there are segments of the ventilation course in a horizontal position over 8 meters, it is better to use forced systems.

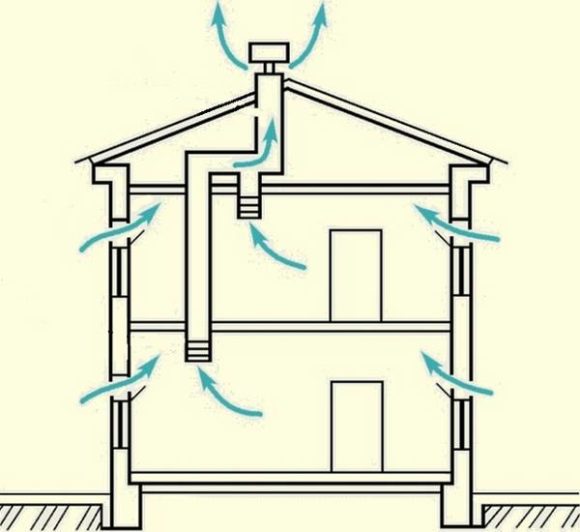

CB natural circulation can be channel and non-channel. In the second case, you need to open window openings and doors to refresh the air in the building.

The forced circulation device provides a high rate of air replacement in the room, because it can be used in houses of a larger area. Air ducts in such CBs are installed under the roof, and they have a large length over the building. Such systems can be provided with additional devices for purification of supply air and recirculation.

Types of chimney ventilation

It is necessary to choose the material for the exhaust duct based on its original purpose and the features of the proposed device of the ventilation system. According to the purpose of the channel, the output of the exhausted air masses from heating devices is distinguished - a boiler, gas column, etc., or the general provision of indoor air. You can choose from the following:

- steel pipes;

- brickwork;

- ceramic duct;

- coaxial chimney.

To correctly determine the material for the ventilation system device, you also need to take into account the initial design of the structure. Channels from certain types of material need to be prepared at the construction stage. For the organization of air supply for residential premises, temperature stability is not needed, so you can use the simplest ones, including plastic.

Brick usage

Brick is the most common material for ventilation shafts. But, when using it, it will not be possible to save, since it is suitable only for heated systems - if there is no heat, condensation will form inside the mine. It leads to a violation of the structure of the material, so on the inner side you need to lay an additional layer.

If it is planned to use a brick shaft to ensure the outflow of gases from the boiler or to provide general air in the house, an internal layer must be provided. As such, galvanized steel pipes are usually used. Conventional masonry is more suitable for a wood or coal stove - hot air and soot will block the brick from exposure to dampness.

The thickness of the walls of the inner pipe in a brick mine is determined by the estimated temperature of the exhaust gases - higher temperature, greater thickness.

Steel pipes

Steel pipes are easy to install, especially when compared to masonry. The wall thickness of such an exhaust channel is selected depending on the expected temperature of the exhaust gases.For a gas boiler in a private house, this figure will be about 400-450 ° C - the walls should be 0.5-0.6 mm thick. For solid fuel furnaces and boilers this will not be enough - the pipes will burn out in a short period. It is better to choose steel during reconstruction or when there is no other option. The assembly of such a chimney is carried out as follows:

- Segments install the pipe into the pipe, for which expansion and contraction at the ends are provided. Begin assembly from the bottom.

- For the convenience of cleaning the chimney, it is necessary to foresee the installation of inspection wells in advance - a distance of not more than 2 m.

- For the stability of the system, it is fixed with brackets every 1.5 m. So, there will be at least 1 for each segment.

- During the preparation of the project take into account that the horizontal parts should not be longer than 1 m with natural traction.

You can buy different types of pipes in diameter, but there is also a difference in the structural structure - single-circuit and double-circuit. Single-circuit pipe - a single-wall channel made only of steel with a possible zinc coating. Bypass structures are reminiscent of a sandwich - two pipes with different diameters are inserted one into the other, the gap is filled with refractory material, often with basalt wool.

The use of ceramics

Ceramic channels of the boiler outlet are considered the most reliable when using solid fuel with plans for the transition to a gas system. The main advantages of the material are durability, ease of cleaning and gas resistance. Ceramic pipes do not allow exhaust gases and provide safety from toxic compounds in the living room.

Ceramics also have disadvantages - fragility and susceptibility to moisture. To protect the chimney from this material, it is recommended to install condensate drainage devices on the outside. In its pure form, a ceramic tube for the chimney is not used - it is supplemented with a heat insulator and a more stable expanded clay shell. Alternatively, ceramics can be installed in a brick channel.

As an insulator for such a chimney, it is recommended to use basalt cotton wool or other non-combustible varieties of insulation.

Coaxial Chimney Application

When designing the chimney support of a gas boiler, it is better to pay attention to coaxial type systems. The structure of such a chimney involves the location of the pipe inside the pipe with a free gap. The central channel is designed for the removal of gaseous products of combustion, and the external one for the flow of oxygen into the closed combustion chambers of gas boilers. The advantages of a coaxial system are as follows:

- The supply air cools the exhaust gases in the chimney along the way. This increases the fire safety of the system.

- The intake air is preheated by exhaust gases. Due to this heating, the efficiency of the heating system increases.

- With an increase in efficiency, more fuel burns, because there are fewer toxic compounds in the exhaust gases.

When installing a coaxial chimney, do not put more than 2 bends - the supply air will be delayed, as will the flue gases. Horizontal pipe placement is not recommended without forced traction. When several boilers are installed in a building, it is impossible to use a single coaxial type chimney - it is better to form separate systems.

Methodology for calculating ventilation

The calculation of the ventilation system of a private house in comparison with the systems of multi-apartment buildings is simpler, since fewer rooms are needed for maintenance. The methodology is regulated by the legislation of SNiP and includes taking into account a certain list of characteristics, since the layout of the room and the arrangement of furniture noticeably affect the flows. Approximate characteristics of air exchange can be obtained by the free area of the room or by taking into account other conventions:

- For a living room, the area of which does not exceed 20 m2, the ventilation rate will be about 3 m3 / hour.

- With large dimensions of the room, they calculate based on the number of residents - for 1 person, air exchange of 30 m3 / hour is needed.

- For premises with auxiliary orientation - workshops, pantries and a kitchen, an influx of 110 m3 / hour is required.

When a gas type stove is installed in the kitchen, the increased oxygen consumption must be taken into account. In such cases, the calculation uses the minimum value of 140 m3 / hour.

Such calculations are applicable only when developing a ventilation system of natural flow in ideal conditions. Therefore, in the calculations, it is necessary to take into account the heating system and the total energy consumption when ventilating rooms in the house. Even when optimal air exchange characteristics are achieved, in some cases it is necessary to take care of the additional heating of the incoming flow.

Standards for the construction of a private house

If it is necessary to install CB in a private house, sanitary - technical requirements for the device should be taken into account. This is due to ensuring healthy air exchange and the general regulation of temperature in the living room. The main rule is the correspondence of the output stream to the supply. In the event of a significant imbalance in the house there will be drafts and odors from the street. In addition, you need to take into account such norms:

- The walls of the CB channels should be smooth. To do this, I use pipes of circular or square cross section with a constant size.

- The common ventilation riser must be equipped with a viewing window. This hole is sealed tightly.

- The exhaust duct should rise above the roof by at least 1.5 m. If the roof is of a non-standard shape, deflectors are installed to protect against backdraft.

- When the design of the house did not initially include a ventilation system, you need to build an additional channel. It is insulated for stable traction.

- Forced exhaust equipment in the kitchen cannot be combined with the natural ventilation of the rest of the house. There may be problems with circulation in the rooms.

- The maximum distance from the ceiling to the edge of the outlet ventilation path must not exceed 15 cm. An increase entails air stagnation at the ceiling.

The internal openings at the interior doors must be permeable to the circulation of air masses even when closed. When installing solid panels, the distance to the floor is at least 2 cm. If there is no way to leave a gap, it is better to buy doors with a finished grille near the floor. When the circulation is disturbed, an imbalance between the supply and exhaust air volumes also occurs.

When the gap under the door cannot be left and there is no way to replace the door leaf, as a temporary solution it is recommended to drill holes in the lower part.

Natural air exchange

Classic home designs include natural air exchange systems. This type of ventilation works on the physical properties of gaseous substances - warm air rises and leaves through the outlet channel, simultaneously pulling fresh through the supply channels. The following factors indicate the inefficiency of the ventilation system of natural circulation:

- dustiness of rooms;

- lack of oxygen;

- high humidity in winter;

- air dryness in summer;

- the development of mold under the wallpaper;

- soot settling on walls and ceilings;

- fogging of glasses in frames.

If such effects are constantly observed, then you need to check the operability of the ventilation system and pay attention to the possibility of installing forced ventilation. It is not difficult to check the operation of the exhaust ventilation duct - for this, bring a lit match or a sheet of paper to the hole and observe the behavior. During normal operation of the hood, the flame or paper will deflect toward the channel. If such an effect is not observed, then we can conclude that it is necessary to clean the ventilation passages.

Features of work

After calculating the nominal air exchange of a private house when choosing a natural type of NE, prepare a sketch of the placement of channels and points of the incoming and outgoing flow. Most of the buildings of individual construction are located outside the city limits, so filtering components, as well as forced circulation, are not needed. If plastic windows are installed, this is a big obstacle to natural circulation. With limited air exchange due to deaf frames, supply air valves must be installed. Their device is as follows:

- straight pipe with smooth walls;

- the length corresponds to the thickness of the window frame or wall;

- there are lattices from the outside and inside.

The permeability of the inner side of the valve is controlled by a grill - the channel can be completely or partially blocked.

Such input channels are placed at the top of the window so that fresh air warms up due to internal heat. If the valve is placed in the lower part, then it is placed behind the radiator - heat from the heating system warms up the incoming stream. When adjusting the NE, the inflow and outflow are directed so that fresh air passes from the main living quarters to the "dirty" ones - the kitchen, toilet, workshops, and pantries.

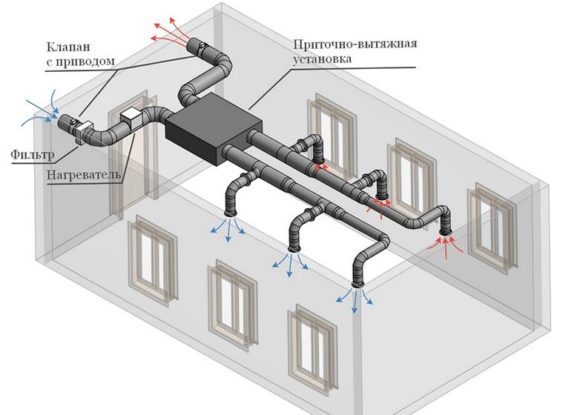

Mounting forced CB

The operation of forced ventilation systems is based on the additional provision of an exhaust duct with a fan. This option allows you to more effectively replace the air in the room, regardless of weather conditions with the ability to control air exchange. How the disadvantages are identified is the dependence on power supply and the need for periodic replacement of the filtering part of the system. Forced SV are:

- typesetting and supply;

- exhaust;

- supply and exhaust;

- ducted air conditioners.

The most effective option is recognized as supply and exhaust SV. The design includes a set of sensors, filters, automated valves and a single ventilation unit. Strong cooling of the air in a room with a supply and exhaust system is prevented by a special damper, which automatically activates when the temperature in a ventilated room drops significantly. With a small area of a private house (2-3 living rooms), builders recommend installing an SV processing from 200 to 300 m3 / hour.

Combination of ventilation with recirculation

CB based on combining ventilation with recirculation works on the principle of combined flow - part of the fresh air comes from the street, and part is filtered internal. Such a system makes the air fresh and reduces the cooling of the room, but can provide only 1 room. The main disadvantages of this option are the limited use of SNiP and low productivity in cold regions. Positive aspects of combined CB:

- saving on air heating costs;

- the ability to control recirculated volume;

- Switching from one system to another.

By adjusting the SV valves, the best characteristics are obtained for the warmth and freshness of the air masses in the house for normal life.

The technique of installing the hood in the kitchen of a private house

After calculating the parameters and buying an exhaust system for outflow equipment in the kitchen in a private house, the installation work must be carried out correctly. There may be differences in steps depending on the model and functionality of the hood, but the general algorithm is not different. In addition to the device and the attached parts for installing the exhaust system, the following list of tools and consumables is required:

- construction level;

- hammer drill;

- hacksaw for metal;

- screwdriver;

- set of hand screwdrivers;

- tape measure or folding meter;

- silicone sealant;

- putty.

A cooker hood is supposed to be installed 50-70 cm above a gas stove or electric. With this arrangement of the assembly channel, all the fumes will enter the system and the smell will not be retained in the room.When installing the dome is mounted on the wall or kitchen cabinet in accordance with the instructions. The output channel is recommended not to be connected to the general ventilation system (if the kitchen was not included in the calculations), but to be routed to the street with a sleeve. Regardless of the type of system, it must be cleaned of impurities; in recycling models, a filter replacement is also provided.

Forced bathroom ventilation

To ventilate the bathrooms in the house, a natural inflow through the cracks under the doors or vents is used. If necessary, a forced circulation is carried out the installation of a ventilation exhaust system with fans suitable for humid environments. The shaft of the ventilation system was originally laid in the classic design of the house - usually a pipe 11 cm in diameter acts as a channel. Installing a fan consists of the following procedure:

- In the bathroom in a private house, an additional power source for the fan is supplied.

- A hole is punched in the wall corresponding to the hood coupler.

- The fan clutch is installed in the hole and the fasteners are prepared.

- The fan is disconnected from the front panel, and connected to the mains.

- Install the hood on the wall with a mount to the adapter sleeve.

- The removed panel and grille are replaced and the system checked.

If there is no necessary provision for forced extraction in the bathroom, then you need to install a pipe that is close in size and through the outer wall to bring the channel above the roof level.

Basement or basement ventilation

To keep dry and cool air in the basement, it is necessary to ensure its complete replacement once every 30 seconds. Due to the low location with a small basement area, natural ventilation is suitable. To install such a system, it is necessary to install a thermally insulated pipe with a diameter of 8 to 15 cm. The inlet channel is placed along the outer wall - 30 cm from the floor inside the room, and outside the pipe should be 5.5 meters. For a small basement, such a system would be enough.

If the basement is large in area, in addition to the supply duct, an exhaust is installed. Outflow is mounted under the ceiling - air exchange occurs due to temperature differences in the street and in the basement. To adjust the air flow into the room, it is necessary to provide a difference in height from the outside - the higher the outflow channel is located, the more powerful the air flow. At the ends of the pipes, grilles must be installed to protect against debris and rodents and visors from rain.

Mounting the hood for the boiler

An extract in the boiler room in a private house is a necessity, since the burnt out air in the room must be replaced with fresh. Before installing the hood for the boiler, you need to calculate the security parameters. To do this, collect data on the location of the house, the area of the boiler room and the capacity of the boiler. In order to provide the boiler with the required volumes of air by natural influx, the following parameters must be observed:

- The location of the house on a hill or plain.

- The absence of barriers at the level of the output channel - tall houses or trees.

- Low boiler capacity and boiler room area.

The exhaust pipe in this case is placed above the boiler and the chimney is removed above the roof, so natural draft will be ensured. If the passage of the ventilation duct through the building is unavailable, it is led out through the wall and increased to the desired level. The air flow into the room is provided by an open window, a transfer grill in the door leaf or microventilation of the window opening. When the parameters of the house are not suitable for installing a natural hood, you need to pay attention to forced circuits - the level of the output channel does not matter, the main thing is to leave the exhaust fan.

The inflow with forced ventilation of the boiler room is arranged by analogy with the option in the natural ventilation of this room.

Conclusion

Properly executed ventilation scheme allows you to provide housing with fresh air without loss of comfort both in the warm season and in winter. Depending on the structure, you can choose naturally forced ventilation and forced ventilation. To install a ventilation system in a private house with your own hands, you must first calculate the supply parameters and prepare the materials.

Alas, no comments yet. Be the first!